Hi,

I was recently contacted by a friend who wishes to enter the CBD market, has potential investors, has experience growing marijuana, and is looking at a 200 acre plot of land he happened upon. He contacted me to handle the extraction side of it.

I’m an undergraduate chemistry student, however I know next to nothing about marijuana extraction (or indeed plant matter extraction at all). I recognize that we will have to hire consultants as this is beyond my scope of knowledge. However, I would like to learn as much as I can before hiring professionals so that we can have a fluent and productive conversation.

We are looking to product CBD distillate and isolate. As I mentioned earlier, we will be growing about 200 acres of hemp. However I expect that we will begin with a pilot grow, something like 10 acres (my partner mentioned something about having to do a pilot grow to check THC concentrations for compliance purposes?)

I have been looking online for the past couple days, however most of the resources I find online are brief overviews written for laypeople. I am looking for specific for end-to-end procedures aimed towards chemists. Where can I find more in depth information on the methodology from start to finish? Preferably a book or publication?

P.S. From what I have read so far, this will be the general outline of the procedure required:

First the hemp is dried and milled. I will leave this to my partner as he has experience with this.

The biomass will then be placed into a closed-loop butane/propane extractor. As far as I understand, this seems to be the best method in terms of least post-processing. The downside being it’s harder to scale. We were looking at Precision Extraction’s multisolvent extractors (X10 or X40?) so that we may switch to ethanol if required for scaling.

The resulting crude oil contains fats that could clog up the distillation. This is removed by winterization: the oil is dissolved in ethanol, and then reduced to -70ºC or so for the wax to precipitate. This is filtered through a vacuum filter.

This oil is then fractionally distilled under vacuum. Looking at Precision’s CDU 1000 for this. At this point, ethanol should be easily removed right? Or will the quantity of ethanol be too much for the distillation apparatus, and better removed using some other method before distillation?

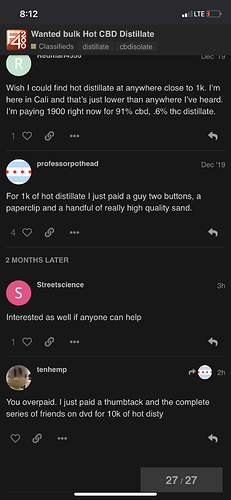

This results in distillate. We can sell this directly, or…

We can continue on to make isolate. This part is a little bit confusing to me — I have seen people say to crystalize the oil from pentane. This is a fairly simple procedure requiring minimal equipment so it’s attractive to me. However, it seems that most people use HPLC for this purpose. Thoughts?

Am I missing any big steps? Or do I have the general gist down?

Again, looking for more in depth sources. An in-depth book/article would be good.

Thanks,