I did some thinking, my main priorities are preventing degradation of potency and material lose

I went through his thread. I’ve actually checked out his vessel before, though it was dope. My question is, without a sight glass, how can you tell if you have achieved full decarb? Just trusting time/temp? Trusting time/temp is what I’ve always done, so would I be in the exact same situation I’m currently in?

He claims pressure doesn’t lower the boiling point, its mainly to preserve terps. Now if I’m reintroducing terps, and preserving them isn’t my priority, is there any added benefit to a pressure vessel? Is the vac chamber or hot plate suitable? I can watch the oil, agitate it by moving the oil around the ptfe sheet.

That last shatter I posted, was in my vac chamber, digital heat pad on the bottom, shatter was on ptfe sheeting, monitored oil temp with infrared thermometer, it was a minimum of 250’f for at least 45 min’s. That was after being in the vacuum oven, with a minimum of 170’f, for a 5 days. Still came out as shatter. So if i cant trust time/temp, are visual ques the only measure left to trust? Without actual testing equipment of course

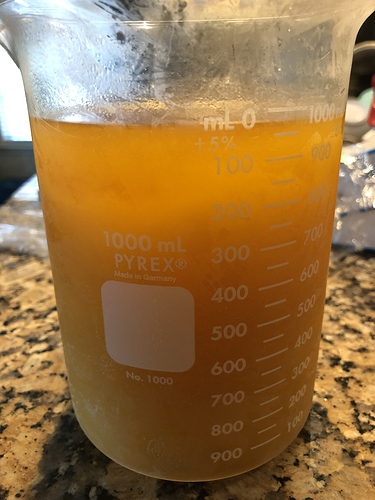

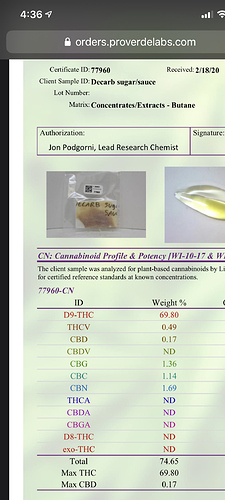

I’ve been reading that the classic “decarb chart” is kinda bullshit. It refers to hexan/oil mix on a open air hot plate. It would also make sense that not all oils are created equal. For example, I’ve read comments on here about crumble having a higher melting point and requiring longer to decarb. This orange shatter/crumble my friend claims is PHO, made with propane, maybe that’s why the decarb process is different? I had to run this oil much hotter to get an actual decarb. I had to get oil temps to over 270’f before it would actually decarb, and according to that graph, it would degrade so fast that i would lose a large amount of thc and would never reach full decarb. I noticed he set his pressure vessell at 100’c for 2.5 hours, granted, its not that hot. Should I have left my oil at 250’f for much longer, instead of increasing temps? Degradation is my main concern, I don’t want to burn off thc and lose potency.

I have been thinking about getting a ptfe graduated cylinder, I was going to use to homogenize terps and oil. I was going to wrap the cylinder with a digital heat pads to control the temp, monitor temps with a probe. Maybe I could decarb and homogenize in the same cylinder, without material loss transferring vessels?

After all, the only thing that really matters when it comes to converting thca to thc, is heat and time right?

Sorry for rambling, I never had this problem with my bho or any other oil I’ve bought before.