No this was a user posting here about their facility.

Found it

Only a few posts about it, basically saying the same shit people have said here LOL

Well that wasn’t as helpful as I had hoped haha

No this was a user posting here about their facility.

Found it

Only a few posts about it, basically saying the same shit people have said here LOL

Well that wasn’t as helpful as I had hoped haha

I doubt 30 psi and a little bit of warm water will hurt… though maybe you’re right I’ll look into it more and rethink it

I wonder how many of these are out in the hills from all the fires.

Definitely look into resurfacing the seal flanges minimal

Is it warped? Have you tried bolting another flange to it?

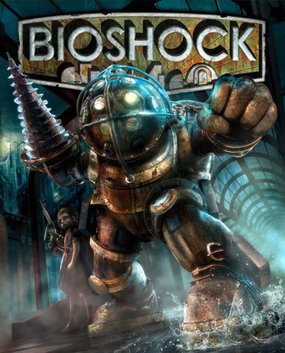

You need to kill the girl and her protector. Take the protectors gear and you should be golden to keep extracting.

Don’t be a fucking moron. That thing is toast.

Why do you think it’s toast? Because it has slight discoloration? ![]()

![]()

![]()

![]()

Because the heating and cooling processes that tank has seen probably wasn’t conducive to a proper annealing. You don’t know how hot it got while it was in the fire and you also don’t know how quickly it was cooled.

If somebody hosed that thing off while it was hot I’d say that it’s probably not safe to use because it will be brittle as hell.

Either way it’s a profoundly stupid gamble.

I’ve taken that into consideration. Maybe I’ll just make it into a bbq. Maybe I’ll use it… dunno.

Could have it x rayed. Probably would want to get a quote on pricing since not just the welds will need to be checked.

Stainless usually is tested with phased array ultrasound. You could hit the whole thing with dye penetrant and developer

Shows u how much I’ve messed with stainless

Ok so what if it slightly less aspergers than it was before and got a tiny bit miniscus… is it really an issue with 30-40 psi and hot water running through it? Oh yeah and the cold butane forgot about that but still… I see no issues…

What’s got me concerned is that cracks may have developed in the side walls. If there are cracks that have formed, then using it in an application where it’s gonna alternate from cold to hot often is only going to make those cracks grow with use.

That’s cracks potential to eventually rupture is compounded by the fact that it’s a pretty large vessel. The longer (in length) the crack is able to propagate, the weaker the whole structure is and the more likely it is to fail catastrophically.

If you want to use it, just talk to someone that can tell you if cracks have begun to form.

You want you use butane in this and hot water and see no problem?

Always plan for the worst and this might be the worst idea on this forum right now.

Do not use this for a gas. Maybe ethanol as a holding tank but not as a sealed pressured holding tank.

At the very least, treat the rust and penetrant test it. It’s like $40 for all you need to do that and it will show you any cracks in the developer

I still say scrap it, personally

That developer solution is fool proof stuff huh? I was assuming when you mentioned it, you’d still need a professional to interpret the results.

Best practice lol

A professional is always a good idea, but it’s easy enough to spot any glaring flaws

There’s also UV reactive options

That’s pretty sweet. @Rainbowp3nis this would the ticket. Probably sand blast that thing first. Or soda blast so you don’t rough up the gasket surface.

Also, for a replacement on that sight glass, a new slice of borosilicate of the same thickness and diameter can replace the one that broke. Assuming the flange isn’t warped at all. Do you have a good steel square and some feeler guages?

Unfortunately we do not price match typically. And please make sure that you are comparing apples to apples. I have seen tanks (non jacketed) at that price and single jacketed tanks for just a bit more. I haven’t seen a double jacketed tank that low, not saying one isn’t out there.

As welder and metal fabricator for over 20 years, and working in the aviation industry also (everything is dye checked or mag tested), I would also suggest doing a dye check. It is something you can do yourself. I caution people on doing any blasting before dye checking, as the blasting can actually form a small layer of metal over a minor crack, and the crack would be even harder to see. I would advise on a chemical cleaning process before the dye check. Also when hitting it with the light, make sure the room you’re in is completely dark. You want the best chance of seeing a fracture or crack that you can get. Just my .02 of course.