Yeah we’re making weird jokes. Ignore us.

If I know one thing, it’s that I know nothing… or so close to nothing as makes no difference.

But if I had a gear meter like the BHOmeter I could probably claim that I know how much solvent I’ve dumped over my cannabis, and that’s a useful thing.

Add that to temperatures and pressures and starting concentration and how much % is left in the “waste” and maybe there might be a tiny bit of knowledge hiding somewhere.

Ah yes, natural limits of knowledge

If you’re the fellow that wrote about that “early extraction facility”

Truly an amazing job…

And I would expect nothing other than Mil. Spec.

QUALITY from you.

Perhaps you haven’t noticed the number of clowns who think they’re “extracting with BHO”….or maybe you have.

Edit: ![]() or maybe they are?!?

or maybe they are?!?

do you mean using non concentrated BHO as a solvent as in counter current?

![]()

maybe

I knew this guy that ran like 8 columns all daisy chained together lol

With the “new and improved BUTANE” …if you get chalk before it comes

out of the extraction column/tank…Mr. Solubility is telling you some thing.

the trick is then sequencing the solvent/tincture. I added that capability (upon request) to a system (4x 6x48) I built fairly recently. the added complexity was (apparently) not worth it. owner didn’t request it removed, but agreed that bottom fill had more utility.

I liken us to one of those translucent deep ocean creatures rarely observed by humans, now washed up on the beach. Weird yet fascinating, terrifying yet beautiful, but after a little monitoring, the healthy skepticism fades and it’s discovered to be the embodiment of evolution/survival of the fittest. An entity who evolved to survive in the harshest conditions and adapted to outsmart countless natural predators. Champions of natural selection, inviting all of you to bear witness to our next evolutionary transformation.

lol. Love the natural predators metaphor. Wish I wasn’t so new to extractions so I could win a unit.

As in, the solvent goes through all 8 tubes in a row? Seems like. A lot of loss at the end of the day

Cool Post. I like your outlook towards the community, and I’ve appreciated your historical perspective and knowledge born from experience.

I’ve got a couple ideas…the last one might get me chased out of here with pitchforks…But, it might be the most lucrative for you also.

In my day to day, I see myself moving a flow meter around to really dial in my processes and collect data. The one I’d like to play with most is using the flow rate information to help me quantify and make empirical judgements around my CRC column and studying how media bed height affects remediation. With like material and material:media ratios, a large run will result in more remediation IME. As I understand it this is due to column height and residency time. In the realm of “art” not “science”, I do dial back my medias some in larger runs compared to same material in smaller runs. But, I’d really like to know how much of this is residency and how much is column height. If I ran 2x as much media and I flowed 2x as fast, is the remediation the same? I can see the flowmeter helping me answer these types of questions.

BUT…depending on how you feel about automation, here’s the one that’ll get me chased out of here…

The biggest potential for flow meters is in automated extractions. On the development side of automated extraction, the flow meters will be able to take information from runs performed by master extractors and allow for programs to be written that mimic the parameters. On the use side, flow meters will be integrated to maintain normal running conditions ie: maintain balance between inject and recovery, etc, etc…But, I see their biggest potential being perceiving plugs and other run abnormalities. The biggest open question for me about automation is how will it perceive and respond to an abnormaility? And, flow meters are critical for this. If you’ve got the best flow meter on the market, you’ll become rich if you can court automation guys.

Cool project. I like the initiative. Pretty please, may I have a $5K meter. I’ll put it to good use and I’d happily support your development by giving you feedback.

Good post. And you brought the convo back to use cases… so you’re definitely in the running.

We are in talks with a bunch of system manufacturers discussing integrations. Alao software companies looking to utilize real data without counting on the operator to manually input it.

Most importantly… we are waiting on our first order of cryo valves w/c1d1 actuators. Once they come in… for ballpark $10k, one can retrofit their system to be semi-automated. Just by way of the flood valve shutting at the desired point every column will drastically improve run consistency and help the operator identify the source of the good/bad results by way of eliminating a huge variable.

As for your crc/residence time question… I wanted to do the same. Prior to the flow meter I made a little laminated “sundial” type thing that was fixed under the valve handle. It was the only way I could attempt to establish consistency between. Operators. And one of our iPad inputs was the position of that valve… i.e. crc valve: 12 o’clock. Meaning fully open. 3 o’clock was fully shut.

ball valves are horrible for that application…

(needle valve, and a BHOmeter)

The sundial trick is a good spoon. It’ll put those little threaded collars behind the valve handle to good use.

Yes, you are very smart to court the automation market. I’m helping a small equipment manufacturer RD test a piece of equipment. Everytime the guy comes, he adds some new sensor so he can grab more data.

Are you saying ball valves are bad for the flowmeter or the sundial trick?

Is this because the aperture size/volume does not roll on at an even rate? IE: The same amount of turn at the beginning and end of the 90 degree arch changes the volume less than that same amount of turn in the middle of the 90 degree arch?

The small amount of turn results in less fine tune adjustment? Sometimes when dealing with a very reactive run, I feel like it’s difficult for the human hand to make minute enough adjustments?

Both?

Or something else I’m missing?

Cheers!

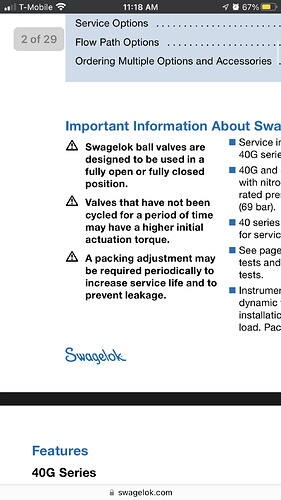

they are not DESIGNED for the task…they work, but many manufacturers explicitly state “don’t do that” (see Swagelok below).

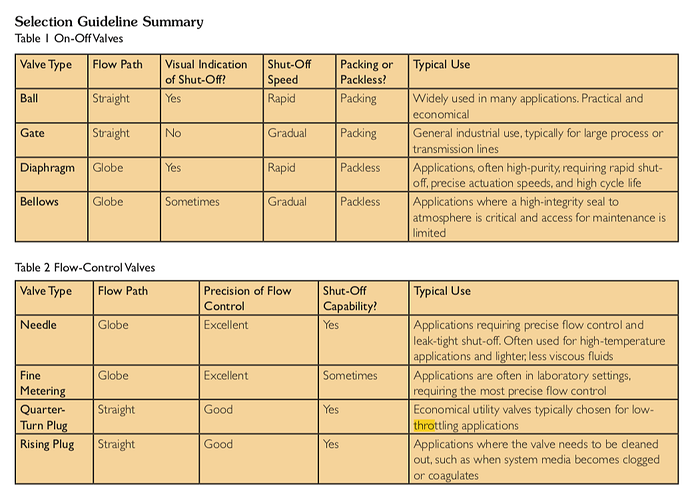

https://www.eng.ufl.edu/labsafety/wp-content/uploads/sites/28/2015/04/Valve-Selection.pdf

So, all of above to my questions. Thanks!

Read the Manual, yes even on your valves!

Actually ESPECIALLY on your valves! You’ll learn a lot.

To add what @cyclopath said ball valves are just the less superior(and wrong) option, when used as a restricting valve it will cause the seats to wear out quicker and potentially not allow you to close the valve off completely when or if the time comes where you need to close that under pressure you may wish you would have sprung for a proper valve.