Y’all crack me up.

dosent look open source to me.

Spammin?

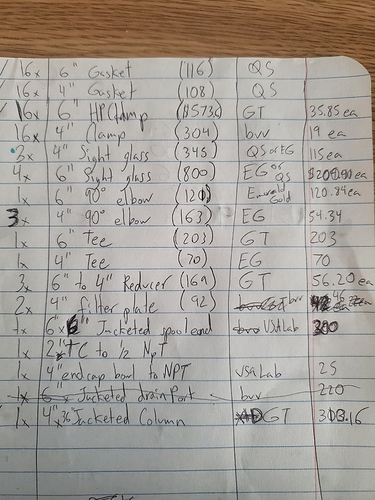

Heres a price list, if anyone wanted to try and find cheaper parts or whatnot.

Bvv is best value vac

QS is quality stainless parts

EG is Emerald Gold

GT is Glacier Tank

My SS cost is at 9.3k right now

1.2k for the rack and clamps (got lazy here)

200k btu Closed Loop Hydronic heating system is 1.7k

So far im at 12.3k

Im going for 30 gallons/hr to start

Where’d you find that image of all the different distributors?

Google search “Weir liquid distribution” and look under images. These type of overhead feed distributors are commonly used in packed/fixed bed columns/towers.

Keep in mind vertical FFE will be obsolete by next year if not two years. Horizontal FFE works off of spray nozzle design and are superior to vertical design. Im sure one of these companies have stepped up there game and have been exploring this route. The interchangeability of horizontal far outweighs vertical. Also they have more than one type of tubing for higher surface area contact.

Membranes will replace ffe

People want to save the terpenes

You think mass solvent recovery will be done through membranes? It seems more economical to have solvent recovery done through a evaporator and the last ass end of degassing go through membranes. I would think the cost of the membrane filters, cost of full membrane solvent recovery unit, and time to recover wouldn’t outweigh an evaporator.

Evaporation is expensive and destroys one of the most valuable parts of the plant (the terpenes)

Membranes separate solvent for about 20% of the cost

Then If you’re warm extracting and winterizing with a membrane you’re saving even more on energy and eliminating a big bottle neck for most (chilling solvent)

I’ve seen what membranes can do, they can take a black extract and make that shit look like disty WITH the terpnees in there

Crystallizing CBDA would be possible with membranes since you could skip distillation.

This gives you atleast 13% more since its cbda

Membranes arent that expensive if you know which vendors to get them from

Just wait and see, were going to be implementing this at ExtracTech on 25000 pounds of hemp a day to start

I have a master list of them all. I know there are alternate routes with membranes other unit style. I was looking at these 7 months ago for final degassing.

If terpene capture is one of the goals LPGs should be the solvent. The evaporator seems the easier route since the lowest terpene is 116. Than run membrane after.

Now flip side due to the output amount you’re implying that doesn’t seem reasonable so your going heptane. With the boiling point of heptane vs LPGs i see the advantage doing this as a full post process recovery/filtration

Why not have an automotive style fuel injector to feed each tube? I think their flow rates are controlled by pressure regulation and pulse width which could be automatically adjusted by reference of a vapor pressure sensor on the output, before the condenser.

Boiling point doesnt matter when you evaporate under vacuum though

Butane takes 10 less btu to evaporate then heptane

It’s not much

So you know which water filtration membranes work to separate solvents?

Why are you saying they’re expensive then?

I’ve been picturing the same thing. I’ve got an aftermarket fitech system on a hot rod and the tech is very approachable and inexpensive. I’m not sure it’s “food grade” tho.

This is called the flashpoint. I’m not 100% knowledgeable of membrane filtration but i thought a noble gas pushes while having a vacuum on the other ends.

By expensive i mean the continual changing of membrane filter media. How often you have to replace and how much does one of these cost for the system doing 25k of biomass a day?

Maybe somebody smarter can tell us why they’re not doing it this way yet😜

They last a year as long as you dont foul them

The membranes were using do not evaporate the solvent, it seperates the solvent basically the same way an RO filter filters water except at a MUCH higher pressure

https://doi.org/10.1016/j.mee.2008.12.009

https://sci-hub.tw/

What equipment would it take to do this?

Not sure about metal membranes

We have a membrane expert on staff who’s custom building us some ceramic membranes

Were just waiting on the ceramic

He use to build membranes for the wine industry I guess

The higher pressure doesn’t increase the temperature?

@CCCBD

They have spray nozzle that won’t accept pass a certain psi. You would need a rotometer that is controlled loop to an automated butterfly, globe, or needle valve. If your going to try to control feedback this with pressure and heat this will be more complicated. you will need to know your parameters inside the column but self adjust the other process variables.

These units are temperature controlled.

They have a chiller that keeps the solution cool so it doesnt evaporate

Hello,

We want to know the price diffrence depend on the evaporating temperature of the alkohol at reduced pressure.

200l capacity of alkohol per hour, alkohol evaporation temperature 40 and more . Plese give me 3 possibilities in all sets (chiller heater,pump and everything) .