I’m fully relaxed, guy.

Ya ok. Just being an asshole

50 ml reservoirs are the only ones in stock unfortunately

Congrats, you can read

Go spread your negative energy on someone else douche bag.

No worries, 50 ML will do the trick for now. Will order soon before I make my next batch.

Thank you once again

And you’re telling me to relax. Haha

Ya and calling a spade a spade.

trying to PM you

Have you ever run a Thompson Duke auto filler where your dwell and draw times are both 1.2seconds?!? I think my record was 2400 carts in an 8 hour shift. We had just gotten a new 2 ton press that pressed the caps on a jupiter cart like butter.

How do you like the bvv one?

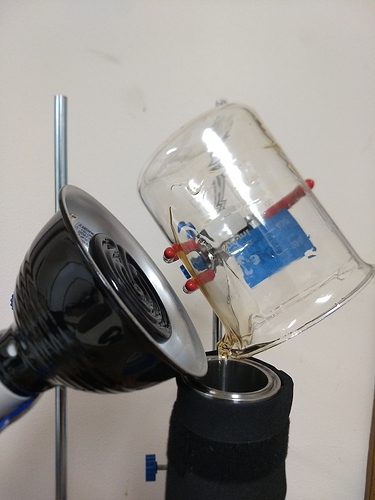

Thompson duke is finally catching up with their glass bodied reservoirs. This gun can be attached to a 1l reservoir. The reservoir can be split to service 2 guns. 2 guns in 2 hands is twice the capabilities of the duke, at 1/6th of the price (for manual) to 1/26th of the price (automatic)

Gets the job done

I’m not saying these guns aren’t amazing. That video posted above is so smooth, although that fill temp may be a little high for some of the formulations I have worked with. Save the Terps! Just the ease of the filler doing its job while you cap simultaneously cuts down on a lot of time. I cannot personally comment on price because at the facility I work for they said make more carts so we said buy another Auto filler. The thing showed up the next week.

You said your dwell time is 1.2 seconds in a Thompson duke. Unfortunately, since we are on future4200, I cannot let misinformation stand due to seo.

The total time your oil is heated is NOT 1.2 seconds in a Duke. The oil has to be heated in the rez and flow through the line.

the Duke, with its 150 ml reservoir ![]()

![]() , is not gonna work faster than a machine with 2-6 times the reservoir capacity.

, is not gonna work faster than a machine with 2-6 times the reservoir capacity.

I’m going to assume you haven’t used a Duke auto filler then. If you had you would understand that “Dwell time” is the amount of time the needle spends in your cart while the syringe is emptied. Also anyone who fills carts knows you keep your mix in a mason jar warmed in a hot water bath so when you transfer from jar to syringe there is no down time. Please check your facts before you check mine, thanks bud.

Dwell time is time heat is applied to the material.

How many times do you have to apply heat to the jar to pour it into the res? How long is heat applied from res till cart? Is there an automated way to hold the material jar or does the operator have to manually refill?

With the cart farmer desktop line, the material jar is dumped all at once into the reservoir. The reservoir is sized to facilitate easy pouring. With all machines, starting up takes longer than actually running. Making the operator switch tasks takes valuable time, hence why a 100ml res is a disadvantage.

If I were to spend that hefty amount of change (20k+) on an automated system, I would utilize a system that can preform similarly or better than the cart farmer manual. There are machines out there, like the @VapeJet for operations that require automation that have properly sized reservoirs for the task at hand, and ai features to correct errors and limit operator intervention.

I think we all know that something as simple as “Dwell Time” can have multiple meanings. When working with a Duke auto filler the setting labeled “Dwell Time” translates to how long the syringe tip stays in the cart. This is all I was referring to. We place our premixed vape solution in a mason jar and that jar is kept in a hot water bath with a temp probe so the water heats the solution to the proper temp. So heat is always being applied evenly. Therefor no need to wait for the temp of the solution to change from jar to rez. If the operator is skilled/fast enough they can pour from that heated jar right into the rez while the auto filler is still running. I completely understand the Duke is at a “disadvantage” bc of refilling the small rez but its not really much of an issue once you learn how to multitask effectively. I’m not doubting there are better solutions out there, trust me I have seen them. The advantage to the auto filler is that while its filling you’re pressing on caps at the same time, cutting down even more time. If you’re capping and filling at the same time the total time spent on 1 cart is drastically reduced.

It takes time for terps to evaporate. The reservoir acts as the “hot water bath” that you are utilizing, and the line acts as the “res” on your filler.

The cart farmer res can be set lower, from 50-70 degrees Celsius to pre heat the material for the line, which gets set 90c-boiling. The “dwell” time at that temperature is the time it takes to fill 3 cartridges.

The gun of the cf series is typically unheated, so the line brings the interior heat up to the point where it can flow into the gun and cartridge.

A liscenced operation typically needs to homogenize, and 80-90% thc pens need to have the material heated to 80-90 c to mix.

The cart farmer allows the material to be poured into the res and be totally off heat in 5-15 minutes. This keep the terps stable, since it takes time for any material to evaporate.

All the time that intense heat is applied in the cart farmer, the blend is sealed in an oxygen free environment. A skilled user can quickly dump the material jar in, and heat gun the transfer loss into the res of the farmer hands free. There is also limited oxygen exposure using this method, as both the farmer and the material jar can be filled with an inert gas like argon.

When the user of the duke applies their heat, it is enough to facilitate pouring (50-70c). The material then passes through oxygen (the atmosphere) at this temperature when poured, raising the surface area and better facilitating evaporation and oxidation (color change).