Thought the group would want to see a pneumatically actuated valve in operation up close. When you want to control a ball valve automatically, but with no electricity you can control them with air. Sometimes this is done because you want to mitigate sparks. The blue air line shown forces the ball valve to change position. The burst of air comes from an electric solenoid that releases a burst of air upon command from the PLC which in turn activates the valve. The solenoid can be far away from the dangerous environment. This particular valve is a spring return style. You can also get them in a double acting version from Swagelok.

How often do these valves fail to do what they are supposed to? Is it possible to have any problems with these?

Fail rate is really low. Air operated valves are the tits.

This particular ball valve is rated for over 1M cycles. The solenoid will work similarly. The upstream electric solenoid will run for 20M cycles.When working with solvents it may be desired to do your controls without spark potential. The ball valve has a leak rate of 4x10^-9 cm^3/s of helium (think fish fart every five years). This 1/4" spring return valve cost me $502.

Here is the ball valve catalog that has this Swagelok SS-43GXS4 ball valve with pneumatic control.

Would you recommend the Swagelok SS-43GXS4 valve for hydrocarbon use?

Also, fish farts every five years is impressive.

in the event of a failure would the valve fail open or closed?

Every large refinery I’ve been to uses pneumatic air for automated valves. As @AutomationGuy said hook up them up to a DCS or PLC that’s simulated/ran through a CPU. With correct sensor positions welcome to auto pilot.

Control board operators are moved up from a field operator for that unit.

Depends on the situation. They can be fail safe on either one.

figured youd be able to get either or from the manufacturer, thanks!

No problem sir. I’m not sure how much of a program wiz you are but i know @Scientific710 had some schooling with PLC programming. Y’all both are in OR.

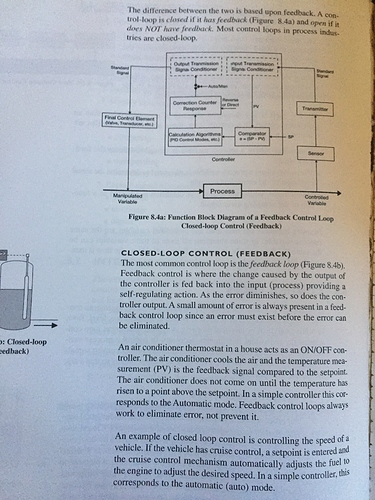

The technical name of the subject you’re looking at is called Instrumentation. It’s been a while but they have different ways to program. I think the name is called control loop feedback

To have an effective automated system you will need exact sensor locations. Remember this.

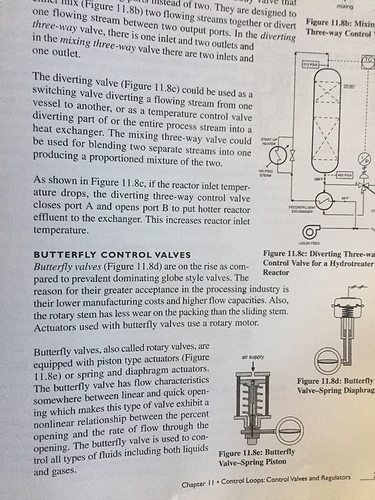

One last thing for the love of the process gods stop using a ball valve to regulate flow. They are designed for Close/Open. To throttle use butterfly valves or globe valves. Needle valves can be used in certain situations such as low pressure.

What kind of pressure sensors? Diaphragm (car) oil pressure sensors might be a bit fragile with low temps

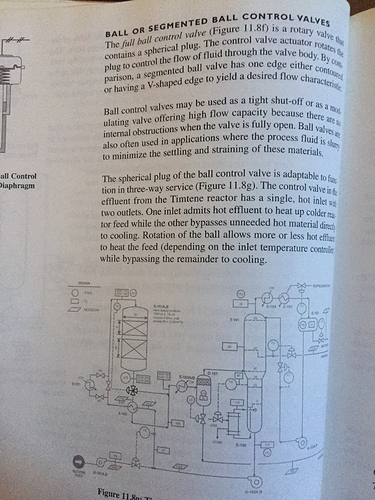

@Boogie - I recommend the manufacture Swagelok as they have any valve/actuator you would need. But it needs to be sized and of the style appropriate for your situation. The SS-43GXS4 is tiny and therefore would not do well for a slurry, but it would do well with a liquid stream.

@RockSteady - You can get these valves N.O. or N.C. (normally opened, normally closed) and spring return (shown) and double acting. That matters if you lose power (electricity or air) or something upstream fails and you want the valve to return to a specific position. In the event of a actuator (black thing in video) failure or ball valve failure (silver thing) then there is no predicting what it will do. In that case you need redundancy

@Juice311- Instrumentation relates to the sensors/readings. Control Systems and their study of Control Theory is the discipline that controlling your system would fall under. Control Loops, Hysteresis PID loops and Intrinsically safe systems are critical topics to controlling these types of systems safely.

I would also add that a segmented valve is a very nice valve for handling slurry’s and vacuum

Thank you @AutomationGuy

Your incorrect sir. I went to school for this a decade ago. I have a degree in industrial technology. One more year of schooling i could get an instrumentation tech degree. Two more years a process engineer. Tbh instrumentation tech is the one job that is need more than operators in the petro world. I know one day it will be the same in this industry.

Also depends on the application. I use a similar swagelok valve listed above as a protective open/close valve to prevent leakage/bleed through on my automated needle valve. Unfortunately mine is fail open so in the event of a air supply loss or power loss the valve fails open and can rapidly over pressurize my separator vessel. In my application it needs to be a fail close.

@Juice311 I am always open to learn new things but am not understanding what you are saying I am incorrect about? Websters defines instrumentation as “the use or application of instruments (as for observation, measurement, or control)”. Your book is titled “instrumentation” so imagine it has all sorts of instruments and neat ways to control them. The broad subject of controlling many devices (instruments, motors, pumps, etc.) to work together as a system is called Control Theory which is practiced by many, including Control Engineers, Process Engineers, Systems Engineers and anyone else that needs to make it all work together.

@achillez01 if you choose not to replace your N.O. valve (normally open), for about $100 you could replace the solenoid with a “center blocking” solenoid which would hold the valve in its current position in the event of a power/air loss. This is more of a hack, but it would buy you some time to bring your system down manually. Just note that the solenoid would release air over time because they naturally leak and your valve would go to the bad position. Send me your manifold valve bank part number and pic and I can find the part number you would need.

I apologize. That came off the wrong way. I just woke up and should have wrote that out more professionally and look into it more. I reread the question and yes the actually action of what’s going on is the practice of control theory also as you stated control/system engineers team up with process engineers. In the south we called them instrumentation engineers. I think this is a regional “slang” of terminology. That’s why it didn’t click when you previously stated that.

This is a off subject question. If you don’t mind me asking are you a industrial engineer with petroleum background? I know this is a complex engineering degree that has a wide array of industries that use them. If I’m not mistaken this type of engineering are basically the innovators of all industrial processing? Basically y’all come through to make processing more efficient?

I have a degree in Industrial Engineering and another in Manufacturing Engineering. I own SolVIS Automation which focuses on automating processes and building custom machines for manufactures. I also spend about 10% of my time consulting for owners and boards on how they can get more done for less by looking at their overall operation. But most of my time is spent designing and building cool pieces of automation. Prior to SolVIS I owned an aerospace company in southern California which I sold in 2009. My profile here shows why I am currently active on this great forum.