Just going to put this right here and see if anyone learns something and maybe catches up… without causing too many trolls to come out of the woodworks…

Ethanol extraction of d9 containing trim

Done at -40C

Passed through bag filter then lenticular

Solvent was removed using falling film/roto

Material was decarbed on a spd under vac. Bf was brough to 140C then allowed to cool to 100C with stir and vac on.

Placed in the hopper of a wiper. Distilled at 170C/100C at a vac depth of 200 micron in the system next to the column… before the cold trap.

Material was diluted with heptane

Heptane solution was 1:1 with product.

Brine was mixed at a ratio of 20lbs to 20gal of ro water

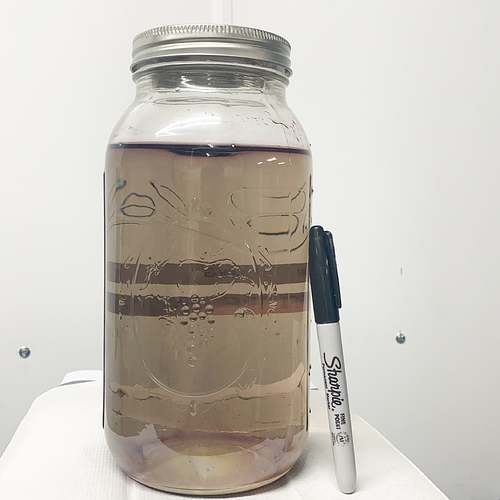

1:1 ratio of heptane solution with brine was mixed vigorously in a glass reactor. 2 table spoons of citric acid were added. This brought the pH to around 4-5

Mix lasted for 5 minutes, after separation, water layer was removed and discarded… this was repeated 4 more times

Again brine was added but during mixing sodium bicarbonate was added until saturation at 8.4 pH. If black emulsion was seen, water was drained with as much emulsion as possible and then the low pH washes were repeated another 5 times.

Once done. pH 8.4 is used until water layer is no longer pink.

One more low pH wash is done, and as much water is removed as possible. Crucial.

The heptane solution was passed over magsil at a rate of 2L product to 2.25” of length in a 6” diameter column. Gravity feed, no assist.

Immediately after being recovered from column, solution is placed in reactor, again passed against citric acid once, then twice with a neutral pH, no buffer added. All water is considered brine as prepared above.

Solution is rotod down and contents are placed in wiper hopper.

After a quick solvent strip on the wiper at 7L/hr. 166C/100C vac around 1-2 torr in the system.

Once dry, diffusion pump is kicked on and system parameters are as such.

Hopper 90C

Feed line 160C

Jacket 170C

Condenser 100C

First trap -20C

Second trap -90C

Vac depth in system next to main column before both traps. 70-90mtorr. After traps 10^-5 or 10^-6… it jumps around…

Feed rate is 6L/hr, 5L/hr is removed via distillate side. 1L or less is recirculated via residue side. Until material is scrubbed dry… all liters come out like this. Almost no residue in the end.