I truly think I offer the best membrane skids on the market currently, in terms of hardware quality, engineering, energy use, automation, etc.

However, not everyone needs a fancy peer reviewed skid. Some people operate DIY everything. I’ve been there many times in my life. Many times I had to come up with a solution without a lot of money, and I didn’t care about peer reviews. So for everyone in the DIY mode, here is a guide to making a simplified membrane system without a lot of money, featuring detailed analysis of one such system I actually made and used myself for r&d.

Though I may even be cutting into my own business by posting this info, my hope is it will pay off because the more people doing their own membrane R&D, better and better membrane solutions will be identified, and that benefits everyone in the end, as long as it’s being open-sourced!

Here is a picture of the overall system:

So you can see, the order goes as follows. First, the feed pump draws solution out of a drum. Then the feed pump outputs that through a pressure gauge and flow meter into a housing. The housing has two outputs, the retentate and the permeate. The permeate goes into a new drum. The retentate then goes to an adjustable pressure relief valve, which controls the system pressure. Then the de-pressurized retentate goes through a heat exchanger to remove waste heat, and finally, it goes back into the source drum.

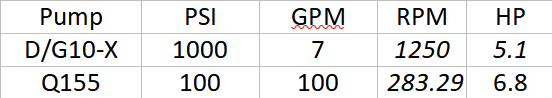

The pump I use here is the Hydracell D10, which can go up to about 9 gpm and 1500 psi (not that i’m running it that high). I like it a lot, the flow is pretty pulseless and the manufacturer unambiguously certifies it for solvent use. I got this for ~4k. Ethos and KOTK both use CAT pumps, I think they maybe a little cheaper but not by much. When I wrote to CAT pumps they wouldn’t declare it safe for solvents. Probably, it is fine. Another pump I’ve been interested in but haven’t tried is Danfoss.

I got this housing from China, and the quality is really good. The end caps clamp easily and it holds up to 1000 psi no problem at all. The O-rings it came with were silicone but I replace them with Viton. This cost about $400 and I can source them for people if they want. Tri-Clamp and Swagelok are both available, as well as bare tube if you want to do something different.

I’m running one housing here, but you can daisy-chain them for fairly linear growth in rates. Up to 4, probably up to 8 without appreciable problems, at least when running high pressure solvent recovery. I run winterization at a lower pressure and there you might run into problems stretching it so far. You lose about 15 psi per housing from start to finish.

I got this PRV from McMaster-Carr, and it is limited to 700 psi so that’s the hard limit on this particular system. They made a 1200 psi one which I wish I had got instead, but most of the membranes I use are rated to 600 psi so it didn’t really matter. You can see the flow meter, also from McMaster-Carr on there.

A heat exchanger is necessary, one because the pump generates waste heat, and also because the temperature of the fluid controls features of the permeation and this can be intentionally manipulated. I got this heat exchanger off amazon for $100. It’s only rated to 450 psi, so I put it after the PRV – what i’d really like to do is run it directly after the pump before the membrane. StandardXchange makes quite affordable 1000 psi heat exchangers. That’s what I use on my X-Spirals and you can get one for less than $1000 certainly.

So then we get to the membranes myself. In the old days nobody wanted to touch this application besides Evonik and they were expensive AF. That is no longer the case. Here is a very incomplete list of some much cheaper vendors who sell ethanol compatible membranes:

Synder (I use these most of the time)

Dupont (Ethos uses these)

Alfa Laval (come in wonky sizes slightly too large for standard housings)

Microdyne-Nadir

Koch

Permionics

There’s a lot more out there and there’s no reason for us to be hiding our selections at this point. Some companies made a killing by identifying cheap membranes, refusing to tell their clients what they were, taking the labels off and reselling for 10x the price. If you buy a skid and the person won’t tell you what brand of membranes you’re getting, it’s a sure sign they are pulling this maneuver! All of these are under $1000 per 2540, and most are under $500.

When you want to try a membrane, read the membrane data sheet – it should identify a maximum pressure and a recommended crossflow. Make sure you can deliver the recommended crossflow and preferably a little more on top, because we are running some very gunky materials here compared to the typical desalination application.