shoot me a dm?

I picked up a box the other day from Walmart for a buck 50 ![]()

I don’t want to sound like a dick, but you’re just buying residual store inventory.

check the Walmart online. green apple has been out of stock for a while. Cherry is only available in store locations w/ inventory now. and the other two flavors I’m sure are depleting quickly. Walmart also only limits you to 12 boxes per flavor per order…

other suppliers have only a flavor or two avail now. and only one place has it for bulk anymore.

I can’t find it in stores, only online. Been getting the starburst jello instead.

Starbursts are made by Wrigley (Mars)

Starburst Gelatin is currently made by Jelsert, under license.

Jolly Ranchers are also made by Wrigley

Jolly Rancher Gelatin used to be made by Jelsert until recently, production is now under Kraft Heinz.

Jelsert is a grain of rice compared to the giant that is Kraft Heinz.

You’re right, my store is out of stock now. Only place I could find in stock (for a reasonable price) was some Indonesian site.

My first batch I used actual blended jolly ranchers instead of the gelatin, might be worth seeing if I could mix blended jolly ranchers with Knox and get similar results…

Hunch confirmed. The order of ingredients is identical between the starburst and jolly rancher gelatin brands.

Been tweaking this recipe…

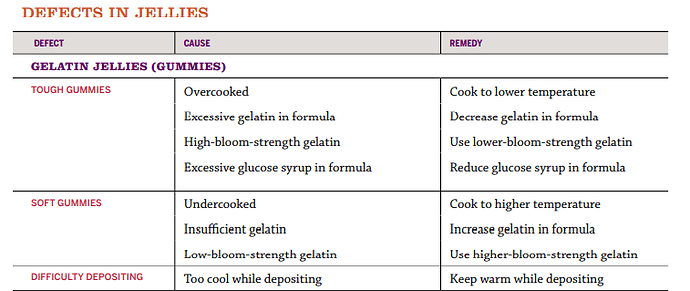

The original millerlite special is too firm after a sugar roll and cure. Also not a fan of no coating. Imo it needs wax or sugar, no dig to miller, I appreciate the jump off point.

Anyways here is the ingredients for 1 box at a time

79g (1 box) of jello

18g gelatin (beef (Knox) is fine, but

have been playing with fish derived lately)

10g sorbitol

2.5g citric acid

86g karo

66g water

~1ml of mold inhibitor

Follow sop as directed above. Bring to 130f instead 120. I prefer pour and scrape over bottles.

After demold, sugar(and malic acid) roll and set on racks for 24-48 hrs so that they do not sweat when bagged

personally, I say learn pectin. Miller sent me some unmedicated samples and he’s definitely improved over the original recipe though

No digg taken… lol

This was supposed to be a starting point for the DIY dude…

We have literally made hundreds of variations (without using boxed brands) of this recipe… and asked for feedback… surprisingly, not everybody’s opinion is the same… there does appear to be a happy medium… but there is a wide variety of opinions of what is the most appealing texture…

We have come to the conclusion… Each cat to their own rat… meaning… Everyone is different in there opinions…

The recipe we have on the store shelves… is a recipe I will never share… sorry…

However, we plan to offer something this forum has never been offered in the past… shortly…

Just need a tad bit more time to get our SOP nailed down… we are asking a lot from it…

I can only deliver to local stores using gelatin…

I can ship world wide using pectin…

In the Texas summer

I got scared of the box supply going dry with the manufacturer change. Bought the slushy concentrate and started to rnd a recipe with that too ![]()

Biggest thing was finding a flavor house I liked. And I think I found one finally.

Lorann seemed hit or miss to me. Their peach is very good, but their green apple misses the mark (for me, at least).

I’m very much on it. Once, again flavor house thing was the barrier from production size batches.

I’ve been very impressed by gummies that use both pectin and gelatin. For anyone reading this the particular gummies are “…dialed in gummies” on the CO rec market.

pectin and gelatin combos are weird, gelatin doesn’t like to set right at low pH

I’ve had success with pectin and agar, pectin and modified starch seems doable if you stage the process right

Did you buy an sop from another forum member here?

For the combination recipe? No I haven’t. It was simply a formulation that completely stood out texture-wise in the wild

Haven’t bought any SOPs pectin or gelatin either.

That’s very similar to what I’ve been experimenting with. I found that 130-140 is the sweet spot, anything above 140 and the gummies are just way too soft. I let my gummies dry on racks for a bit before coating with 3 parts sugar to 1 part citric acid, then let dry on racks again bc they’ll get all sweaty, then coat with sugar. They’ve been doing fine in my jars. My main issue was a strong bitter aftertaste with higher doses. Some of my clients actually prefer the bitter ones since they see “5mg gummy” and their weed ego is offended. I want to make actual good tasting products, so they get the sugary cereal bars to mask all the good stuff to put them on their ass. I was looking into bitter blockers for a bit, but it seems very high scale. None of the companies I reached out to wrote back.

I’ve been thinking about using sorbitol, what would you say the biggest difference in the end product is? Also do you think that using malic acid as opposed to citric would help with the sweatiness? These puppies were drying for forever.

I need to level up to pectin eventually, baby steps for now. Thanks again @MillerliteRN for helping out the little guys.

Texture is totally different after the extended cure, just try it. More like a commercial gummy.

It’s the citric acid doing it more so than the sugar ime.

It’s extremely hygroscopic in it’s anhydrous form

I keep wanting to post in this thread because its gummies.

i miss you <3

For the guys running pectin, which pH meter are you using at the high temps? My blue lab meter can’t take reliable readings at 200F!

I bought a mettler Toledo easy 5, it’s rated up to 105° C

Whether the eBay seller follows through or not is another matter