Executive Summary

Production model unit sold last year.

Alchemy Labscience develops automated industrial scale laboratory equipment utilizing our proprietary, solventless process methods, with greater efficiency than current solvent-based process equipment.

Utilizing our patent pending extraction, refinement and isomerization equipment, processes and methods inside a self-contained, automated system we bring innovative design, industry specific experience, and research and development of SOP’s.

We participate in the manufacturing and sales on cannabinoids, purchases of equipment, and funds R & D, marketing and sales efforts in trade for limited exclusivity on SoP’s and equipment distribution.

In December 2020, Jeremiah Crossett’s vision of solventless extraction technology, had manifested a prototype with successful CoA results, and was ready for commercial scaling.

- Homogenous Mixing

- Double Jacketed SS with multi zone precision temperature control

- Proprietary catalyst blend (Non-flammable, not toxic, green chemistry approved )

Technology Overview

Our technology is based on a fluidized bed reactor that enables the use of noble gasses to replace solvents and the use of surface active catalysts to replace harsh chemicals.

- Solventless catalyst driven isomerization process

- Automated w/PLC

- Polycarbonate guarding

- 316 Stainless Steel sanitary-grade

- I’m looking to make d8 and your solution seems good.

- Clean, solvent free, residual chemical free process.

- Does not require C1D1 occupancy type, does not use flammable chemicals,or solvents.

- Scale: One Alchemist unit can produce up to a 55 gallon drum a day.

- Have you already produced a machine that’s in use?

- Yes an alchemist and a hydrogenator have been sold and are in use, the alchemist unit is in Florida and the hydrogenator is operating here in Oregon.

- Experimental alchemist unit operated for a few months.

- First gen alchemist unit was operated for several months.

- I’m looking for a unit that can be moved easily and not stationary.

- Yes our units are a rolling cart, enclosed in a polycarbonate casing, are pre wired with their own breaker box ready to be connected to circuit panel, HVAC is setup to work as positive pressure displacement and ready to connect to HVAC system ducting pulling inlet air and pushing exhaust.

- Our systems are designed to function as modular, movable units.

- What price for one unit?

- Fully automated system is $150,000, however and not recommended, lower cost non automated systems can be custom built to meet customer budget.

- Can it ship to spain?

- Yes, we can assist with this, however shipping costs are separate from equipment costs.

- Have you sold many machines?

- Yes we have sold 5 units, however we had an attempted hostile takeover last year and thus had put a pause on the project for sometime, we are just getting back up and running for machine sales.

Vrilly’s Fluidized bed reactor for biopharmaceutical processes extraction, refinement, isomerization and semi synthesis of cannabinoids.

The fluidized bed reactor creates an environment where all molecules are at an equilateral temperature by use of temperature controlled gas fed into a double jacketed reactor that provides a directed heat flow, while providing a mixing factor orders of magnitude greater than any stir bar at any speed, operated under vacuum with a massive flow rate of lifting gas. Variations of this technology can be utilized for all steps and processes required to produce all cannabinoids.

The Extractor: Whole plant extraction; Stripping the raw cannabis of fractional vaporizable fluids at moderate vacuum level.

- First dewatering is performed at 80C

- Then terpenes are stripped at 120C,

- Then decarboxylation is completed at 140C.

- Delta9 THC and other low boiling point cannabinoids are collected at 160C

- Higher boiling point cannabinoids such as CBD and delta 8 THC are collected at 180C.

- High boiling point cannabinoids such as CBN and THCV are collected at 200C.

The Distiller: Vaporization and condensation driven refinement Deep vacuum system enabling the refinement of cannabinoids that have been extracted with our Extractor system to an isolated level of purity (99%).

- Highly accurate distillation driven by ultra low vacuum levels combined with high flow rate lifting gas.

- Solvent free isolate is produced by first removing co-distillates by means of fractional extraction or first pass distillation.

- Temperature controlled vaporization and condensation to optimize fractional distillation of isolated cannabinoids.

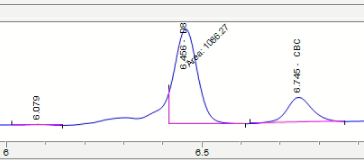

The Alchemist: Acid catalyzed reaction rotating the double carbon bond from the 6th position to the 8th position using our filterable, surface active, non toxic, food grade catalyst.

- Delta8 THC with non detectable levels of delta 9 THC

- 88.8% primary reaction without distillation.

- 98% weight to weight yield.

The Hydroganator: HHC production reactor columns.

- Pressurized hydrogen is distributed at specific rates as controlled by sensors and algorithms that never allow for a buildup of hydrogen exiting the reactor to levels that are flammable.

- Ultrasonic assisted fluidized bed catalytic reactor provides optimal hydrogenation/hydrogen saturation of bonds using safe nickel catalyst at at pressures of 400PSI and temperatures of 100C

- Higher total cannabinoids from output than the inputs fed to the machine, common rates of 88% Delta 8 THC input resulting in a HHC output of 98%.

- ASME engineer stamped

The Dehydrogenator: CBN production reactor columns.

- Pressurized air for operation at pressures of 20PSI and temperatures of 180C

- Ultrasonic assisted fluidized bed reactor

- Non metal expanded graphite hydrogen scavenger catalyst.

- CBN can also be produced from lesser known and often not tested for cannabinoids such as CBC, exoTHC, delta10THC and often results in higher purity than the input materials, eg 88% Delta8 input to 93% CBN output.

The Synthesizer : For cannabinoids synthesis such as THC0, THCP or other single point or multi point additive chemistry

- Operation under moderate vacuum with moderate carrier gas.

- Injection ports for catalysts or chemicals.

- Fluidized bed reactor for optimal mixing and temperature control to reduce synthesis time and optimize reaction purity,

Development Status

We have constructed and tested 3 prototype versions and have now optimized our design and have a commercial unit in solidworks software with half the ticket price of an available and equivalent unit. Our Equipment price is $150,000, and can be operated by 1-2 people, using around 100 amps of power. To produce a 55 gallon drum a day like our equipment does it would require twice the cost, around 10x the space and around 5 workers and twice the amps of power.

- CBD isolate to Delta-8 currently confirmed and tested Gen. 4 design iteration

- Next version available for cannabinoid conversions from delta8 to HHC (hydrogenation) and CBN (dehydrogenation)

Market Analysis

- Hemp-derived cannabinoid market

- Adult-use cannabinoid market

- Current Delta-8 and semi-synthetic cannabinoid market impending collapse due to the widespread use of solvents and lack of testing, current products contain residual chemicals unsafe for human consumption.

Equivalent Equipment Comparison

| Process Equipment | Product Name | Model | QTY | Unit Price | Ext. Price |

|---|---|---|---|---|---|

| Turbine Chiller | PolyScience 6700 Chiller Turbine | 6700 | 3 | $ 4,683 | $ 14,049 |

| Immersion Chiller | Polyscience IP 80 Immersion Chiller | IP80 | 3 | $ 4,807 | $ 14,421 |

| Dual Jacketed Glass Reactor | Across International Dual Jacketed Glass Reactor (50L) | R-50 | 6 | $ 16,990 | $ 101,940 |

| Rotovap (Manual lifting) | 50L Rotary Evaporator | SH 50L Roto | 3 | $ 8,990 | $ 26,970 |

| Recirculating Heater/Chiller | Across International C30-40 (40L) | C30-40 | 1 | $ 12,990 | $ 12,990 |

| Rotary Vane Vacuum Pump | Edwards E2M28 Rotary Vane Vac. Pump | E2M28 | 6 | $ 4,800 | $ 28,800 |

| Diffusion Vacuum Pump | Ulvac ULK-04A Diffusion Vac. Pump | ULK-04A | 3 | $ 4,800 | $ 14,400 |

| Diaphragm Vacuum Pump | Vacuubrand ME-16NT Vario | ME-16NT | 3 | $ 12,665 | $ 37,995 |

| Heating Mantle | Techno Heating Mantle (22L) | 3 | $ 6,000 | $ 18,000 | |

| Distillation | Summit Research 22L Distillation Pkg | SPD-6 FC55 | 3 | $ 14,095 | $ 42,285 |

| Subtotal | $ 311,850 |

DEVELOPMENT STATUS AND DESIGN

The commercial production unit design(s) A & B are done and product launch is underway.