FOUND IT!!! Question about Wiped Film performance(what's real and what's hype) - #14 by drPaul

My two cents, dow corning is absolutely garbage. It’s used for lowntemp work like distilling water if your lucky bro not have it contaminate your batch.

Apiezon 501 or h are the two go to ones. Also a cheaper but effective one is kluber.

Crappier grease means less ultimate vacuum bc combined leaks prevent performance ratings.

dammnnn… that looks nasty

A photo tribute to always dewax and polish your crude before starting any kind of spd or wfe.

Your 2 cents are super expensive lol… that Apiezon is crazy expensive or maybe it seems that way because I convert that to pesos and its overwhelming, ill go with the Kluber option and after I cash in from my first disty run ill get that royal vac grease… thanks for the tip king

Really ?? Also polish ?? like with activated carbon, celite, bentonite and the whole shebang ??? I thought I would only winterize my crude and start distilling afterwards

Well, as with making any other drug; The more pure and clean with any starting chemical mixture, the more clean and pure the end result. Shit in, shit out

I like reading into illegal chemical synthesis. LSD requires a chemist to make the starting chemical mixture as pure as humanly and scientifically possible before they start going down the process of synthesis.

I would never make LSD but the process intrigues me

Those should all help.

Edit : I forgot this, The Pepsi challenge/etho color remediation thread

Never say never, if you ever need an assistant you know where to reach me, I just took a couple hits of LSD while I was infected with the rona and I swear to you that it could be the perfect medicine for covid, it made me feel so good like you have no idea and I was having a shitty rona day feeling a bit sick, and I remembered LSD improves your overall oxygenation and that’s exactly where the rona hits you the most, your bodys oxygen level drops, so I took some LSD because I felt the oxygen thing was a big enough excuse to do it and it worked like a charm.

So anyway you wanna make some anti rona medicine hmu lol !!!

Thanks for the links btw, I will definitely do a dive deep into those threads

You use very little at a time. It spreads out to like 50 cents a run or a dollar at best. Also kluber isn’t very expensive. It’s less than apiezon but overall you use alot less with these greases than you’d ever use with dow corning. Also the cleaner your input is the lower your vac will be and the better it will run. The dirtier your batch is the limited result will apply to the end product.

I just wouldn’t attempt it. It sounds easy but there’s such a difference between extraction and chemical synthesis. The fact you need to farm rye and hope some gets infected with one of the most dangerous to be handled spores/mushrooms out there. … … Dark rooms, lighting differences, oxygen levels, respiratory suits and fume hoods.

Im good on that shit.

Not to mention it’s highly illegal and if you fuck up, its not like dabs where you can just say fuck it and dab poop soup and feel like you can go on with your life saying whatever; If you fuck up making LSD you could potentially die, burn down your house, knock yourself out with a chemical fume, inhale dangerous ass spores by accident. … I’m not willing to take those risks.

I also think the feds look out for people who buy precursors.

Generally it seems the major clean up works best between 1st and 2nd pass because there is some stuff made during the initial distillation that can be cleaned out. Water washing in particular is very useful.

I do agree with @spdking that the dow grease is crap but it will work. I haven’t had the pleasure of using kluber so maybe that’s the better value proposition

One of my favorite process runs is .

Extract.

Ethyl solute.

Winterize.

Carbon scrub.

Evap.

First pass

Water washes.

(Optional chroma for remediation)

Second pass.

I find this tried and true method resolves hella issues with Distillation up from for people learning. And it makes high potency shit too.

Agreed. I prefer methyl winterization but I agree, water washes and chromatography belong between pass 1 and 2. Water wash is pretty much necessary after column anyways to neutralize. Only downside is the effort of redissolving and also making sure no heptane contaminates pump oil

Another cold trap?

Many ways to slice that cake. Best option is to use a separate pump and trap to rough down because remember, even with a dry ice trap, once you start hitting the submicron level you’re still way above the boiling point of the heptane at -86c. Even with LN2 you’re really not going to be able to keep solvents trapped the way you want for a second pass. Better to get it all out on a separate pump and trap so there is nothing volatile to compromise your vac level during the mains.

Other option is to just empty/clean the trap and change oil. Another option is to be super thorough removing the solvent outside of the still before second pass.

Personally because we have a monster pump that does like 400cfm and is dry so there’s no oil to contaminate, we just make sure to pull the solvent out before opening the diff pump up to the system. Once most of the solvent is distilled, I honestly just let it rip through the pump and heat gun all the piping/traps to bake out any condensed volatiles. Once I hit 80-90C at around 500 micron for a good 20-30 minutes I actually fill the traps with dry ice/LN2 and fire up the diff pump. Kind of a weird way to run, I would recommend it on any kind of wet pump

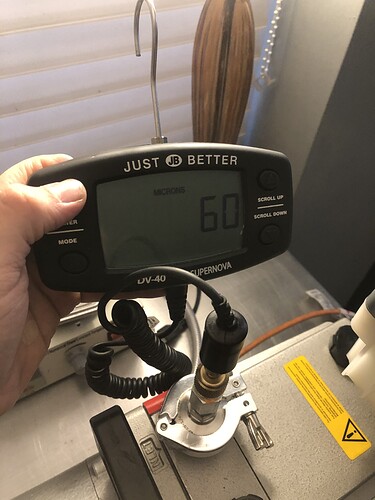

Im testing the pump I got before I start my first spd run, I just put fresh oil in and put the vac gauge directly in the pump and it will only pull around 2800 microns like the picture shows, any ideas on what could be wrong ?

Those adapters could be leaking. Is that thread tape applied correctly?

Even with the threads leaking, it should pull sub 1 torr I’d think. It’d have to be a fitting mismatch or something. How’s the oil? Changed recently?