@TheGratefulPhil

I am mainly referring to the Square-Cube Law which is a mathematical principle applied in a variety of scientific fields which describes the relationship between the volume and the surface area as a shape’s size increases or decreases.

This principle states that, “When an object undergoes a proportional increase in size, its new surface area is proportional to the square of the multiplier and its new volume is proportional to the cube of the multiplier.”

What this means is if you take a shape like a standard jacketed collection pot and double its size proportionally, the new surface area of the vessel (i.e. available area to be jacketed and heated) will be 2^2 or 4 times the original but the volume will be 2^3 or 8 times the original shape.

Do you see how that presents an issue? As you scale up a jacketed collection pot your ratio of liquid volume to heated jacket surface area gets worse and worse. Even if you increase your heating capacity to infinite kw’s, you will not be able to actually get that heat effectively into the solution to generate vapor.

I think a lot of people start with an 8" or 10" jacketed collection pot (or water bath with sous vide’s) and it works great but once they try to step up to 12" or larger they’ll notice that the heaters, even if made larger, are holding stable temperature but recovery rate has stayed that same or even gotten worse. This is because of the square-cube relationship and leads some people to conclude that skinnier collection pots create more vapor.

This leads to a conundrum in the sense that a skinnier collection pot is easier the get heat into the liquid pool using a standard heating jacket but the smaller exposed liquid surface area acts as a limiting factor to vapor generation. Once you try and step up to a wider collection pot which should in theory have more vapor production due to the larger exposed surface area of the liquid pool you hit the square-cube law and can’t as effectively get the heat where it needs to go and vapor generation suffers.

This is where internal heat exchangers come into play.

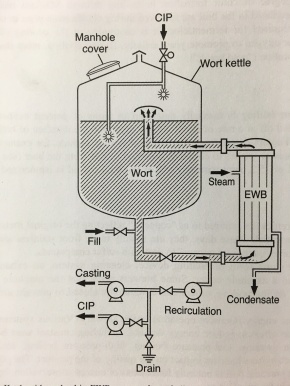

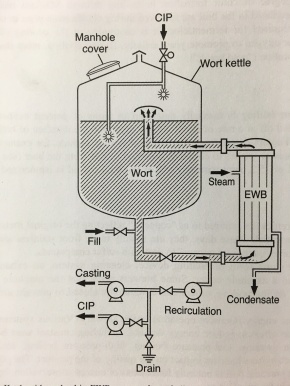

Have you ever heard of an internal calandria? They are typically used in brewing applications where they have a large, wide vessel filled with wort they need to boil. It’s basically a tube-in-shell inside the vessel.

You can also set this up as an external calandria (heat exchanger) with pumps, which is a good drop in solution that I suggested to @Roguelab to speed up vapor generation in his large jacketed vessels.

Do you see how adding a pump and external heat exchanger like the picture below increases the surface area available for heating the solution but does not significantly increase the volume of liquid that needs to be heated like with the square-cube law?

I am currently having a 24" wide collection vessel made up that has just the lower dome part jacketed, not the sidewalls. Then I have two horizontal coils that drop in from the lid and extend down to just above the height where the jacket cuts off so they’re always in contact with liquid until the heated jacket starts.

I see a lot of people currently using vertical drop in coils but the problem with that is as the liquid volume drops off there is less and less surface area of the coil in contact with the liquid and vapor generation falls off. I’m hoping the horizontal coils solve that issue.