if youre spending $1500 on one step of your process, please spend that amount on a year of chemistry classes at local uni.

Cool bro il think about that next time

That pump will work fine. Sure it will be more hassle and a pain in the ass to deal with versus a properly spect pump but it’s still usable and if you’re cheap like me you tend to find a way to make things work. You need ewe to bleed atmosphere into your vacuum line whether it’s with a t and a ball valve or something inline so you’re able to adjust the vacuum depth you’re pulling way too much vacuum on that system and it’s bumping your feedstock

Depending on how hard you’re running that thing, I would recommend getting an aspirator like this one:

https://www.fishersci.com/shop/products/vacuum-pump-water-aspirator/nc0577126

You can find cheap used ones on ebay, I picked up a nice Japanese one a few years ago for like $120. You could also use the continuous feed and keep your boiling flask with a tiny amount of liquid in it at any given time, just barely crack the stopcock and ease it closed until it’s flowing at a quick drip (no solid stream). It’s impossible to bump over if there isn’t physically enough liquid to make it through the joint. I’m somewhat of a 2L roto virtuoso, I learned very early that you can never trust a full flask on those things, even with an aspirator with lukewarm water in it. Using continuous feed and low volumes will allow you to maximize your surface area, I can recover well over the rated liters/hour as long as my chiller can keep up.

i never even considered that someone would use it any other way than continuous feed. Wouldn’t loading the flask fully also tear out your motor more rapidly?

Wait so would I be correct in assuming since the diaphragm that runs in this unit is PTFE doesn’t that mean I wouldn’t need a cold trap at all for rotovaping ?

also next time read the whole thread at least before asking the same person the same question i already asked him ![]()

Deterministically, running a full flask vs a nearly empty flask is going to be worse for the motor, but I’ve never met someone that’s burned out a motor on a 2L. Those things are typically overbuilt, even the cheap BVV chinese ones.

well i just got my first 2L roto, so if anyone can burn out the motor itll be me

You’re sucking too hard.

Get yourself a controlled leak.

Either a needle valve, or just use the feed port as others have suggested.

Even with an aspirator, the above helps get the vac level “right”

A diaphragm pump is fine ingesting ethanol, however, it spits anything it Ingests back into the room. So a cold trap is still the right response.

I haven’t set a rotary vane pump on fire yet, but I can verify the oil is essentially swapped out for ethanol, and pump gets HOT

The auto ignition temp for ethanol is pretty high, but there are lots of other ways to achieve ignition.

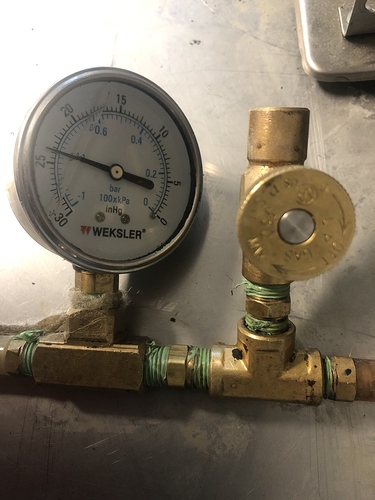

Edit: not my “leak”, but a decent implementation. Uses an LP gas needle valve.

Thanks il try that. I cant get dry ice for my cold trap all the time. Do you guys recommend any substitute? I just have about 3 gallons of etoh crude i need to do

Aspirator…

Condenser on rotovap is too restrictive to get decent flow through that AND the aspirator.

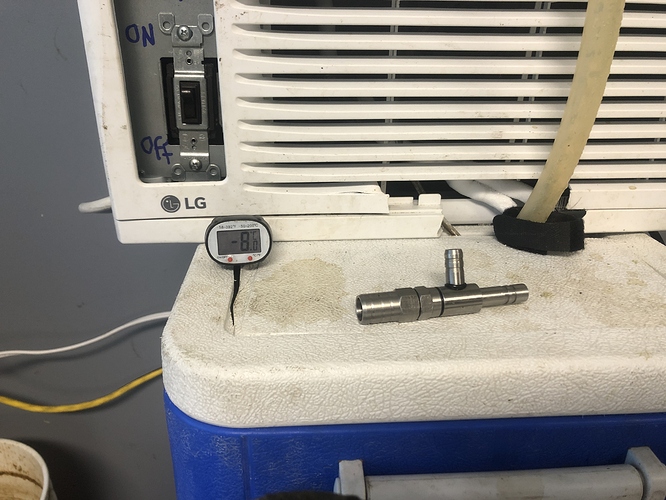

Was hoping for an AC hack that sucked…

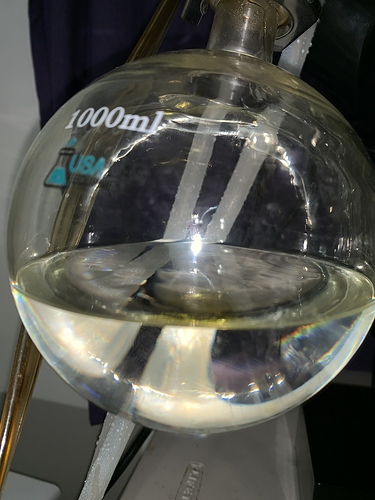

Anyone else using a bump trap?

Not sure if it’s helping…makes spraying into an almost empty evaporator pretty much impossible…

i ran my roto vap 4 times before this a no problems. but i was using a thinner hose that used to collapse basically as i turned my vac on and it didnt pull ethanol and it didnt bump. but i switched to a non collapsible hose and then the problems happened.

Check this thread as well I just got a 2L rotovap, will this vacuum pump work with it ?

Co2 tank with syphon tube. Put a sock over the end of the bottle valve opening and fill with dry ice.

Remember the four variables you control are pressure/temperature and flow/level.

Pressure increases so does temperature and vice versus. The same thing applies to flow/level.

The best thing for this process is manipulating Pressure. As stated above a needle valve is best Bc this type of valve is made for precision vapor/air flow. If you are not able to acquire this than you will need to adjust your temperature.

When i run the roto i bring up the speed to max (sometimes not applicable due to the viscosity of the mixture) and bring my temperature up to designated temp. I wait a bit till my water temps are steady go know my sloution is the same temp as my water bath. I’ll start introducing vacuum. Once i see the bubbles starting to come out i will continue vacuum for another second and wait a bit. Than keep adding vacuum once the bubbles die down

My suggestion. vacuum down and max out your rotater. Slowly work your temperatures up. Try to avoid introducing outside air in the process but def relive the vacuum if you’re over bubbling. you can bring down the speed of the rotation to slow slow down the reaction.

Second problem. Your solution is instantly bubbling Bc your introducing a liquid that isn’t close to the same temperature of what’s in your flask. Preheat the liquid for batch.

I use to run a a Buchi-220 pro

Semi found the solution and fixed my problem

i swapped out my hose for a much lighter hose (10 ft in length)

As soon i turned my vacuum on the hose collapsed making the pull much more weaker and im pretty sure it made it much harder for the ethanol to reach my pump. I turned on my pump for about 15 seconds then turned it off when i saw my etoh bubbling … it maintained a vacuum and all of my ethanol was captured into my collection flask

i didnt use a cold trap, my pump ran for maybe 3-4 times at 15second intervals through the entire process. The oil doesn’t look contaminated in my pump and it didnt run long enough to even get warm.