Ingredients:

Water

Glucose Syrup

Granulated Sugar(sucrose)

Baker’s sugar(for sour coating)

Pacific pectin 150 slow set(citrus, not apple)

sodium citrate

potassium sodium tartrate

isomalt(or sorbitol)

sunflower lecithin - liquid

MCT

citric acid

malic acid

flavoring(Lorann super strength for this)

food color

Supplies needed:

Stainless sugar/sauce pan

Medium whisk

Small whisk

A few small bowls

3x 3mL pipettes

candy/instant thermometer

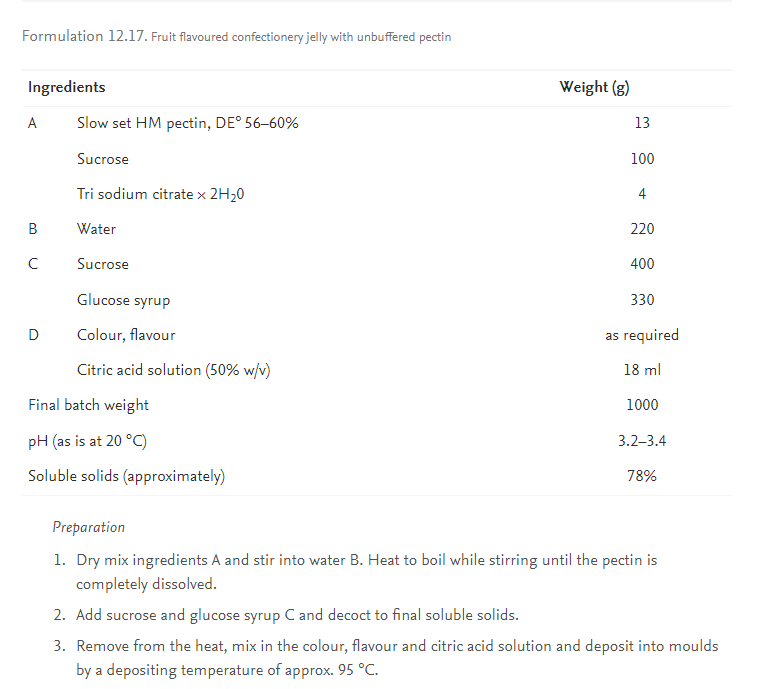

Recipe

Part A

5.2g APC-104 pectin(citrus)

1.6g Sodium Citrate

.6g Potassium Sodium Tartrate

30g Sucrose

(If using SS or ESS-150, use 4.5-12 grams, in addition to the sucrose and buffers which will still need to be added)

Part B

88g water

1.5 mL MCT

Part C

168g sucrose

2g isomalt

132g glucose

.4g sunflower lecithin

Part D

3mL Lorann SuperStrength flavor oils(or TT)

food coloring

7.2g acid mix(2.5g citric acid, 1.1g malic acid, 3.6g water)

Procedure:

Begin by gathering all ingredients (mise en place)

Combine pectin with 5-6 times it’s mass in granulated sugar and mix with small whisk. Add buffer salts

and mix(the pectin may be pre-mixed with sugar or dextrose from PP, I don’t believe the sample I got from Andre was. If that is the case, just add the buffer). Measure the additional sugar and glucose in separate containers. Add the lecithin to the glucose, I usually just stick a little glob on top.

Measure water, heat. Add MCT. Combine pectin/sugar/buffer mix by mixing slowly and allowing it to mostly dissolve in between additions. Try to avoid temperature swings from adding too much. Use a thermometer to monitor cooking temperatures.

Incorporate the glucose, lecithin and additional sugar, again avoiding adding too much and getting large temperature swings.

Bring to boil, stirring, until 222F-224F on a digital candy thermometer.

Allow to cool to ~210F. Add cannabinoids, incorporate.

Add flavoring and food color and stir in. Add citric acid and water mix, pH to 3.2-3.4

Stir vigourously to fully incorporate all ingredients and to evenly distribute acid mix, taking care to watch for gelling and working quick to get everything mixed evenly. Target depositing temp is ~203F

Pour and scrape into molds. PJ bold on Amazon makes a decent budget full pan mold, otherwise try @mgucci or @darkcitymolds . I get maybe 2-3 minutes of woking time tops, but it’s a lot easier than hm-100 was for me. I would recommend something with rounded edges over cubes/complex shapes for ease of demolding.

Allow to cool until it cleanly separates from mold, ~2 hours.

Put gummies in sour sugar mix, toss and coat.

Dry at 40-50% RH for 24hrs(I don’t have an active water meter so this isn’t perfect)

Resources:

https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/pectin

Pectins

H.-U. Endreß, S.H. Christensen, in Handbook of Hydrocolloids (Second Edition),

2009

Peter P. Greweling, The Culinary Institute of America (CIA) - Chocolates and Confections Formula, Theory, and Technique for the Artisan Confectioner-Wiley (2012)

(Food science and technology) Reginald H Walter - The Chemistry and technology of pectin-Academic Press (1991)

Modifications:

Starches and agar can be incorporated into pectin jellies/gummies with varying degrees of success. I’ve had luck with agar, although it seemed to sweat more. The starch I tried didn’t like the required temperature for pectin, but others might work.

Potassium sorbate can be added as a preservate(although the pH should do quite a bit on it’s own), I’ve used .1% of the end weight of the batch added to the water before heating.

Isomalt/sorbitol(polyols in general) aren’t necessary, I use them to inhibit crystallization/sugar crashing out of high brix candy. Playing with glucose/sugar/brix ratios can accomplish the same thing

Different acids and buffer salts(esters) can yield different results. I’ve had success with a mix of potassium sodium tatrate and sodium citrate, I’d like to play with some malate and phosphate salts as well. Malic acid and tartaric acid are also good choices for gelling, just have to adjust the amounts.

I also feel I should note, this isn’t a gold standard commercial SOP, just trying to demystify it for my fellow home-gamers.

this is the recipe I’ve based most of mine off of, from the above link. Scaled down to 450g and with a few modifications