Im brand new at this and dont want to wreck my system. I have a large coil and running passive and wont be able to get solvent around without nitrogen. I need assistance ant suggestions welcome

What exactly do you need help with? Adding nitrogen to a system is super easy. Pressurize your solvent tank w/ N2 - assuming it as a dip stick, and you’ll be on your way.

EDIT: Use the search tool, this topic has been brought up quite a bit.

When you finish injecting solvent, you’ll want to release the N2 from the solvent tank into the atmosphere w/ a check valve. You do this so your tank is no longer pressurized and you can recover your solvent. If it remains pressurized itll be almost impossible.

I was having trouble dialong in my regulator it starts off pretty higj i was worried about flooding my tank with nitro and ruining everything. This eill be my first run . I will be distilling my solvent for first time today. Already have dry ice and iso and material. I have an issue with that as well. They put anti sieze on one of my ports and i need to get the residule out. I used iso and cleaned as well as i could

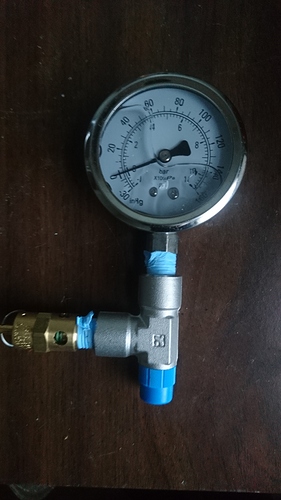

You can buy regulators that only go up to 60psi

Dude, you really need to your the search tool, do some reading … this exact question has been asked numerous times.

what problems were you having with the regulator? There are 2 gauges on a regulator, the one closest to the tank valve shows you the tank pressure. The other one will show you the working pressure.

Tank pressure stays the same, whatever psi is in your tank will show on that gauge when the valve is open

The working pressure gauge will change based on how far you turn the regulator.

Rule of thumb when working with regulators, keep them off when not in use and back the regulator adjustment handle off entirely to ensure no pressure is put on the internal parts.

This is what I do for the most part -

- Ensure the regulator is OFF and tank valve is CLOSED

- Connect line from regulator to solvent tank vapor port

- Connect line from solvent tank dip tube to top of column

- Open the tank valve, observe you get pressure on the first gauge (my full tanks are around 2500psi)

- Slowly turn the regulator to open it and begin sending N2 through the hose

- Increase until you reach desired psi (i start at 20 and slowly bump it up to 40 by the end of the run)

- Open valve to material column to get things started

- Open valve to vapor port on tank to let the N2 in and pressurize the tank, sending more solvent through to the column

- Once solvent tank is charged, close the vapor port valve. (from here you can shut down your N2, or leave it sitting if you want to bump another charge towards the end if pressures drop)

To shut down the N2 system

- Close all the valves (including tank valve)

- Close the regulator valve (note you will still see pressure on your gauges)

- Disconnect lines to N2 tank (this will release pressure on the working gauge side)

- With the tank valve closed and lines disconnected, open the regulator again to purge the tank side of the regulator. Both gauges should be 0 at this point

There are other things to consider like venting the N2, but it’s been covered in great detail in other threads. I’d recommend reading over those and they should get you more comfortable with the process.

And lastly, if you don’t have PRV’s on your system it would be a good time to invest in them. N2 can cause some serious damage to your equipment if left in the system with hydrocarbons and the temp rises. There are some pics on here somewhere of a solvent tank that completely buckled from N2 pressure because of this happening. Can’t remember who posted it, i think it was @Killa12345

Thank you so much. I have prvs. I appreciate it. This is my first time running. I get the idea of everything and i read but rather be safe and sure… Check, check, and check again

I have an extremely large coil and tank. For small system

4×48 dewaxer

25lb solvent tank

My collection only holds about 12lbs pf solvent

Upgraded my sieve as well. I know its going to take a bit more n2 to push the solvent through material and coil. How do i know ive got all n2 out of system without losing hydrocarbons

If you get your collection balls cold, it will prevent the solvent from producing much vapor at all at those temps, so you can safely vent your collection until it gets close to 0. Your solvent will be pulling a slight vac at those temps though so be careful to not let it go below 0 because it will suck outside air in.

I don’t run with dry ice lately so I’ve just been burping before I start recovery. I have a line hooked up to my collection pot that goes outside, so I just vent that until it gets to like 2-5psi and start recovery.

Where are your prvs? I don’t see any pressure relieve valves on your system. You’re gonna want pressure relieve valves on your gauges above the columns and on the gauge on your collection pot and the solvent tank gauge or else you risk a big ol’ kaboom.

Have prv on solvent tank 150 psi. Will take picture im heading back to the shop rn. Presssure tested again yesterday. Sieve pressure dropped a little nothing else budged. My buddy unicorn theory is going to make sure i dont take the neighborhood out. All recognition to him and everyone on here for posting. Could never have built this without you.

U probably should add a prv to the top ur column and collection, the solvent tank also but u have it done. Essentially anywhere that u will isolate it w nitro In the system

Yes definitely going to. Bought some. I asked for 75psi they gave me 150 so i gave it to my buddy for his solvent tank. Have to head back to hfs sometime this next week and get some and some more T fittings

150psi would be fine. And probably a great set point.

I see 60-80psi running nitro crc. 75 psi prv would pop

No crc yet on this rig looking at w1 though