use a condenser instead of a compressor for vapor recovery

I don t have the electric capacity for that option need to evaporate 1000kg of butane a day

I am all pro passive recovery

But the treuth is at a large scale it s not used often used

Look at the oil and gas industry the will have their reasons

Thats alot of gas to recover. A large shotgun condenser, id have to do some research for the best option for that much gas and that strong of a pump. Is lpg a option for heating

Yes I now heat with propane on a home heater wich in turn heats the jacket and internall coils of the collection pot

Don’t dismiss the wizardry of @downtheterphole

Have you seen the new yellowstone FFE? His condenser is super interesting…

add a bit of pressure and bring that condensation point to a better place

I find it a waste that we lose the cooling power of the evaporating butane and

And have to chill the outlet gas of the recovery unit

Since electric power is a bottle neck I try to merge them

That sounds like a riddle ![]()

Ad pressure by means of temp ?

A better place as ?

Hemp seed press cake has 18Gj/kg. Use it to power steam engine that will run power generator. Green energy ![]()

Find me a off the shelf steam generator that runs on propane that isn t super big and I am buying

I need only a 100kg of steam an hour

I think I follow…

If you apply heat to a vessel to evaporate butane, where is the cooling power at? I know that evaporating butane will consume power from the heater, but is something getting cold somewhere too?

Isn’t it just less heat?

If you don t apply heat to the evaporating vessel it freezes up lowering its internal pressure making the compressor suck void space

The cooling power is at the exaust of the compressor before the solvent tank to lower the pressure of the warm vapor

On a 300L collection pot I need to heat with 8kw to keep the solvent evaporating at a temp of 40C or 2.7 bar

I could probably do with less kw if my jacket and coils where better designed

And gave a better heat transfer

Now that is interesting !!!

Brand ?

Seifert. German brand. This unit is possibly still for sale as the guy selling it didn’t have any offers on it. I can DM you his number.

The reason there is so much solvent involved is that crc teck works best. When the solvent go s treu at a slow speed for not having to wait i want to have enough for 10 runs in a 8 hour shift (or more) and let recovery take place continuasly ![]()

Another plus. For this closed loop of heating and cooling is that since the chances of breaking down are nihil

There isn t much danger

The compressor outlet pressure is 16 bar. If the inlet is at 2 this is deu to friction heat when compressing

Since all my power comes from generators and I find 16 bars a lot for my 6" tri clamps I try to kick out all that can break down and this seems like an option also the fear of the heaters gooing haywire making the exaust pressure even higher or the chiller dying half way

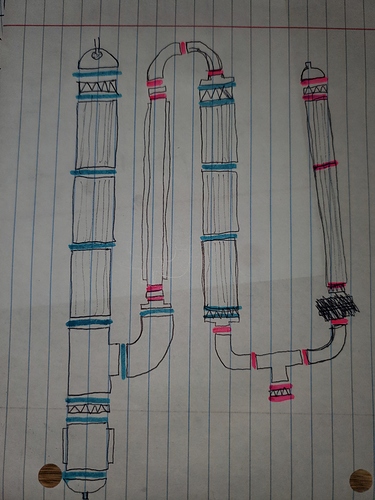

U gotta find your exhangers (two 6"x36" and one 4"x36"), but heres the part list and little diagram for the FFE ill be making. My estimate dimensions are 64" tall and 54" wide.

Part list:

16x 6" High Pressure Clamps & Gaskets

16x 4" High Pressure Clamps & Gaskets

3x 4" Sight Glasses

4x 6" Sight Glasses

1x 6" 90° elbow

4x 4" 90° elbow

1x 6" Tee

1x 4" Tee

3x 6" to 4" reducer

2x 4" filter plates (big holes)

1x 6"x12" jacketed spool

1x 4" x36" jacketed Spool

1x 6" spray ball/cap

1x 6" endcap bowl to npt

1x 4" endcap bowl to npt

My heat exhangers:

6x 6"x12" shell and tube

1x 4"x24" shell and tube

1x 4"x12" shell and tube

Everything can be sourced from glacier tank, xtractor depot and quality stainless parts for under 8k. (This is pretty much falling formulations “27k” retail unit with an extra 4" condenser)

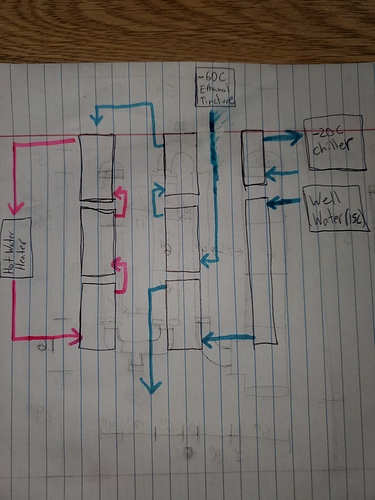

Heres my diagram for the heat/cooling flow