Why is it i only find these fats in old outdoor material that I didn’t grow inside? Jw

I’ve ran it rather warm right behind it the 2nd run wasn’t worth it was so small awful color nasty taste

But evaporation does cause temperature drops

I wanna know what causes fats in the stuff I get out west thats couple months old…I never ran into fats untill I started running other trim

Indeed, check out adiabatic cooling

have you ever winterized in etoh? Almost all extracts will have fats/ lipids in them.

Take your best nonfatty extraction and dissolve a small amount perhaps a gram into 10-15 ml of 99% etoh and freeze overnight. post a pic

yeah and w my 2" and 3" jacket w most all the trim I’ve grew and run I’ve run never makes anything until I started running outdoor couple months old from Cali

It was a surprise after running fire material for so long I was growing. Maybe I got lucky for4 years picking strains w low fats

trust me when I say fats are in all biomass, even already extracted biomass will have some lipid content.

minimal id say but I guess I don’t know…I know I’m not the only person here that feels this way though

I’ve been told this by tons and seen it myself but must been fire ass stuff

But yeah I’ve ran into material before that made fats I didn’t grow and outdoor usually

On a small <1lb run, would pre-freezing the material to -90c or so be sufficient, versus needing a dewaxing column? I’d like to get a small CLS to play around with and not sure if the expense is going to be worth it if pre-freezing the material is sufficient

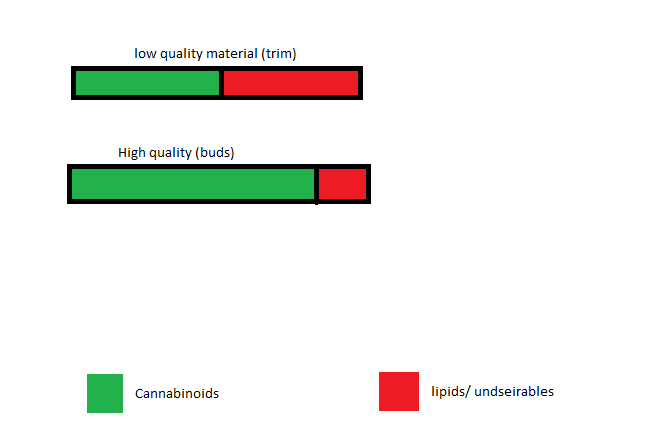

trim is nothing like running bud or whole plant, less cannabinoids to extract same amount of lipids.

@StoneD If you extracted both of these you would see similar trends when made into a concentrate. When extracting high quality material you will see better results than trim, furthermore the cannabinoid content would be greater as well.

Imagine this:

- assume all plant material has the same amount of wax

you extract 1 lb of trim @ 10% yield: you have 43.35 gr of concentrate

you extract 1 lb of bud @ 20% yield: You have 90.67 gr of concentrate

See how this doubles the cannabinoid yield with half the plant material? This is still assuming that all plant material is equal in lipid content. Eg you will have a ratio of lipids per cannabinoids that is overall lower.

Simply put… fire in fire out…

I always prefreeze on dry ice…its different still if u use a jacket…w jacket and prefreeze I get runny watery terps clear sugar the tedps want stick too

Prefreeze and no jacket makes the live resin look w terps that grab to the sand like thca…always run dry ice cold solvent though

Does this mean submerging the solvent tank (is it also called the recovery tank or is that different?) in a dry ice bath?

Prefreeze to -90°c liquid nitrogen? How cold is cold enough submerged in dry ice for a few hours then run on dry ice surryies what is the actual temperature you would see in practice?

Yes if u wanna cut down on the fats u could possibly pick up

I’ve had 1 extraction over 1000s come back obvious w fats after running cold…it was over a year old outdoor though thc decarb already

Let’s keep this discussion about thermal dynamics though

when the dry ice quits bubbling like crazy when u add it and acts like adding ice to glass tea …the solvent is cold as the dry ice then.

A digital temp gun can help but usually about 20 lbs dumped into 3 or 4 gals over hr will get it that cold but u need to keep adding dry ice throughout the run

Back to thermal dynamics go to the split topic thread for this for the OP

Makes sense. Been playing with this idea in my head as I want to try and get into making some HTFSE. Reason I ask, I’ve got 2 cold traps that will get down to -96c continuously and I was really hoping I could get away with utilizing these (to pre-freeze the material but also) to supercool the solvent tank before extracting, and after for recovery. Only downside is the well is 6.5” in diameter. Not sure if I can find a tank or rig that will fit.

Might have to tinker something stupid up

Yes but that will see the slurry achieve -78° with acetone in the sleeve but a material column especially a vucuumed material column would have very little convection to move latent head into the slurry I’m not saying that it is not effective for the purpose just that the interior will not be -78°

The incoming solvent will not be -78° either I’d imagine you could certainly get it cold with coils ECT but the the temperature will reach an equilibrium inside the column much higher then -78°

6 inch spool section might work, if the clamps will fit. you might end up with 4"

Do you need to use the cold trap? Ah chiller operated? Could you pump it into a jacketed spool? ln2 you could use in whatever container?

I have been contemplating having 2x tapered stainless buckets welded together around the rim and a vacuum take off installed at base

On a small scale it works, large scale you end up with poor heat transfer from the Leiden frost effect from trying to cool that much surface area/ mass. I have seen dewars that couldn’t move enough liquid into the process with the pressure builder valves wide open.