You will never replace dry ice speed without a HUGE spend. Just ain’t gonna happen.

A DSLB-300/80 from China puts in some work for the price. Ours runs 24/5 and has not needed servicing in its first year, just general maintenance.

First time I’ve ever heard someone not say something bad about their dlsb.

Apologies for the choppy edit. Getting all of @Somepumpkins answers in the same place seemed like the thing to do at the time. But clearly coffee should have happened FIRST.

I don’t like the 80/30. The 300 rips all day. Maybe we just got lucky with whoever assembled it in China.

Only 80/300 I’ve worked with required several fixes over the 10 months or so it was my problem.

needed fixed before install. Lost a compressor and the circulation pump while in service.

I think you got lucky

I recently posted that to the Data Dump Thread. I found it very useful and came to learn that if you want to measure cold temps learn and use Kelvin measurement.

Part of the reasoning behind joining these threads…![]()

Let me try to see if I can make it simple.

Heat equals energy.

Energy in a system will always seek entropy/equilibrium, as such if you put more energy in one side of a system it will in time transfer energy/equilibrate with the other side of the system giving the system the sume energy dispersed equally throughout the system, and so what you are doing is taking energy out of one side and putting it into the other. In this case, moving energy from your butane to your fluid surrounding your coil. Refrigeration compressor works on the rule that when things expand they cool down/lose energy. Refrigeration compressors have different capacity to “soak up” energy (which is how you get the power rating). Different gases used in refrigeration cool down to a different temperature when expended (which is how you get refrigeration systems that are rated for different temperatures (but that’s not the whole story because when you want to go below a certain temperature you run into a Cascade system which is a system by which you first cool one gas that will aid in another system cooling a deferent gas to even a colder temperature)). And so now you have to figure out to what temperature you want to lower your solution that you put your coil into and then you have to figure out at what rate are you going to transfer energy into it which will tell you how much energy you have to use to soak up the heat you you are trying to dissipate.

But also there is another solution you can think about. Instead of trying to deal with all that energy at one time you can make yourself a “negative energy battery”. What I mean is get a container that is insulated well enough to where it will not exchange heat efficiently (well insulated) make it large enough and cool it over a much larger period (over night) which will enable you to use a refrigeration system with much smaller capacity.

I haven’t had my cup of coffee yet so I’m sorry if I’m sounding like an idiot. So if I’m incoherent about any of this please point it out and I’ll try to be a bit more coherent.

We ordered an extra compressor because of past issues and checked the pressure on the refrigerant (and maybe topped it off) before putting it in service. Haven’t had to replace it yet. The 100 liter reservoir minimize temperature fluctuations, which in my experience, greatly reduces the lifetime of cascading chillers. We also blow it out monthly and keep it in a cooled room. I consider it an upgrade from the Huber 390w we used before it.

1 lb of dry ice can remove about 275btu/lb as it sublimates.

With good insulation in a cool room you probably only lose about 10% of that efficiency. So you can get about 245btu/lb of dry ice.

So about 3 lb butane condensed for every 2 lb of dry ice that sublimes.

If you’re trying to condense around 300 lb of butane throughout your day you’ll need at least 200 lb a day just for condensing, then you add in things like pre-chilling and rechilling your solvent, and column recovery if you’re running it and you get closer to 300-400 depending on efficiency and speed.

Part of utilizing your dry ice efficiently is making recovery fast. Get yourself a good 3+ kw/h of heat input on a high speed pump and watch dry ice vanish as your recovery times drop; vapor path permitting.

If you only kind of understand what it takes to condense butane, you might should reconsider this hobby. Or at least do some more homework.

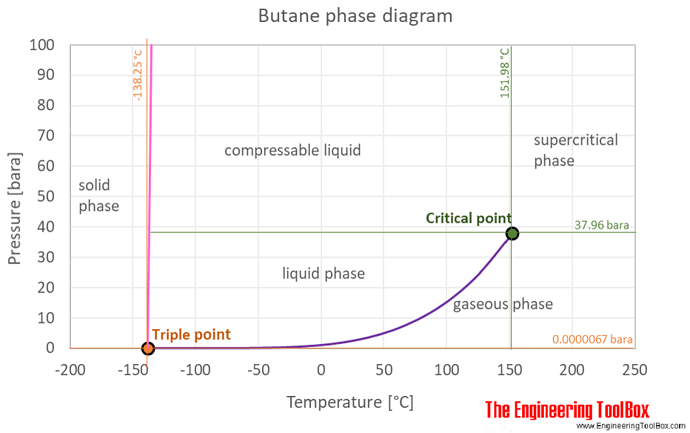

Have you run across this?

Do you understand it?

All you need is to condense your butane.

If you only have 25C water for cooling, what pressure would you need to condense your solvent?

That’s why some use pumps…

Edit: 1bar == 14.5psi

Using the same diagram, how hot does your pot need to be before the PRV (should) let go?

This critter would likely get you down into the -40C range if you insulate and are patient.

Or hit up @enjoyextra

these seem to have an appropriate amount of cooling power.

Doubt they make any sense in your world…

Didn’t read all if it but the immersion probe 1000% cannot handle recovery to any worth while degree. Tried all gases, it has no power when cold, loved it for cold traps but thats all it was good for. That and if you wanna drop the temp on a few gallons of something real quick

Crazy that you have to pay $2/w for a chiller in 120v. That 50/40 looks nice. 10kw for about $10k.

The other thing to keep in mind is electricity requirements. Anything above usually 1.5kw is going to require you hook up to 220v, like your dryer, and you’ll have to have proper wiring, and breakers, to handle whatever load you choose.

Over I think 9kw, please correct me if I’m wrong, you have to start running on 3 phase electric, which is pretty much only available to commercial clients. Like for instance that 50/40 @cyclopath posted up for you.

Just some other caveats to consider. Oh yeah, and I’ve heard they need pretty regular maintenance. ![]()

Oops!

Also if you’re looking to do something on the cheap then you should look into converting a drum or two into a chiller that would be able to handle what you’re looking to do with it a window AC unit (depending on how many BTU unit you use and how many AC unit is).

I think I seen somebody here talk about it showing pictures how he did it (pretty damn cool if you ask me)

Start here: DIY Inexpensive Chiller

Probably need to follow some of the links too

Just keep in ming… even for the diy route you will be limited by your electrical capabilities. 1.5kw is going to be the limit on 120v no matter how you come at it.