awesome. thank you for the resources.

however, I’m not sure why you’re going from compression to NPT then back to compression…

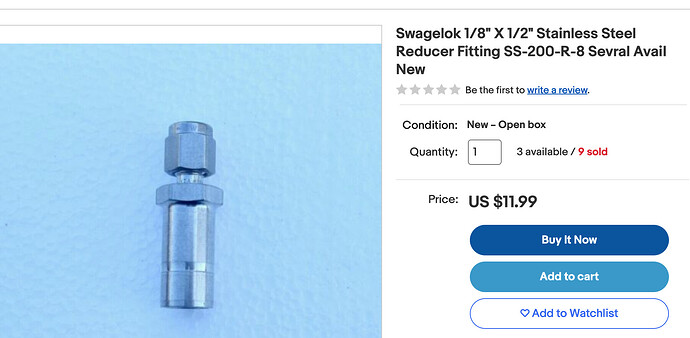

you can absolutely get these in a BT (bored through) configuration, or drill them out yourself.

you can also get creative and manufacture fittings that swagelok don’t carry…

pretty sure you’re out of luck adding actuators to the valves you’ve got. on the other hand you CAN purchase activators to go on these

you might find Low Temperature Valve automation and Pneumatically Actuated Valves useful.