Rather than address every thread one by one, I wish to address this discussion with its own thread and provide some academically grounded insight.

Introduction:

Active vs. passive recovery is analogous to the concepts of CNG vs. LNG when discussing natural gas. CNG, which uses pump compression, has a smaller capital cost which makes it suitable for small/mid scale applications. Whereas LNG (liquefied natural gas) dominates at very large to medium scale, and can be stored in very large low pressure cryo tanks, rather than CNG tanks which become impractically thick at large scale.

A similar issue can be seen with butane/propane extraction, at small scales the speed provided by a vapor recovery pump vs. capital investment is favorable, esp. for old school setups involving TR21’s and steel (rusting) butane tanks. However as the scale increases it becomes problematic for a number of reasons, the first of which is grounded in some basic and universally accepted physics.

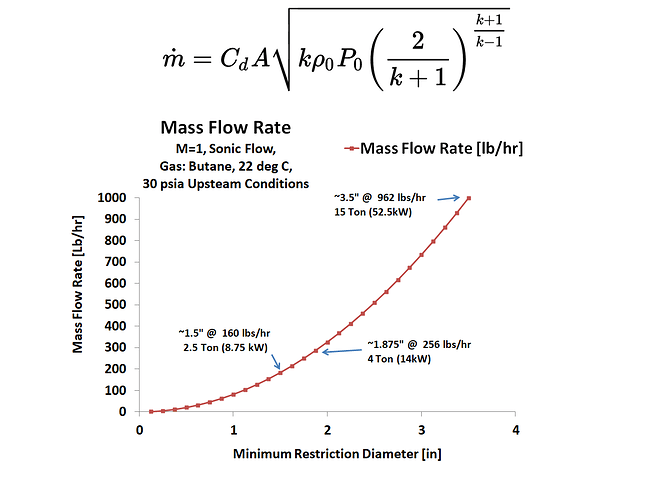

Enter Choked Flow Theory: (Choked flow - Wikipedia)

Summarizing, in a gas flow situation the fluid is compressible and in situations where flow is forced through an orifice once the downstream pressure (p2) (after the orifice, such as at the inlet of the recovery pump) drops below roughly 50% of the upstream pressure (p1) the flow will “choke”. What this means is that a shockwave forms in the orifice, which limits the ability of gas molecules on the downstream side of the orifice to communicate with the upstream side, thusly decoupling the downstream pressure (Now at P2 < ~50% P1) from the upstream pressure. Once the mass flow rate reaches the point at which choking occurs, no further amount of pumping speed will affect the flow rate!!! The pump is maxed out and it can’t pump any harder.

For the given upstream pressure and temp (P1 & T1) no force in the universe can increase the mass flow rate once the choke point is reached.

Counter points:

- Ahahh you say!I will pre-cool the butane prior to the choke point, thereby increasing the density and subsequent mass flow rate! Yes this is possible and valid (Density increase due to temp decrease), but really just illustrates my entire point, pre-cooling the gas requires a cooling system or at least water tower/evaporator to provide heat rejection. You could just provide more cooling, and liquefy the butane and have a much simpler extractor flow diagram. Adding yet more lines, and yet more intercoolers creates a rats nest of extra bullshit.

- Or you could say, I will use propane to boost the pressure P2! This is also possible but really doesn’t address the core issue and 100% butane has been shown to be a better solvent for quality and yield.

Further discussion points/assertions:

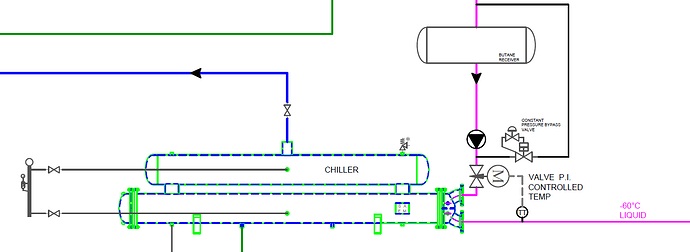

- Passive systems which provide a large enough un-restricted orifice between the recovery pot and condenser and enough refrigeration power are much simpler and less complex on the extractor side.

- Choked flow only refers to the idealized case of a flat plate with an orifice in the center, most extractors include fluid lines to connect the tanks and pumps, the more pumps and intercoolers are required the more lines must be used which creates additional flow loss via frictional (Friction loss - Wikipedia) pressure loss which I have not even included for the purpose of this simplified analysis.

- Using liquid CO2 or LN2 is incredibly inefficient and costly, even at the bulk rate of $0.5 per gallon and commercial power cost of 7.68 Cents / KwH on the basis of operating cost alone.

- Other analysis I have seen points to roughly 1 gallon of LN2 being required to chill 2 gal of ethanol to -40 Deg from 30 Deg C

- On the basis of operating cost alone electric refrigeration is ~8 times more efficient based on preliminary analysis of our systems, and reaches lower temps in some models (-48, -60 Deg C).

- Including CAPEX and waste heat to determine the payoff point for the refrigeration system vs. LN2 indicates the quickest payoff point would be reached with our 15 ton Piston system in as little as 4 months. (granted this is complex analysis and has many underlying assumptions, systems that are configured differently have higher CAPEX and payoff occurs within 6-12 months)

- Refrigeration systems (such as those offered by GPS LLC) can be configured to recover their waste heat and route it back into the process, producing significant additional energy savings.

- A passive extractor with a large near direct connection between the recovery pot/FFE and butane condenser is the ideal solution, simpler and safer to operate.

- No electrical pump is required in the C1D1 Space, reducing noise and hazards, only a means of transferring the glycol/refrigerant from the external refrigeration unit into the C1D1 space is required.

- Removing the recovery pump removes the need for air compressors and associated noise inside and outside the extraction space

- Some(all?) pumps are dirty and shed Teflon and metal shavings into the oil (TR21)

Final assertion:

Once the total capital, ownership and operating costs are taken into account, passive electrical refrigeration is by far the safest, cleanest and most efficient method, far beyond LCO2, LN2, pneumatic or electrical pumping in anything beyond small scale applications. With financing available to get over the initial investment there is no rational reason(beyond refrigeration system production/installation lead times) to use the other methods with higher operating costs, when that time and money could be spent paying of the electrical system and reaching the breakeven point within 4 months to a year(depending on configuration).

Only by an overly narrow analysis of extractor/pump cost and operating costs can butane pumps be viewed as an appealing option by parties likely lacking the right information without considering the overall processing system as a whole.

(End rant)

(I understand my analysis is shooting from the hip here, but if anyone wants to split hairs and do more calculations you will not find huge differences)

(I am working on a longer white paper on this, if anyone wants to see my underling analysis and spreadsheets DM me)