Respectfully, you are incorrect dear sir.

I dont have the time/energy to respond to your entire post.

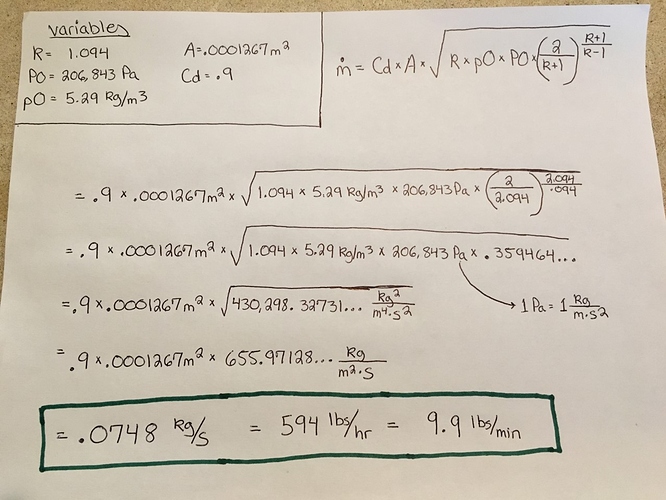

Please review my underlying calculations if you wish, specifically:

https://www.instagram.com/p/B4ZTOKch4Vl/

Which uses formula for Mdot found here:

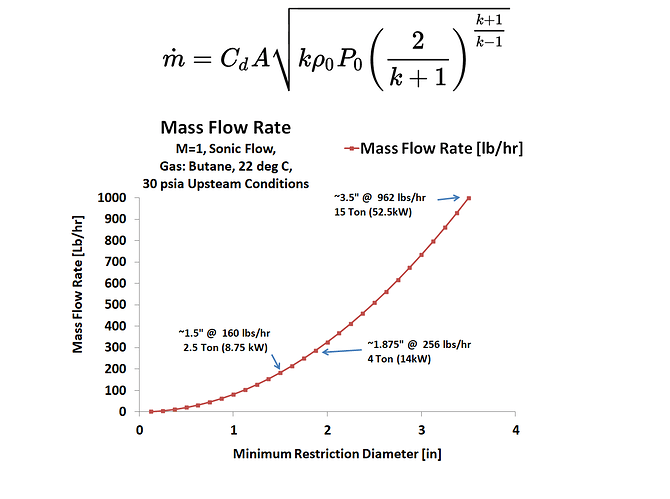

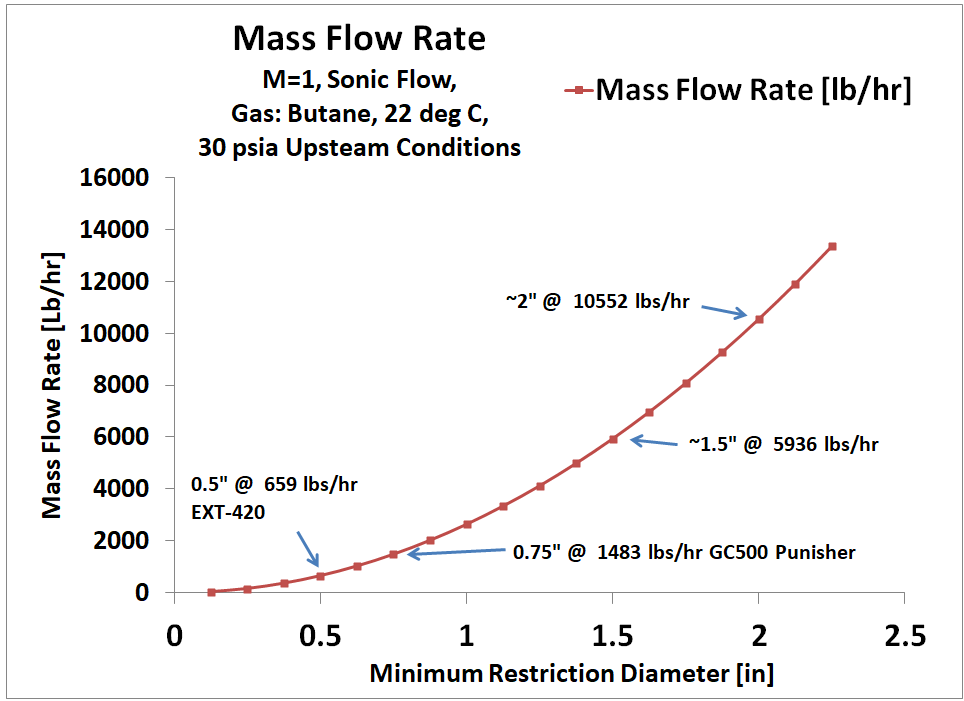

I maintain that most if not all extractors passive or active experience flow choking.

Review the numbers below, tell me if you can find fault with them:

Nomenclature:

Mdot = Mass flow rate [g/s]

M = Mach Number [Dimensionless]

γ = Ratio of specific heats [Dimensionless]

P = Pressure [Pa]

Rho = Density [kg/m^3]

u = Speed of gas in the pipe [m/s]

c = Sound speed of the gas [m/s]

Cd = Coefficient of Discharge [Dimensionless]

Cv = Flow Coefficient [Dimensionless]

A = Orifice cross sectional area [m^2]

k = (1.094) Butane, Propane (1.13),

Example Pressure P0 = 206,843 [Pa] (30 psia)

Example Density ρ = 5.29 kg/m^3 (5.29 g/L)

Example Area (for 0.5” Dia) orifice A = 0.0001267 m^2

Example Cd for smooth surface Cd = 1 (ideal, typical values 0.8-0.9)

I understand your point about confirmation bias, and yes at smaller scale a pump may be more expedient, however analytically speaking I have not found a valid counterargument to my analysis in your post.

Respectfully,