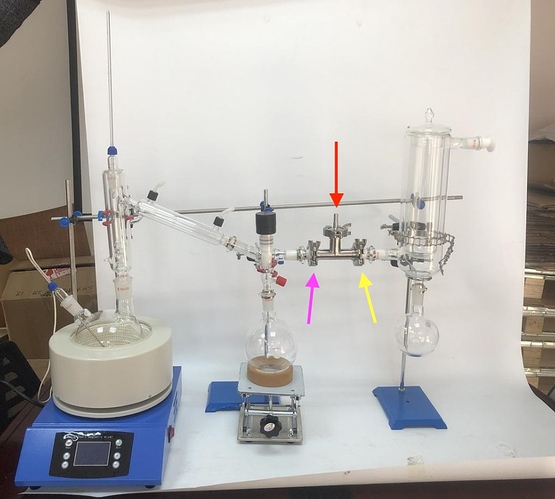

Im adjusting all the details on my SPD system but I ran into a wall trying to figure out where to place the vacuum gauge at since im shooting for a full bore setup im really not sure where to place it, I was thinking maybe where the RED arrow is but something tells me it will have to go either where the PINK or YELLOW arrows are because I gotta feeling that it has to flow through in order to get a read on vacuum and the red arrow port won’t work cause of that, but I could be wrong, so below that pic with the arrows is the vacuum gauge im trying to use, any help anyone is willing to give is greatly appreciated

Exactly at the red arrow pointing down.

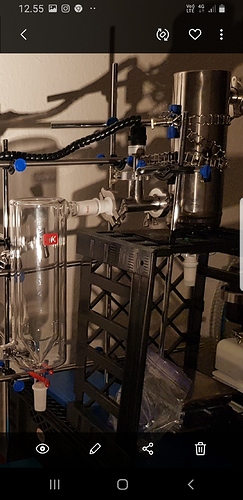

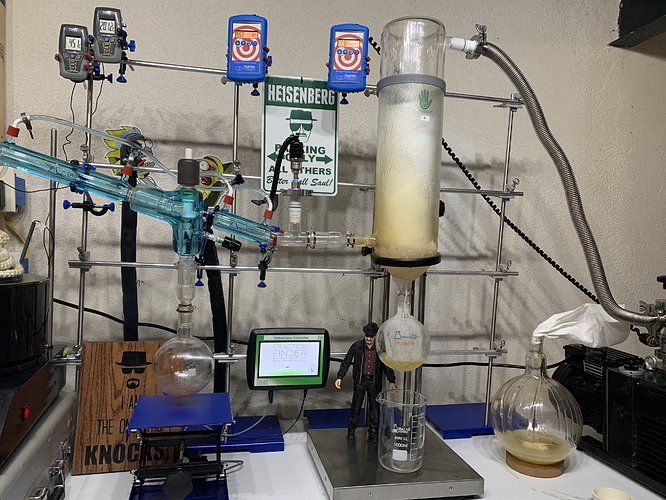

I’ve posted many pics of my setup, as well as other. Try emulating how we had ours.

You do not need flow through to read vacuum. Placement between the cold trap and pump will keep your gauge happier (cleaner) but the reading will be artificially low. Placement where you showed will be the other way around and is the more common placement. Many run both

@SidViscous

Actually I agree. After CT is best.

im actually placing 2 cold traps on my system, so then what you are saying is that the best place to place it would be between the pump and the first CT correct ?? Also what do you think of that vac gauge im trying to get, think it’ll do the trick ?

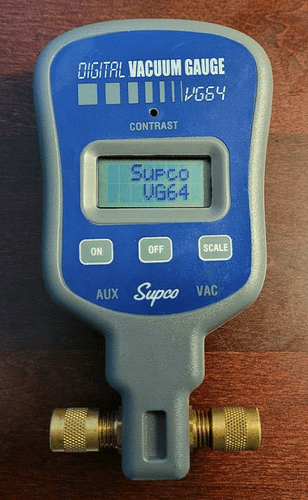

I’m not familiar with that particular gauge but it looks similar to the testo HVAC gauges. They’re not super accurate but they will let you know if you have a leak and if you have a vaguely appropriate level of vacuum.

Also I wanted to mention that even though those vacuum gauges allow flow through them, you definitely want to tee off your main vacuum line because otherwise you will seriously restrict the flow path and not be able to vacuum down well/quickly.

Between pump and trap is a good place although again, you have to be patient with your temp increase because the vacuum will lag in the boiling flask a bit. Alternately on the other side you’ll see more accurate vacuum but might gunk your gauge up a bit. They are cleanable as long as you’d don’t let them get crusted up for too long

In that case what I would do is place a 3 way connector with the gauge on top between the pump and the first cold trap so I wont restrict flow at all, what sort of gauge do you use ?

Yep, that layout should work well.

I use a bunch of different gauges for a bunch of different things and honestly we don’t do too much distillation. I use a lot of MKS 901p transducers which are available pretty inexpensively (~$70 off eBay) but the controllers can be expensive ($400). Fortunately there’s an open source controller solution around here somewhere. Also, I’m working on the programming for a siemens logo but haven’t gotten a chance to finish it, so that should drop the controller price to around $100 with minimal DIY. I’ll post it here for everyone when I’m done.

Lastly, bullseye vac gauges are probably the most ubiquitous gauge for distillation so you might look there.

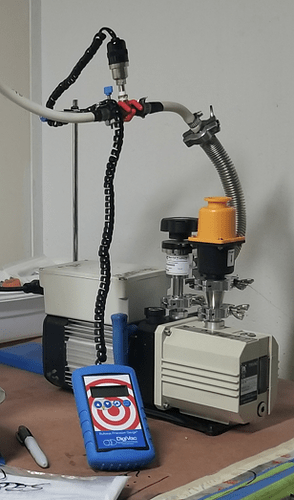

If you only own one guage you want it at the pump. Putting it on the side will tell you nothing but a fluctuating value vs the pump will deliver ultimate vacuum readings. Wich will be it’s performance.

Using two gauges. One at spd and one at pump is only for the delta or varriance reading. However it’s only usefull of you have two gauges.

Always put your gauge at the pump if you only have one. This will tell you spd performances and pump life indicators.

Hey what’s up man, I talked to Nieko yesterday he was super helpful and super nice you should give him a raise ![]()

Question. When you say to put the gauge at the pump you mean just like @Demontrich has it setup ?

Blanked off at the pump. Gauge directly to a kf fitting, directly on the pump.

To test the health of the pump before running yes; obviously can’t blank off the pump while running though.

Sorry to be a pain in the ass here but I’ve spent like half an hour trying to figure out what blanked off means and had no luck lol.

So you mean I should NOT put the gauge like in your setup ?? But rather put a 3 way KF25 fitting directly at the pump and install the gauge directly on the 3 way KF25 fitting ?

Since it’s been 5 hours…

“Blanked Off” means having the pump only hooked up to the gauge… That is how you test just how deep (or your ultimate vacuum) your pump will reach.

excellent ! I finally get it now thanks !

So beautiful, love the decoration ![]()

@Demontrich @Capttripppp @HeisenbergInd @SidViscous @spdking I gotta question for yall (tryna sound Texan ![]() )… I need to know if an Edwards E2M8 would work on my 2L SPD setup

)… I need to know if an Edwards E2M8 would work on my 2L SPD setup