PVA - poly vinyl alcohol?

you can order some LSO through me at Scientific Solutions which is made for spray drying?

it would take away all the guess work

It’s probably cheaper to just mimic the recipe if you know the ingredients. Same way people can order “nanostabilizer” from SonoMechanics to do a liquid nanoemulsion, it’s just cheaper to create your own recipe and order the ingredients individually in bulk.

I would guess @tokesandtinkery is one of the many people here who prefer to recreate a cheaper solution. I know I prefer to do some R&D to understand what’s going on and then create a cheaper solution from said R&D.

Also @tokesandtinkery , I have access to that full paper you linked. Let me know if you want a copy I can share it with you.

Polyvinyl acrylate? Elmer’s glue?

PVA is normally polyvinyl alcohol. The paper that was also referenced confirms PVA being polyvinyl alcohol as well.

I enjoy the process of learning, experimenting, seeing the evolution in my work. I had no interest in nanoemulsions 6 months ago, now I can make ‘em 30 different ways, with and without ultrasonication. I can experience myself the pro’s and cons of each method, of seeing true nano. Soon, I’ll have sub micron particle analysis capability. How cool is that?! I’d never have touched the subject otherwise. Thats the value to me.

Has anyone played with liposomes?

thats awesome! mclain is the man for sure!

Care to share one of the methods without sonication?

High pressure homogenization is another way of doing it, very common in industries such as dairy, soft beverage, pharmaceutical delivery.

If we’re only discussing nanoemulsions (high-energy), which are not the same thing as microemulsions (low-energy spontaneous or phase inversion techniques), there are four primary techniques:

- Ultrasonic homogenization

- Microfluidization

- High-pressure homogenization

- Ultra-high-pressure homogenization

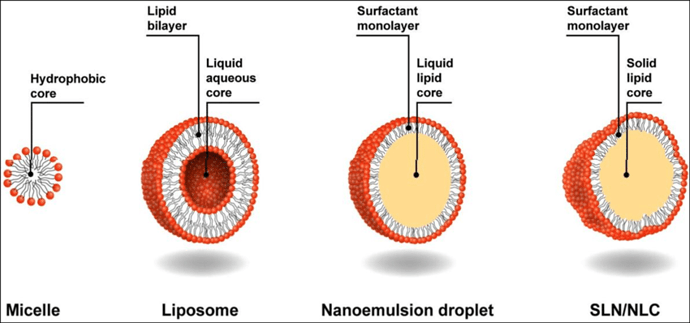

A nanoemulsion is a colloidal liquid-in-liquid dispersion of two immiscible liquids; from two phases (ex., oil, and water) into one phase. A colloid from an oil-in-water nanoemulsion, the kind this thread discusses, has a hydrophobic liquid core composed of the oil dispersed in the water and stabilized by a surfactant monolayer.

A nanoliposome is a nanoscale bilayer lipid vesicle colloidal system where the a.i. is encapsulated through the application of high-energy. These vesicles are comprised of a core surrounded by a double phospholipid layer. It’s typically prepared using the high-energy methods for nanoemulsification, Mozafari (heating), or membrane extrusion.

A microemulsion forms micelles with “a hydrophobic core which is formed by the tails of the surfactant molecules” You can read a bit more about micelles and their preparation in this post of mine

Not yet, but I will soon. Nanoliposomes to be specific.

Very nice of you to share this SOP with the community. Great write-up. ![]()

![]()

There are process flow optimizations that would be worthwhile to include. Still, overall this is a great intro, especially for people who don’t know how or can’t formulate their surfactant system in-house.

If anyone using this SOP wants to save some money, you can get a better emulsifier formulation from CannaSol Technologies. It uses the same surfactant as the All-In-One from ISE, modified coconut oil, while offering an improved formulation at a lower cost. There are two options from CannaSol. A complete formulation called NanoOptimizer, or Nano PreMix, which doesn’t include potassium sorbate and acid (they come with Nano PreMix and add them yourself).

Both options are less expensive than ISE’s All-In-One. The Nano PreMix offers greater price savings because it’s a two-step process.

Also, the sterile filter capsule from CannaSol is way better than what ISE offers. Overall, CannaSol is a better turn-key solution than ISE, at a lower cost. It uses the Qsoncia Q2000 ultrasonic with custom desinged horn by CannaSol and a really useful automation controller for running flow-through mode. However, after I spoke with the ower last week, I suggested a simple method to use the automation controller for batch mode, too!

Did you end up playing around with nanoliposomes?

no not really i sold my RnD machine for a Freeze dryer lol

Hello Everyone. I’m new here and have been experimenting with Nanoemulsions after getting the hardware collecting for 6 months. Ive been lurking here for a few months.

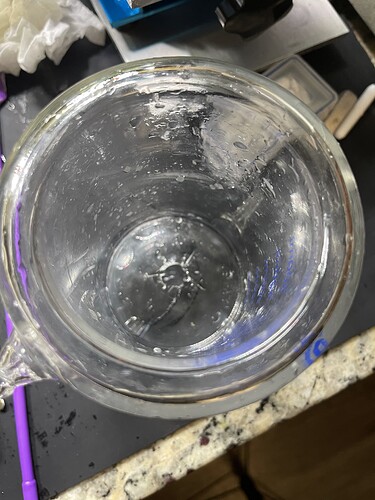

I want to strongly warn you about that jacketed beaker above. I never believed this until now, people said to me the Chinese glass sucks. My horn was submerged about 2/3 into the coarse emulsion as I turned up the intensity I heard what sounded like a gunshot and my jacketed beaker “inside” which is connected to a recirculating chiller which I was able to stop before the emulsion hit it. FYI in my case I was using the 500ml last night when it blew. Chinese glass is 1/4 the price of american or less but I blew a lot of money last night.

FYI - I will have 4-5 fully equiped sonicator systems up for sale in the next 30 days. Qsonica, Fisher, Sonics and 3 Misonix.

I hope this helps with anyone using chinese glass.

Regards

I always put my beaker (250 or 500ml) within a 10L beaker lined at the bottom and around the sides with those plastic re useable ice cubes… ridiculous but got the job done

That works excellent also, great idea with the plastic cubes, I started with an ice bath but then found a good deal on a used recirculating chiller for $100. I am working on a new chiller for non-jacketed beakers like the Branson Ultrasonic Rosette cooling cells. I took a Desiccator vessel and I am wrapping copper coils on the inside where I can put any beaker to be chilled. I acquired a few of these which have worked well.

Hello im french guy .is very difficult for me to have information for the materiel and process .you can help me ?