At Ethos we have primarily used CAT pumps for smaller applications. However, for flows above 20 GPM, we recommend centrifugal pumps, such as the sunflo series of multi-stage centrifugal pumps. If you wanted to automate a mini system while batch-processing, we could do it without a pump. A tank of inert gas will work if you can monitor the flow of your concentrate accurately.

If you want to discuss the pros and cons of different commercial systems, that’s a good topic, but this is about DIY systems… Anyone is welcome to contribute info to that.

Just to set the record straight, my 4, which is an actual existing unit with crossflow 53 gpm, has an FLA of 21 amps. I’ll leave it to the reader to tease out who’s math is closer.

How many volts?

53 gpm x 600psi / 1460 = 21.70 hp

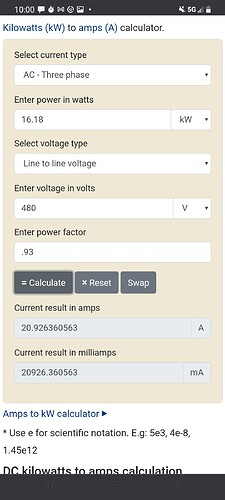

21.7 hp to kw is 16.18169 kw

16.18 kw 3 phase with a power factor of .93 would give you 21 amps

My calculations are good bro

This also points out how inefficient 2 motors is

.7% power factor loss x 2 means you have twice the inefficiency (power factor is efficiency essentially)

Mmmm I think you might be missing something though. You multiply that power factor (and efficiency) times the shaft power. Whether that’s 2x10hp or 1x20, if they’re both .93 PF then it’s the same result. What you’re arguing is that a larger single pump is more efficient than two smaller ones which, while true, I think is missing the point slightly. And in the scheme of 25hp probably less consequential than the motor temp

I’m going off the calculator synder offers for their membranes

Pressure x flow / 1460 gives you hp requirement for flow at that pressure

We’ve tested this and it’s pretty spot on

Take that hp requirement and convert it to kw, then factor in 3 phase to get amps

Idk the motor inefficiency im just guessing

Look at the math Lincoln posted

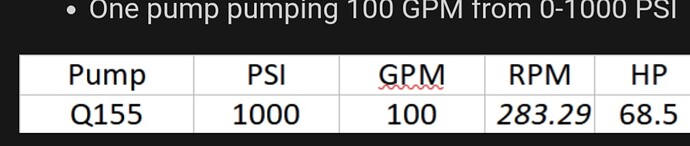

1000 psi x 100 gpm / 1460 (which is my calculation) is 68.5hp which is what he posted

That all sounds right, I’m just pointing out that the efficiency doesn’t “compound” because there are multiple pumps. And by operating one of those pumps at a lower head more happily within it’s curve, @MagisterChemist technically probably does have a more efficient design. Frankly, I doubt very much that there’s enough of a difference to fret about

To pump with one pump is:

53 gpm x 1000 psi = 34 HP

So yes, the energy use is lower.

Btw anyone @trust_level_4 want to split this? This has nothing to do with DIY…

Some of it does, the power calculations thing is definitely relevant

If you can find a pump/motor combo that can move 53 gpm at differential pressure 1000 psi and has an FLA less than 21, i would be happy to see it… I am quite sure it does not exist.

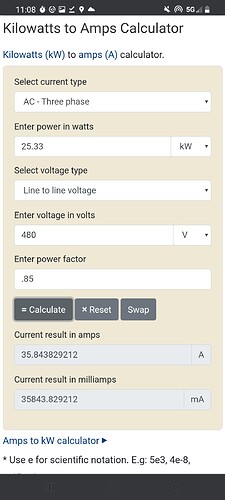

53 x 1000 / 1560 = 33.97 hp = 25.33 kw

25.33 kw is 35.85 amps at 1000 psi

You run 600 max with synders so 35.85 / 10 x 6 = 21.5

According to hydrocell though it takes 68.5 hp at 1000 psi to get 100 gpm, (1000x100)/ 1460 is 68.5

Your calculation would be (1000x100)/1560 which is 64.1

Do the math for yourself if you doubt me

Not saying you’re right or I am, we have very similar power calculations though

It’s probably closer to 23 amps on 480

No, the 21 amps i listed was FLA – and the system is rated to go up to 1000 psi and 53 gpm. That number is again FLA – in actual use, the number is lower. For though i may run at 600 most of the time, all the hardware was sized to be able to go well above that.

Show what pump/motor you can do that with 23 FLA – I’m not buying that either.

Using 480v, when starting a system in the field today, I was pulling 3.8 amps to recover 90GPH. Here’s the screenshot of the panel. This isn’t theoretical. This is on a working system. I think y’all are recirculating too much. A single pass is all you need.

I’m not going to recirculate for solvent recovery

I’ve found that permeation rates only drop off after about 50% permeation is achieved so with a slow creep and enough surface area you can do it all in 1 pass (I’m sure this is what you figured out long ago, and I will admit I talked shit. It works for solvent recovery but you’ll foul the shit out of winterization membranes without more cross flow I’ve found), this is why my 60 gph will have 4080s now instead of 2580s.

I’m over sizing my pumps though so ppl can add housings later to expand because I feel like this will be key

480 v 3.8 amps is like 2.68 kw for 90 gph solvent recovery that’s beast

So… Any amendments to my suggestions for DIY parts, membrane selection, etc? I am trying to give people info to do their own r&d here… Discussions about the different marketed skids are not really what this is about

Kingoftheboof strikes again

Always make the feed 1.5 x the output hose diameter

High flow pumps do not like to be choked, it can damage some diaphragm pumps (cat specifically, hydrocell can run dry though im pretty sure)