What a pleasure to read. This machine seems to be the best thing to happen to carts since sliced bread. Really liked seeing that you have updates for it every month. Long term this machine is a winner imo. Reminds me a lot of Tesla updating their cars. Really you can set and forget it as long as you have your employees working on something else, which i think we can all agree that adding the role of “add the cartridge tray into the machine” is going to break anyone. For companies that are serious about manufacturing this is a no brainer. We have had multiple machine from china and then went with qma to try the other side of the curve but i think this machine will be the next investment.

The guy knows his stuff. We talked for a while at Mjbizcon he is a stand up guy. I can’t wait for my wand style ones. They’re a dream come true.

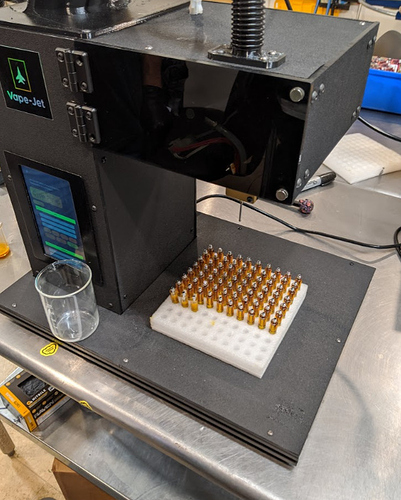

Almost exactly 1 month later. Not quite production yet, but getting very close. The first few units will begin shipping this month to those impatient, with the expectation that the software will be updated to a cleaner version over the air =)

Over the next few days I will reach out @SanitatemDime and get this ready. I’m going to take it to a local lab and test with some rosin just to ensure that it still can pump effectively. (I lengthened the line from the reservoir to the valve, and decreased the line length from the valve to the needle, as compared to VJ3.0.)

Looks beautiful.

I’d still like a wand one but we can figure that out once everything’s working ![]()

I might work on a wand attachment for this version ![]() However, for now it seems to be working out pretty well.

However, for now it seems to be working out pretty well.

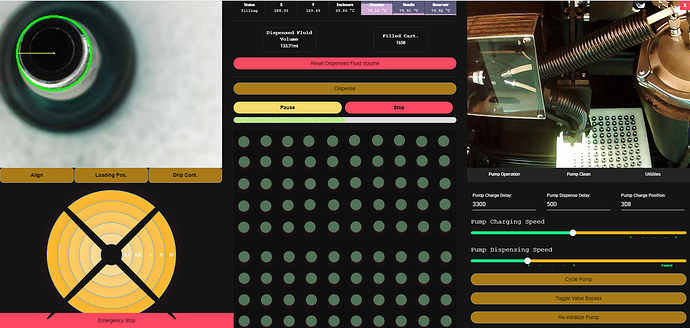

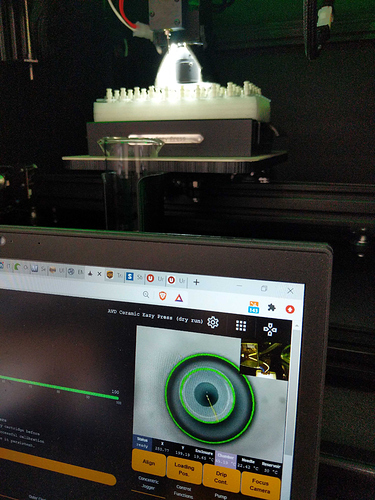

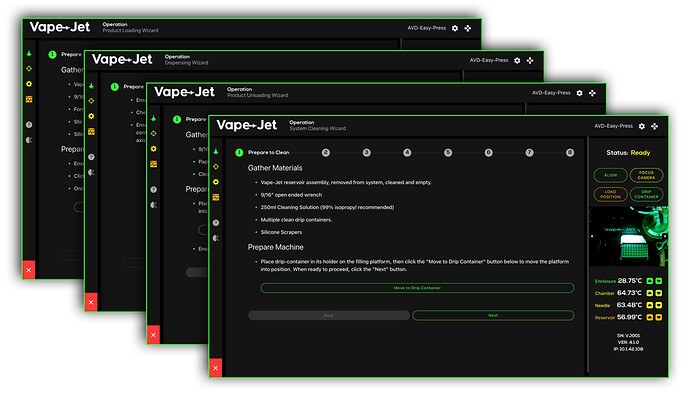

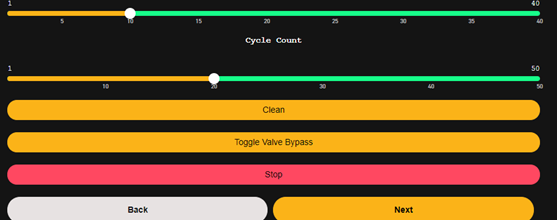

The GUI is rough, but everything needed is there. It runs 100% from the touch-panel, however if you plug it into a network (RJ-45 Jack in the back) it can be setup so we can help configure it remotely. It is also possible for us to do remote software upgrades of each machine, so the GUI will be updated as I refine it.

Been doing testing over the past two days with a few of our local partners. Nearly ready to go!

![]() does this come standard on every model? Love it

does this come standard on every model? Love it

Trying to figure out a way to integrate it as an easter-egg or something.

Might be a screen-saver option.

It would be really cool to somehow gameify the filling process, so each cart filled kills a demon and moves you through the level. However, that will have to be after it ships, thankfully it is remotely updateable =)

Moving the discussion of the semi-auto version to Jet-Fueler Semi-Automatic Cartridge Filler

It has been a while since I have updated this thread with patch notes, so here are the recent changes and upgrades made to the Vape-Jet 3.0 system.

-

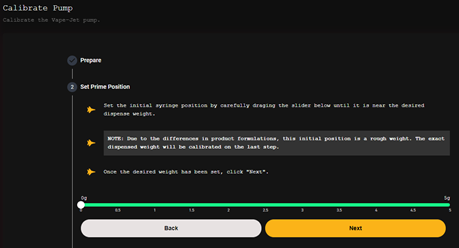

Reworked the pump calibration wizard. The wording is more correct now, and we eliminated some of the confusion between measurement types.

-

Live-chat has been eliminated and replaced with a ticketing and helpdesk style system. Please feel free to use it and submit bug-reports, suggestions, service & calibration requests, and training requests.

-

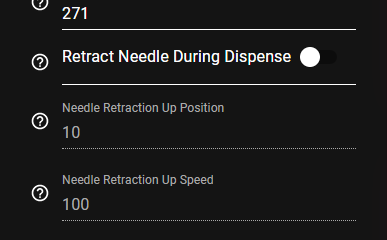

Needle retraction feature. This new feature allows the Vape-Jet needle to be retracted from the cartridge during filling. This both helps increase dispense speed as well as help eliminate drips that may form on the outside of the needle.

Retract Needle During Dispense – (ON/OFF) – Toggles this feature on and off.

Needle Retraction Up Position – (Position) – This should be set to the needle location you want the pump to end at. Depending on the speed, this can be at the very top of the cartridge outer wall, or slightly below it. This will ALWAYS be lower than Needle Up Position.

Needle Retraction Up Speed – (mm/min) – This should be set to the speed (measured in mm/min) you want to retract the needle during retraction. (Good default value to start with is 400)

-

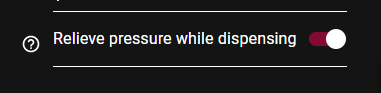

Pressure Relief Toggle – You can now toggle the pressure relief motion on and off as needed / desired. This will lead to more drips, but vastly improved throughput.

-

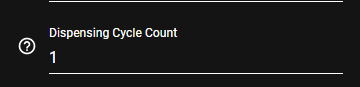

Dispense Cycle Count – This is a feature specific for filling bottles. It allows us to make >5ml dispense actions with only using a 5ml syringe. (For example, on a 15ml bottle this would be set to 3)

-

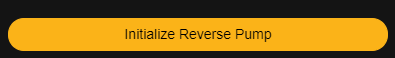

Initialize Pump Reverse – This will initialize the pump by pushing out the product from the needle side, instead of the reservoir side. This is useful if the pump gets a back-pressure error and re-initializing it does not move the plunger to the 100% down position.

-

Focus Camera Safety Position – This feature will move the platform out of the way during the focus cycle, to prevent accidental machine crashes.

-

Saved Routines – This is an advanced feature which should not be used without Vape-Jet guidance. It enables us to create pre-defined routines for some customers if they request it. These routines are generally for special cases, such as dispensing to a jig without the use of the machine vision system.

-

Stop Cleaning Cycle – Self-Explanatory. Allows you to stop a cleaning cycle while in progress.

-

In addition to the above features, we also made some behind the scenes changes to the dispense cycle which should decrease cycle time by ~30 seconds per tray. We also got rid of the pump reinitialization at the end of every cycle, saving another 5-10 seconds.

-

And finally — we added “Advanced Operation Mode” This mode allows you to track approximate reservoir usage, reset that usage, dispense without using the wizard, and modify pump parameters in real-time. You can change the pump position, delays, and speeds mid-run for tuning purposes, as well as to correct issues without needing to stop the entire run. All main operations functions can be accessed from this screen, but it is not intended for setup or calibration. It is pretty much operations only, but streamlined for that use.

Due to requests to minimize cycle times between filling and capping, we have introduced a new mode for the Vape-Jet system which scans the tray, and then fills, rather than fill->scan->fill->scan.

This new mode can speed up the time between first fill and capping, at the expense of a slightly longer total cycle time due to performing actions sequentially rather than concurrently. If working with extremely thick products, this mode won’t help much as the alignment and measurement cycles take place faster than the pump is able to fully recharge. However for thin product formulations ran hot, where cartridge leaking is a concern, this can reduce your time between fill and cap.

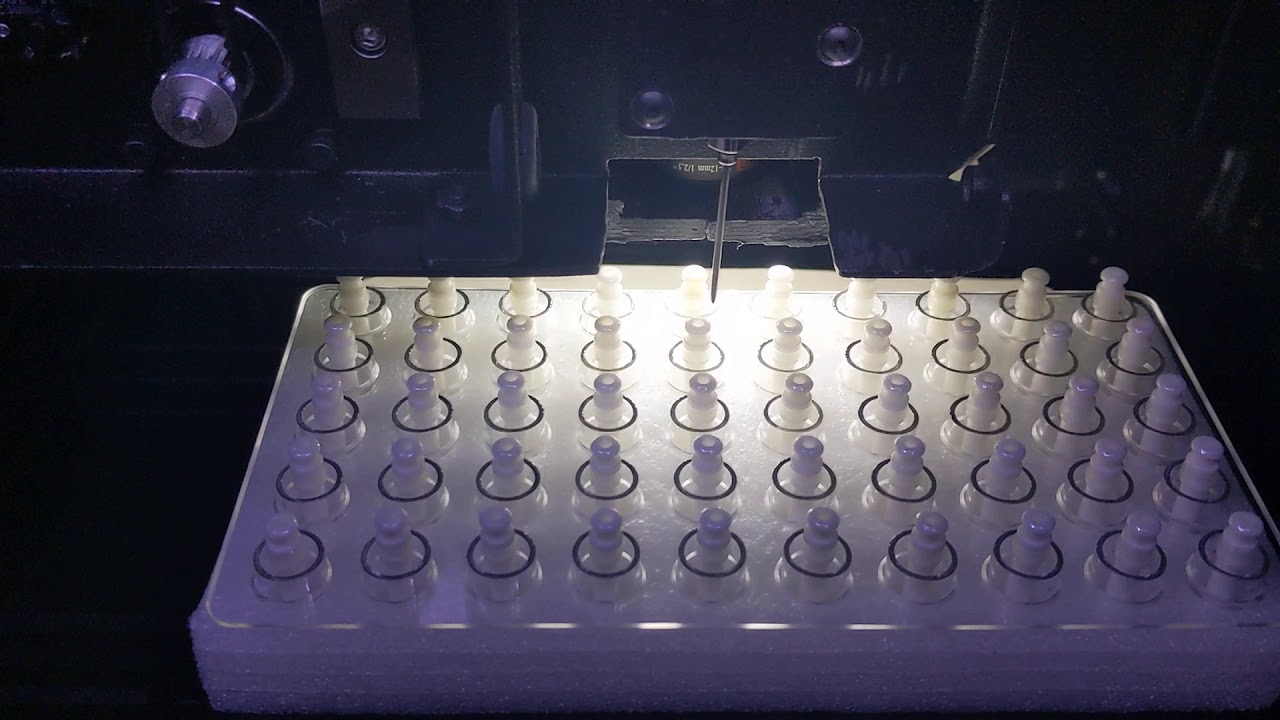

The cartridges in this video are ceramics, and tend to have a bit more center-post variability than most. Center-post avoidance is turned on, which measures the center post to outer wall offset. By measuring this offset we are able to calculate the best vector for needle placement in relation to the center post. (AKA it will go to the widest point, not the narrowest.)

Can this be used to fill gummy molds?

Yes it can with a little custom work, nothing we wouldn’t handle on the backend.

What’s your lead time on your machines right now?

We have 1 Jet-Fueler boxed and ready for shipment that is unclaimed. As soon as payment clears it is available to ship to the next customer. Please note that this is subject to change rapidly, and we do not always have machines available with 0 day lead time.

Vape-Jet systems are currently backed up to about 10-12 weeks, but that is starting to come down as we expand our production floor.

tldr; We released a software update that makes our existing machines up to 30% faster across the board by improving the machine vision algorithm and pumping logic. This software update is available for free to any existing customers, and will ship default on new machines.

#activedevelopment

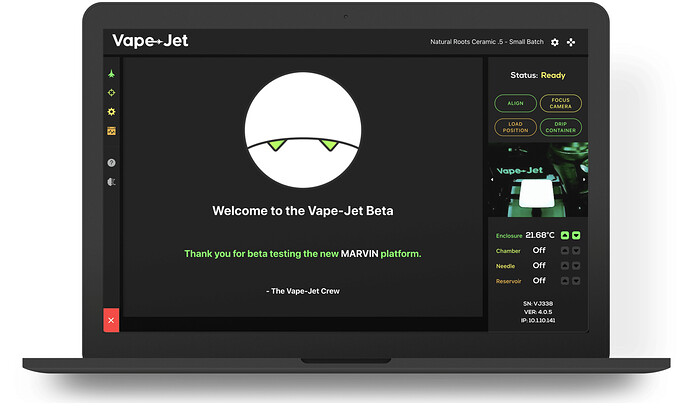

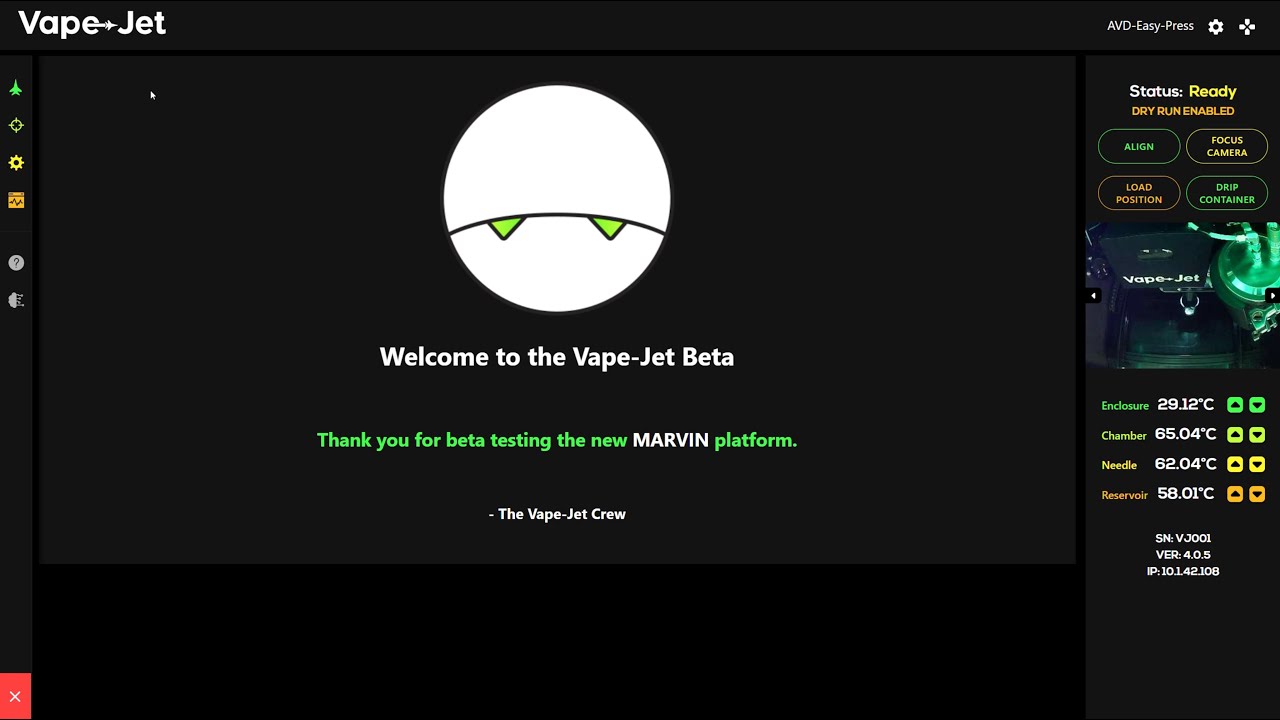

Get Ready for MARVIN

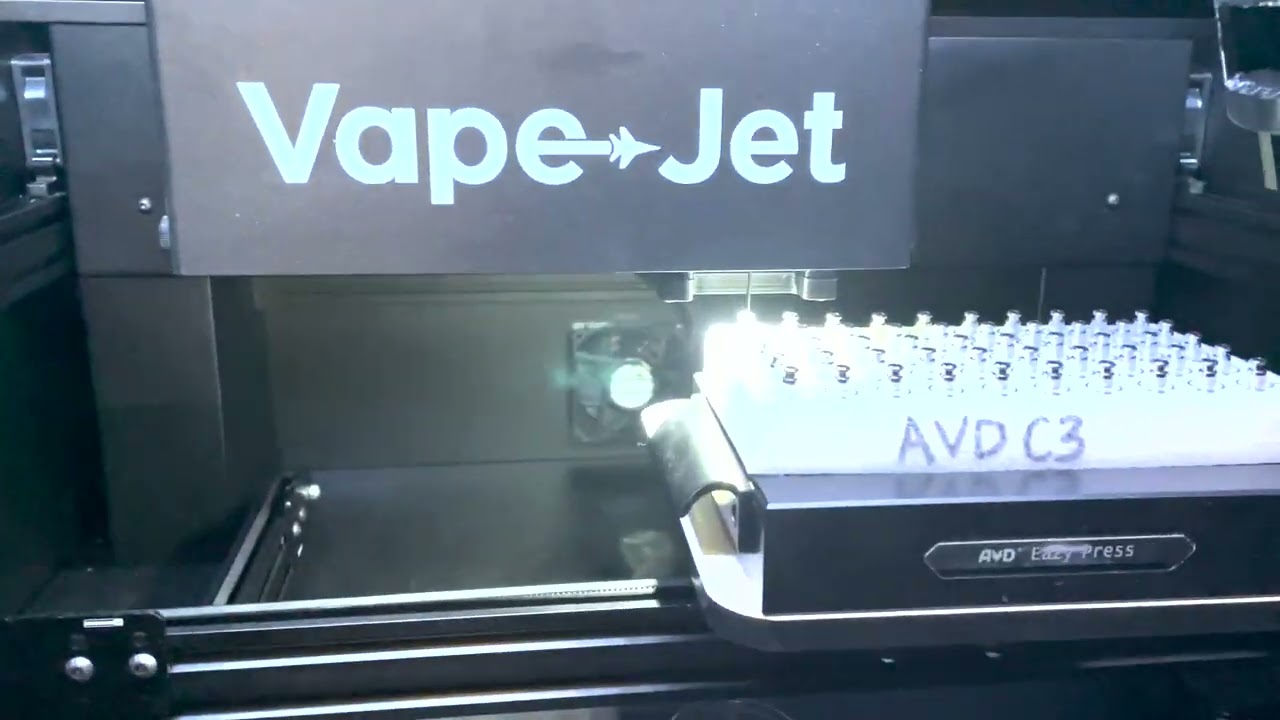

From the beginning, we set out to build the Vape-Jet 3.0, fully-automatic vape cartridge-filling machine to change the game—this meant not only designing the most innovative hardware but also programming our software to set the highest production benchmarks on the market.

Boasting increases in daily output of up to 30%

Faster Processes

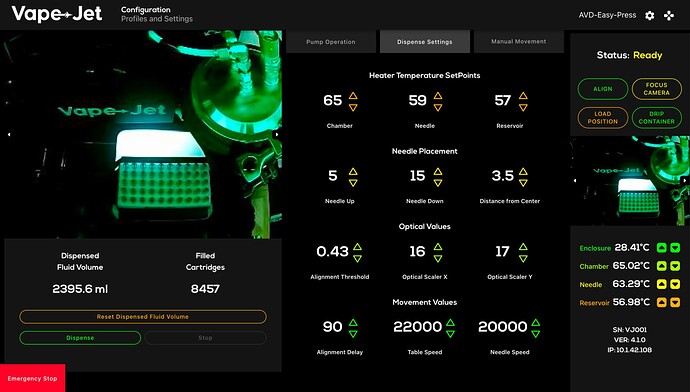

MARVIN optimizes the Vape-Jet’s fully-automatic processes to run even smoother while giving users more customization options.

Enhanced Cartridge Identification

Maintaining the precision and accuracy of the Vape-Jet 3.0’s onboard machine vision camera, MARVIN software upgrades reduce the time between cartridge alignment and filling by more than half.

Configurable Camera Exposure

MARVIN enables users to manually adjust the machine vision exposure level, eliminating auto exposure errors and reducing cartridge alignment time.

Custom Cleaning and Drying Cycles

Simplify your cleaning processes and reduce the need for additional user input by setting custom cleaning specifications.

Dispense Logic Optimization

MARVIN reduces the number of valve and pump movements during the filling process, increasing daily output up to 30% by pulling more product into the syringe and distributing it sequentially before needing to recharge the pump.

Redesigned User Interface

Automated Vape Cartridge-Filling Systems can appear intimidating, but not so with this new software. In fact, we’ve overhauled the entire user interface, moving extraneous elements to the advanced panel so you can focus on the essentials.

Upgraded Interactive SOPs (standard operating procedures)

With this software upgrade, we’ve updated all Vape-Jet SOPs with supporting visuals to guide users through decision-making processes and emphasize consistent usage while shortening employee training times.

Improved Error Handling

When encountering errors, MARVIN automatically initializes and resets the Vape-Jet 3.0 pump system, reducing clogging from fluids left to cool. Furthermore, the new software links directly to product support documentation, allowing users to easily submit a HelpDesk support ticket.

Dry Run Mode

Don’t worry about switching between separate profiles for testing and production. With the brand-new Dry Run Mode, users can now simulate fills without dispensing any oil, reducing errors and product loss.

Global Settings

With MARVIN, we’ve simplified machine setup and calibration by moving useful settings from individual configurations to machine-wide profiles, cutting down on training time and human error.

Improved Management

Our unrivaled product support just got better. With new Vape-Jet software, your machine is fully integrated with our support and maintenance systems, allowing us to provide more effective product support, predictive maintenance, and reduce machine downtime.

We did a thing, and upgraded everything about the Vape-Jet system. It now plays doom natively with shaders and GL additions. No need for a 2nd computer.

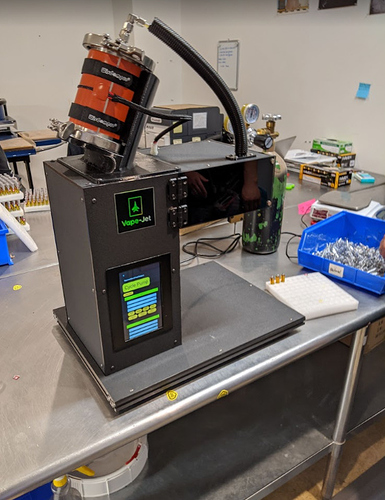

Also a bunch of upgrades like new electronics, upgraded stepper drivers, all aluminum construction, long-life bearings, increased ceramic valve diameter, touchless proximity sensors, increased motor torque, and a operator / technician focused design reducing downtime when service or replacement is needed.

Have you considered increasing the size of the oil well. You cant really fill 1k in a batch as it typically comes out short. Having an option for different well sizes would be great.

Overall the new 4.0 looks great. Just need to get my marvin upgrade now