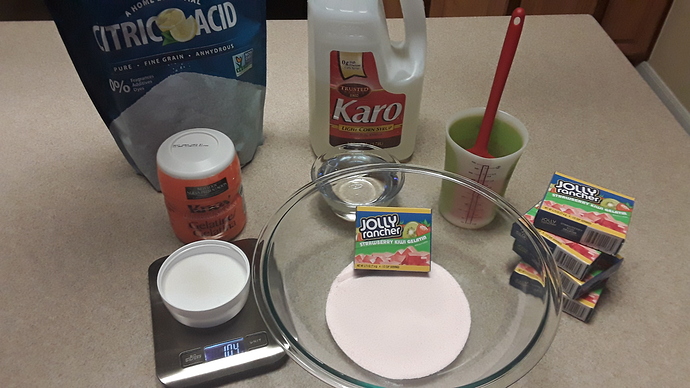

RECIPE

Dry ingredients

168 grams Gelatin

20 grams Citric acid

8 boxes of Jolly Rancher (79 grams in each package)

Wet ingredients

684 grams Corn Syrup

640 grams Water (ROOM TEMP)

40 ml of Propylene glycol

5 ml of Lorann Mold inhibitor

##.## grams of your target cannabinoid (2ed post will explain dosing calculations)

This makes 1200 small bears (for me).

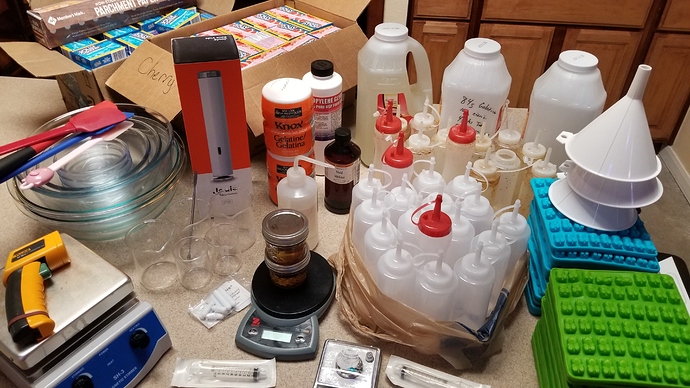

Gather all necessary equipment and ingredients.

Wash all the dishes and molds to be used.

FYI…Washing will be your last step to…

As you wash the glassware to be used. Take note of the glass condition. Any broken or chipped glassware is to be discarded immediately. It sucks to find out during cleanup there is chipped glass and you DONT KNOW WHERE it’s hiding!

Rinse off molds. Cover the counter with a towel, beat each mold a few times on the towel. Put molds on a cookie sheet and place in oven. Set oven to around 300-350 F. Take out after molds are dry, 5-10 min. I have forgotten and left them in for over 45 min, no biggie (with my molds).

In the above Photo, you will notice that I have ALL ingredients weighed out for ALL of the flavors to be made. We have two people at work here. One is weighing all the dry ingredients and the other is weighing the wet ingredients. The KEY here is that the two workers VERIFY each others weights! (crucial step is to verify every-time)

Add all dry ingredients together as photo above. Mix dry ingredients together evenly with spatula or spoon (not shown).

Add the corn syrup before adding the ROOM TEMPERATURE water. Mix with a spatula, mushing the clumps to the walls of the bowl. Make sure there are no clumps stuck to the bottom of the bowl. There is no need to go to town with the spatula, just make sure NO BIG CLUMPS and no clumps stuck to the BOTTOM.

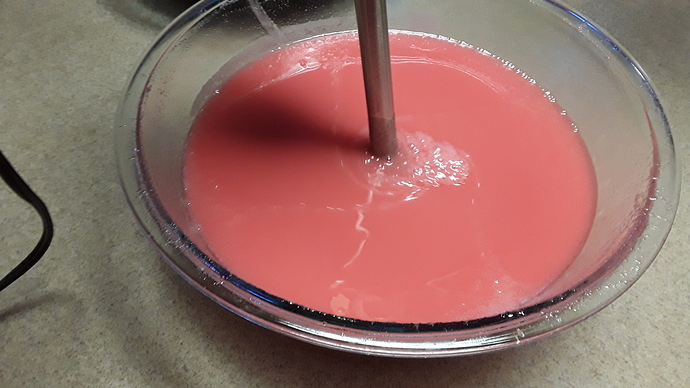

Pull out the stick blender, and go to town. You will use the blender longer in this step, than is required for the cannabinoids being mixed. It takes me 3 minutes with the blender at this stage. Have hot water waiting, after mixing, wash off blender immediately (will save you a bunch of time).

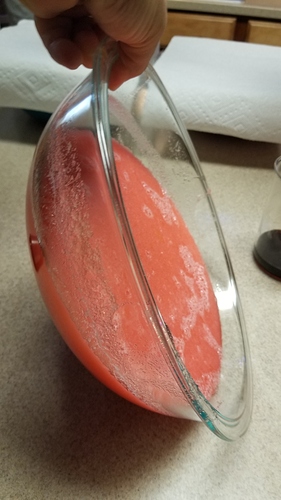

Let the gelatin mix bloom for at least 20 minutes room temp on the counter. You can let the gelatin set for hours on the counter.

This is what my first batch looks like when it is bloomed.

This one set for a few hours before I got around to it. This one will require longer in the microwave as compared to the first one I mix up.

After bloomed, place bowl in microwave for 1 min. Remove bowl and stir with spatula. What you are doing here is dispersing the heat evenly in the bowl. Back in the microwave for another 1 min burst. Keep repeating these two steps until the batter reaches 120 F.

1 Min in my microwave equates to a 12 degrees rise in temperature.

WARNING

Learn your microwave first. Your microwave may be more powerful, or your using a different type of bowl, or perhaps 1/2 size recipe.

I also prepare all of my beakers in the beginning with 40 ml of PG and the target cannabinoid. Mixing with a hotplate/stir bar. Target temp for PG is 120 F, everything seems to mix well at that temp (for me).

Right before you add the beaker of PG and cannabinoids into the bowl, give it another spin on the magnetic bar.

Dump in the PG and Lorann Mold inhibitor (potassium sorbate) . Try not to dump PG in the center of the bowl, like the pic above. The stick blender tends to get coated with the PG, if you put it right in the oil slick.

This is a better example. Also angle the blender skimming the top, so that it sucks in the dark oil slick. The reasons I use PG are, it mixes better into gelatin vs MCT oil and You can easily visualize it mixing into the gelatin.

Mixed with stick blender for 2 min. It want hurt anything to mix it for a longer period of time.

Grab a second set of hands, spatula, 6 ketchup bottles and a funnel.

Carefully pour the batter into the six ketchup bottles.

Screw on tops and make sure the caps are on, before WASHING the bottles off. You dont want to get sticky in your sous vide.

Place in 120 F hot water bath, warmed by a sous vide. These can stay in the hot bath for over an hour, but it only takes a few minutes to squeeze them into their molds.

Tip Notice what I have circled. If you dont use this bottle first, you will have to switch out tops. Because it will be clogged and you dont want to squeeze on the bottles that hard.

I have had a few tops pop off before.

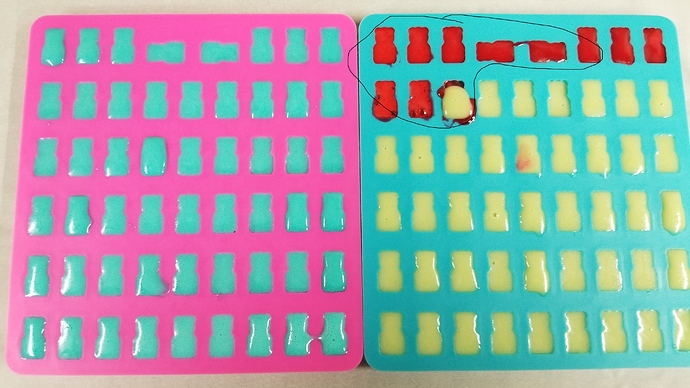

Squeeze into the molds. Notice what I have circled, this is the end of the bottle, and the wook is in a hurry. The last few bears will have bubbles if your wook has no patience (or they know the get to keep the ugly ones).

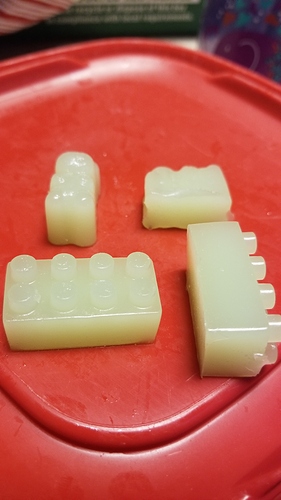

If you take your time on the last few gummies. They will look like this. Hold the ketchup bottle straight up and softly and slowly squeeze. NO AIR.

Put the molds up so they are protected. Bag them up when no longer Tacky.

My target environment is 45% humidity, if the humidity is higher it will take longer to become non tacky. The temperature is not as important as the humidity, but <80 F is preferred. At 45% it will take 1 day for them to be ready.

@Dr.stanky He suggested using a refrigerator at this point, I shot him down. He was right and I was wrong. A refrigerator works just fine. You dont want to use a freezer, as it will leave a frost coating. That will turn into a wet coating, when dried they will be very tacky. However you can freeze gummies for a long time if need.

These are the brands we use.

If all the steps are done in a clean environment, you should get at least an 8 month shelf life. ![]()