Just offering a cheaper solution, and not taking a markup like some US companies do. Its called competition, its great for consumers.

Ill just be offering the steel, no support, like you claimed to do b4, but now offer lifetime support and doubled the price. People want to pay for a machine, not to pay for a dude to talk about it. Especially when theres forums like this and we can help each other out.

Did u make profit during ur bogo sale? Yes of course, so usually retail your units are double what they actuslly cost the consumer during the sale, hence the " bogo sale"

We do not “double” our price.

Our price rose because we chose to source AND weld our steel right here in the PNW of Washington, and because we chose to pursue offering FULL consultation on initial setup parameters, and continuing that free of charge FFE consult indefinitely for every customer purchasing one of our units.

I am excited for you to pursue this venture.

Unfortunately there is a lot of hidden charges running a business such as ours that you will surely be confronted with, and I’m sure this dream of “driving the prices down further” will be left in the wind.

We welcome competition, and even constructive criticisms. But just outright tantrums because you feel you didn’t get what you are entitled is too far my friend.

We put years into sourcing our steel from The right supplier, for the right price…sourcing our certified welder from the hoards of welders in the United States. And ensuring we can offer every last detail on how to assemble AND operate our units in a safe and efficient manner.

There has Always been China made parts available and even whole units provided from China companies available to anybody willing to take that risk and jump on their own. But tell me my friend, if said person is knowledgeable enough to piece their own unit together and possess the knowledge on how to run it, why would they buy from you and not directly from China? Since your steel will just be mass produced Chinese steel?

Even so We do not usually cater to those people, some want their hand held and the whole process done for them smoothly, WITHOUT a green tax. And WITH quality American Steel. That’s where we come in.

And with a lifetime warranty on our steel, and also lifetime deals on new upgrades to our systems, (including the plate condensing package we only charge repeat clients 5k for that puts our 6” unit at 180gph recovery) we feel we are in a market of our own.

The markup we offer on our units is actually less than the markup a process engineer might charge for designing/assembling a brewery, milk plant, or other relatable process equipment… and FAR less than any other American company offering extraction related equipment.

We love the forum, and everybody involved, and plan to continue offering what we bring to the industries table for the foreseeable future.

FF TEAM

I don’t think you see your fault in this ordeal. I’ll explain it to you. Tetra has been a member on here for a while and i seen what he did. Your buy get one free doesn’t seem likely from a new started company. Tetra posted fair and even was stoked at first for the deal. Than as time progressed he started poking Bc how you played it out and the likelihood was just to traffic customers to you without ever delivering the deal. He also does like this forum and what he did was just calling you on it. He seen a foul play but yet again you despised him as being a hot head customer but really he was just stating facts and wanted answers . The very least somebody to say they received this deal. I’m betting the only reason he is designing a FFE was bc of you. You created competition by not taking a better course of action on resolving the issues and the price of equipment. Than it was 100% justified in his eyes to continue when you made that post earlier where he never said a thing to you on this one. You have a young company and i hope this is a lesson you can learn from.

@Thetetraguy well i guess since he isn’t going to honor the sale or trying better to resolve the issue and you need a FFE I’ll throw all my info on this system to ya. I already know just one peice that can be changed and will make them more efficient. You have to consider these things going into this. Learning CAD & PI&D software programs I’ll share where to get. It’s a whole different world when fabricating but a journey that has its perks. Here is an example of Tri-Clover sizing.

Glacier Tri-Clamp sizing chart

sell the PI&D, building instructions, vendor list, and recommendation on engineering firm for peer review as a package. Have the firm peer review the model and customers can have there’s field tested at there facility by the same firm. NDA and watermark the pages individual for documentation. They will still be passed around but at the same time if this was sold for like 500-1000 or shoot even 2k. I couldn’t see people who was considering an FFE be that cheap and not pay the piper and saving major dough putting the pieces together themselves. This is minimal investing and headaches but still be able to make a dollar. Crumbles don’t sound to bad aye? Make sure you want to endeavor into this project. It’s a lot to go into this and the rabbit hole tends to get to deeper as these things pan out.

@downtheterphole nailed it.

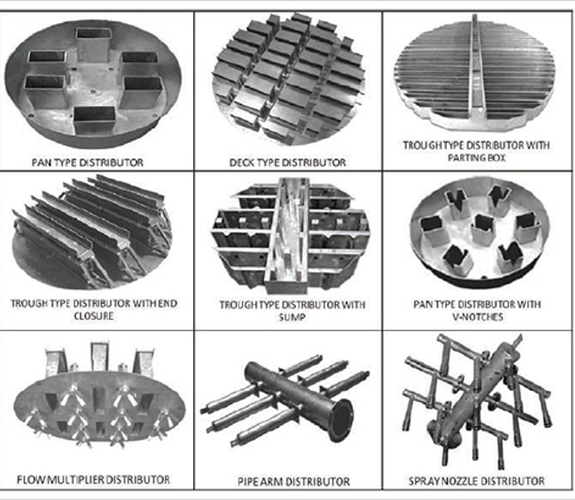

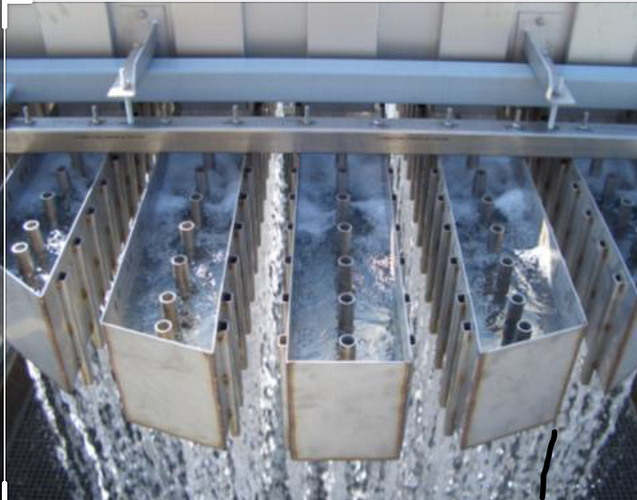

I never read this thread except the last bit last night or i would of said this earlier. They have multiple styles of weir liquid distribution. I never knew they were implanting these in design ffe. If you’re thinking about building one if these i have some interesting nozzle companies I’ll send ya way. I would think a hobbyist would have an easier day with a nozzle install than the type that’s been stated.

@Roguelab mentioned stuck crude. Wouldn’t the recommendation to feed the system with virgin solvent first than introduce crude once parameters are met?

![]() Unbelievable accusations.

Unbelievable accusations.

You “seen what he did?”

“Understand our fault”?

“A lesson we can learn from”!?

Our customers know who they are.

We have no need to call them out.

Fact is, guy was rude and didn’t get what he wanted and is throwing a tantrum.

The simple fact you claim we staged this sale to “traffic customers” in a bait and switch manner is an absurd claim and goes against everything we are as a company, and if you have followed us here you would see that.

We’ve always promoted DIY and always will, so we’re kind of missing the arrow over here…

Distribution plates are great, We offer raised evaporation tubes on our units as well as distribution plates on upgraded models…

We always recommend pursuing Plate condensers as well… just source sanitary dismantling plate condensers, not brazed sealed condensers…

![]()

![]()

![]()

Thanks, im not great at fabricating/welding steel myself, but i do have a great connection to people who can make most anything from a drawing, im well versed in graphic design, so making 3d models of what i need wont be too hard, if i ever have to go down that route.

Im also not in need of anything that is red tape friendly, im going to be operating under “prop 215” still.

Y’all crack me up.

dosent look open source to me.

Spammin?

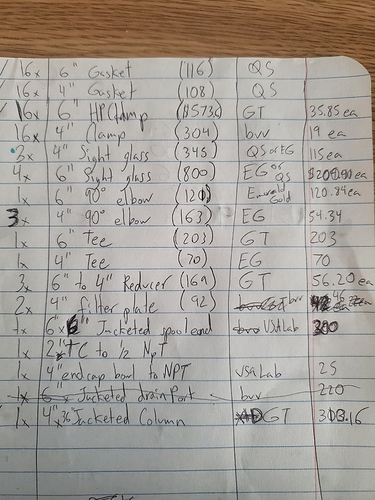

Heres a price list, if anyone wanted to try and find cheaper parts or whatnot.

Bvv is best value vac

QS is quality stainless parts

EG is Emerald Gold

GT is Glacier Tank

My SS cost is at 9.3k right now

1.2k for the rack and clamps (got lazy here)

200k btu Closed Loop Hydronic heating system is 1.7k

So far im at 12.3k

Im going for 30 gallons/hr to start

Where’d you find that image of all the different distributors?

Google search “Weir liquid distribution” and look under images. These type of overhead feed distributors are commonly used in packed/fixed bed columns/towers.

Keep in mind vertical FFE will be obsolete by next year if not two years. Horizontal FFE works off of spray nozzle design and are superior to vertical design. Im sure one of these companies have stepped up there game and have been exploring this route. The interchangeability of horizontal far outweighs vertical. Also they have more than one type of tubing for higher surface area contact.

Membranes will replace ffe

People want to save the terpenes

You think mass solvent recovery will be done through membranes? It seems more economical to have solvent recovery done through a evaporator and the last ass end of degassing go through membranes. I would think the cost of the membrane filters, cost of full membrane solvent recovery unit, and time to recover wouldn’t outweigh an evaporator.

Evaporation is expensive and destroys one of the most valuable parts of the plant (the terpenes)

Membranes separate solvent for about 20% of the cost

Then If you’re warm extracting and winterizing with a membrane you’re saving even more on energy and eliminating a big bottle neck for most (chilling solvent)

I’ve seen what membranes can do, they can take a black extract and make that shit look like disty WITH the terpnees in there

Crystallizing CBDA would be possible with membranes since you could skip distillation.

This gives you atleast 13% more since its cbda

Membranes arent that expensive if you know which vendors to get them from

Just wait and see, were going to be implementing this at ExtracTech on 25000 pounds of hemp a day to start

I have a master list of them all. I know there are alternate routes with membranes other unit style. I was looking at these 7 months ago for final degassing.

If terpene capture is one of the goals LPGs should be the solvent. The evaporator seems the easier route since the lowest terpene is 116. Than run membrane after.

Now flip side due to the output amount you’re implying that doesn’t seem reasonable so your going heptane. With the boiling point of heptane vs LPGs i see the advantage doing this as a full post process recovery/filtration

Why not have an automotive style fuel injector to feed each tube? I think their flow rates are controlled by pressure regulation and pulse width which could be automatically adjusted by reference of a vapor pressure sensor on the output, before the condenser.

Boiling point doesnt matter when you evaporate under vacuum though

Butane takes 10 less btu to evaporate then heptane

It’s not much

So you know which water filtration membranes work to separate solvents?

Why are you saying they’re expensive then?

I’ve been picturing the same thing. I’ve got an aftermarket fitech system on a hot rod and the tech is very approachable and inexpensive. I’m not sure it’s “food grade” tho.

This is called the flashpoint. I’m not 100% knowledgeable of membrane filtration but i thought a noble gas pushes while having a vacuum on the other ends.

By expensive i mean the continual changing of membrane filter media. How often you have to replace and how much does one of these cost for the system doing 25k of biomass a day?