first time poster, just found this thread. Ive been experimenting with t-5 sillica and t-41 combonations in a 4 inch column inline now for about a month and a half .

my trials have been these ratios

1:4 ratio with the sillica (always on the top stack)

4:1 for the each powder.

each trial only uses either t41 or or t5 I do not combine the two into one run.

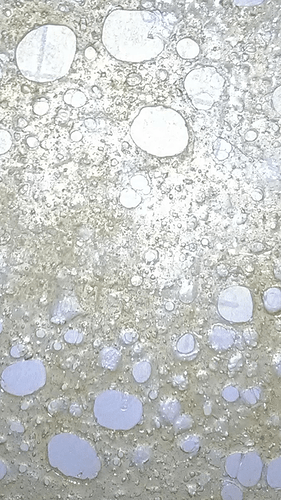

here are my findings. like many people are citing on this forumn. The sillica always feels to visibly take the brunt of the color remediation.

I have found 4:1 t41 to sillica brings me water or clear hues. I use 2 filter plates and around 60 grams total powders used or so , my runs are two to three pounds of dry material . The tields are nothing super crazy, but if you dont over filter you can get a nice sized slab .

on the oppposite ive found the t 5 highlighted more yellow hues. rather then scrubbing the colors and flavors.

I do not have a x ton press so everythiung has been hand pack with a dowel in the 4 inch filter plates like you guys.

loosely packed or channeling, will cause a weird grey gue like partially scrubbed. or no results at all. BE SURE TO PACK THAT STUFF. a little tip. I load it with a vaccum on the bottom so its always pulling the clays and sillica into place.

( ps thanks for the links to the nitrogen generators)

now here is a little gem I want to share with ALL my buddies who may or may not no why they are stuck getting sugar over and over and over again.

you will pound your head against the wall from frustrations. question your process. reevaluate and change things. and before color remediation tech, basically be making worthless brown sugar.

CHECK YOUR FUEL SUPPLIER . I had done business on a couple 100lb tanks of

keep in mind i only run 70-30

HIGH PRECISION GAS from Sante Fe springs california it comes in a large grey bottle and is sold everywhere in california supply extract shops.

DO NOT USE THIS BRAND OF FUEL.

they sell low quality fuel that is contaminated with predistilled residuals, smelling something of can of NEON from 2005. NOT to mention there is some other type of adulteration in the fuel that makes EVERYTHING SUGAR . I believe the fuel is bound to some h20 molecule .

THIS IS UNFIXABLE. YOU WILL NEVER PRODUCE A GOOD EXTRACT IF YOU HAVE A POOR FUEL SOURCE.

when i changed my fuel. every single run a produce is at my mercy to what consistency i want it.

I use GAS INNOVATIONs from La Porta,Texas. its a white 100lb bottle non odorized 70/30 mix fuel.

I believe alot of peoples consistancy woes have a lot to do with poor fuel.

but the again if they are long soaking with warmer tane, or tane thats warming up. That long process would promote sugaring and extration of whatever moisture is in your material.

TLDR, bad fuel makes sugar, silica takes out a lot of color , I prefer t41 for its ability to turn “crude into Duuuude”