If I get the flow meter, I’ll have to replace them.

You should replace them already if if you restrict the flow with them at all.

Now I’m not gonna argue that I know more than swagelok… @cyclopath, thanks for info/source! But practically speaking I imagine almost every operator on here has been partially restricting their ball valves for a long time. @thesk8nmidget… any guesstimate as to how long it take to wear one out? Probably relqtive to pressure/temp/etc? I’ve replaced plenty of valves over the years. Perhaps this was why!

Ever had a ball valve lie to you?

Most disconcerting.

More flow when ostensibly closed than open.

Bet you can guess which valve that was…

I have been guilty of using a ball valve as a flow restriction. I’m sure 95% of people running CRC are as well ! What I can say is that after 2 years of improper use my titan & swagelok valves have not leaked or had any issue . I will have to buy a needle valve for after the crc to throttle flow . I would be especially careful of doing this with regular WOG valves . I have had them leak plenty in the past usually fixed with a quick tightening of the packing nut but sometimes they are just done for

The sundial deal was all I could think up on the fly to attempt to standardize between operators. We ran 24/7 for years… and I couldn’t be present all the time.

Another thing I did to attempt to standardize across operators and have more accurate data that is maybe worht sharing is…

At some point(not as early as I wish!) I came to really understand that data was rhe key to this business. Once I had a system in place… I could only improve things if I knew as many things as possible. And once I was cool with the current set of SOP’s… scaling up was just a matter of inputting more material(and everything that comes along with that)

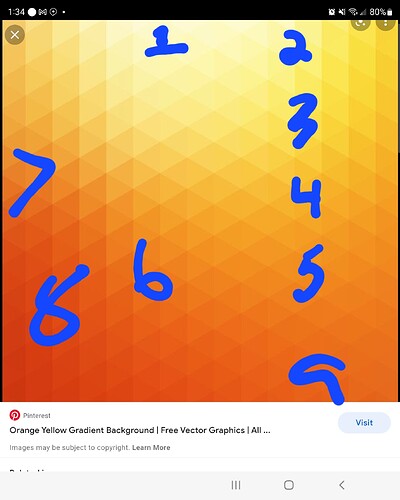

So we were attempting to record run data about color/clarity/nose.

For a while the spreadsheet would just say yellow… golden yellow. Orangy yellow… brownish Orange. Etc.

So I found some nice gradient images that I blew up large and had them printed at a print shop and laminated.

Then wrote numb3rs on them in sharpie. So operators could pick up a piece of shatter and hold it up til they found a real close match. And record a number as oppose to a description.

.

This was key to us refining our crc processes/blends.

Yeah, we all use them that way.

I try and get needle valves any time I actually need fine grained flow control.

Not being able to shut off (actually open fully) the dump value wasn’t catastrophic…but it sure reinforced “right tool for the job”.

Edit: that valve is now our swaging fixture (right job for the tool)

Not long 3 months maybe, but another thing to consider is this valve was the last line feeding the the recovery vessel so it probably has thca crystallize on it due to current fast crash gas which made for an abrasive ball and Seat that helped it fail sooner that a valve that never had thca crash out on it.

Gotcha. I always had the crew flush clean solvent through thr top rail of out rack to the crc… Can’t remember the yield difference… it was probably t years ago, ans granted my ability to isolate ariables to test wasn’t as strong back then. But I think it was significant. That probably helped a bit with the crystalline build up. But I see how that could be rough on the valve.

As someone said, and I see often, is a way to measure the amount of solvent, and the time, that is going into the crc

At the begining, since one is still flooding the columns(again) then one can count how much is going into they the crc with the scale on the solvent tank

But when one switches to pushing the solvent with n2, one has to gauge by eye how much is going into the collection from the crc, per minute, and it’s A) a pain in the dick to watch the collection when it could be correct and automatic, and B) fuck I can’t remember

Yes a needle valve would make it easier to be more precise but it’s still eyeballing shit