You’re sucking too hard.

Get yourself a controlled leak.

Either a needle valve, or just use the feed port as others have suggested.

Even with an aspirator, the above helps get the vac level “right”

A diaphragm pump is fine ingesting ethanol, however, it spits anything it Ingests back into the room. So a cold trap is still the right response.

I haven’t set a rotary vane pump on fire yet, but I can verify the oil is essentially swapped out for ethanol, and pump gets HOT

The auto ignition temp for ethanol is pretty high, but there are lots of other ways to achieve ignition.

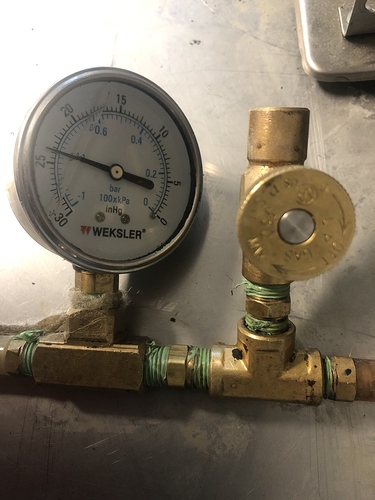

Edit: not my “leak”, but a decent implementation. Uses an LP gas needle valve.