genius!!!

Couldnt you impliment this to dose hard candy silicone sheets before the candy hardens?

I was thinking of ways to fill up the 50 spots before the candy hardens.

sure could @Demontrich i know a candy carter is on the table aswell

What temperature does your candy need to dwell at?

I think 300ish. I have to look at the recipe @Killa12345 sent to me

If your making hard candies. 100% they need to go to 300F

Probably kept at that temperature too. That would require a different style and lines. The od and ID would need to be increased as well.

The 1000s in stock ? Need a few

Edit:

Didn’t see em on the site

Also keep me posted on the hard candy unit as well! Will take a few

I think this filler would be great for gummy bear fills of silicone trays since the heat temp is a lot lower than hard candy.

That viscosity is higher than distillate I believe. Some one will try it soon I bet. Cleaning would be annoying unless you just pump boiling water through it to melt the sugar down. @qma I wonder if the stickyness and viscosity of gummies would have an issue around the check valves

I dump everclear in my res once it’s hot then squirt that through a few times whenI’m done. Last time w fresh batch everclear. Hot everclear should eat it so maybe you could use just hot water

I use the thompson and duke semi auto and do 8k in 8hrs filled and capped. I had tried a few different guns but had issues with more or less coming out depending on how hard you pulled. A few hundredths of a gram will really add up on a bigger scale

1000 carts in an hour seems unachievable and to hold that pace for 8 hours seems unlikely. You must be using a different filler than the one we have at our facility to be able to pump out numbers like that. You should take a video and post it because I am honestly intrigued. 16 carts a minute is basically filling carts at the speed of light. That’s 1 cart every 3.75 seconds seems impossible. When you take a video put a digital clock in the background so I know its not sped up please and thank you.

yes I use the semi auto it is much faster. I fill 20 at a time and push em down to my two people capping with drill bits

Ill post a video next time but we have been at this for a while and do 8k a day and then about two days to put them in packaging after

Damn, that’s pretty dope. We use press on caps for the carts and twist on caps for disposables. Sounds like your team is putting in hella work. Keep it up my dude!

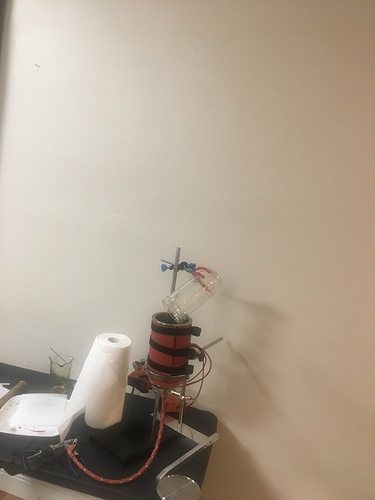

You haven’t tried my gun yet then. It is not the same as any other manual filler. There is very little variation in carts filled.

I too would like to see this t&d filler do 1000 an hour. Thats a big task for a 150 ml reservoir

Ill post a video next batch, I just keep a beaker on the heated stir plate and pour in another 150ml before its empty. Do about 1000ml of each flavor

Thats nice tho yours looks alot better then the ones I tried. Definitely alot cheaper then a t&d

Thats what we do with our Thompson. Do you use a water bath or just heat from the bottom? You should try using Mason Jars to seal in those terps!

Heat the disty to 200f and the empty beaker, weigh out disty then add terps and place on stirrer. I use 500ml beakers so its only heated with terps for 30min or so have never had any issues