that be sorcery of which most don’t retain the will of understanding, teach them you may great whizard

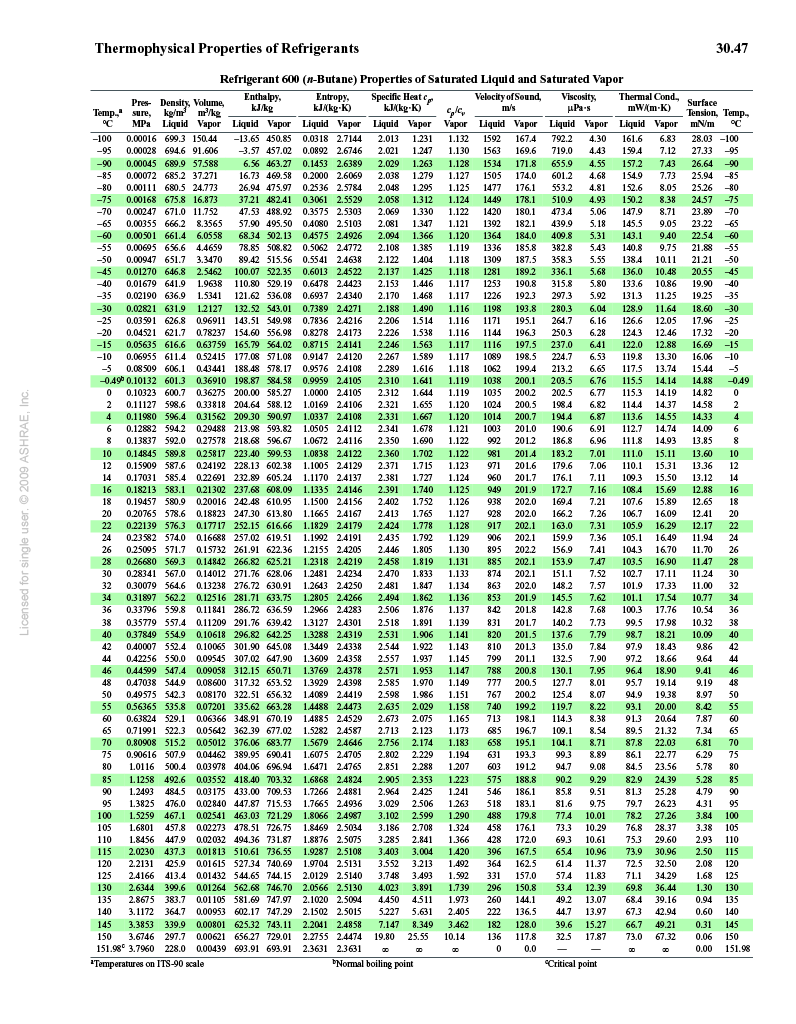

Then the place we start is Butane - Thermophysical Properties

Where we find the latent heat of vaporization, which is how much energy is required to go from liquid to vapor (and the amount you need to remove going from vapor to liquid).

Which is listed as 386000 J/kg

=> 92.2 calories per gram.

Let’s imagine OP used “a can” aka 300ml, which the engineering toolbox tells us has a density of about 580g/liter at 20C

So that’s 0.3x 580 => let’s call it 175g of butane in that can.

To evaporate (or condense) that 175g we need 92.2calories per gram x 175g => 16135 calories.

How much 50C water is that?!? (Imagine 50C=> 30C)

Resource: The calorie and the food Calorie

16135/20C => ~800ml

(Because an calorie is the energy required to raise 1g of h2O by 1C)

Of course that’s ignoring all the heat losses to the environment and stainless.

Well, technically speaking… if he is subliming the butane he would need a significant amount of calories vs simply boiling at a higher pressure. Below -138.3c is pretty cold to be running the basin at!

?!? What did I miss?

I was just coming back to note the additional thermodymagic that makes that “20C x800ml water temp drop” work faster if you go from 80C to 60C

To sublime it must go from a solid to vapor.

Similar to how dry ice sublimes into vapor.

…and when would our OP have been dealing with butane as a solid?!?

At 20psi butane boils/condenses at: 24c (0.239 MPa)

At 10psi butane boils/condenses at: 14c (0.170 MPa)

To go from Gauge pressure to Absolute pressure take what you see on the gauge and add 14.7psi to it. (14.7psi = the weight of the atmosphere at sea level)

To go from Absolute pressure to MegaPascals (MPa) divide the Absolute pressure by 145.038.

I don’t have a water pump I just kept add hot water to it.

There are a number of things here that need to be addressed.

First each isolatable pressure vessel should have both a pressure gauge and a pressure relief valve. After that there are a number of handy YouTube tutorials that already exist for operating a small scale Extractor like this.

Based on your information it sounds like somewhere along the line you let a bunch of air into your system and it’s presence is preventing your passive recovery process from proceeding.

To give you good instruction we would need to know more about what system you are operating.

Thank you. I did not vacuum the hose. That was probably why

Unlikely. volumetrics don’t make sense.

Might be informative, and Bret has other videos on the subject.

I personally believe folks should start with ethanol…you can even use the same gear.

better…

@GCFFiltration is correct, it’s easier to provide assistance if we can see exactly what you’re playing with.

We need a couple or five 1k word substitutes so we are all on the same page.

If you are having to move lines around like the video above, I suggest you give us a hand drawn diagram of the various stages.

Vac down. Solvent addition. Recovery.

@WolfeXtracts is also in point. This trick can kill or maim…and has repeatedly.

That’s a pretty good video, with some misinformation, but all pretty harmless. We feel like he could’ve better explained how you vacuum down your system, but ultimately it’s a decent video.

We like this instructional up until he tells you to vent your solvent tank and vacuum the butane atmosphere out of it. A vessel that has only solvent(liquid and atmosphere) in it will be under vacuum if it is cold and empty enough.

So our only adjustment to the video we’ve just shared would be don’t vent the tank, just put it back on dry ice and wait about 10 minutes for it to vacuum itself down when it condenses its own atmosphere. Additionally, only have the appropriate amount of solvent in your solvent tank(which should’ve been vacuumed down completely before it was ever filled with any solvent) if you intend to empty it completely into the system as this instructional advised.

Again a little bit of misinformation, but most of it fairly harmless.

I was gonna post this

How he vacuumed the system down is actually one of the things I was doing wrong. Then I saw this video and saw that he vacuumed it down to the hose going to the tank with the tank off and I YELLED DAMNIT SERIOUSLY!!!

I think I have enough solvent for one last run but they are in separate tanks. Is there a way I can transfer one to another tank even tho both have solvent in them?

Absolutely, but if you can’t figure out at least two different (vapor or liquid) ways of doing that, you should probably sit and ponder it for a bit rather than have someone else hand it to you.

The drawings I suggested you do earlier might help.

Passively comes to mind. You should definitely familiarize yourself with the concepts a bit further before you go much further so you can be sure you can deduce the solutions when problems arise.

Moving solvent from one tank to another is always going to be a matter of pressure differentials when you’re not using a recovery pump.

Recovering solvent is a form of distillation. ![]() . A recovery pump is basically like using a vacuum pump on a still; Helps assist the speed at which you’re recovering your solvent and speeds up the process but is not needed.

. A recovery pump is basically like using a vacuum pump on a still; Helps assist the speed at which you’re recovering your solvent and speeds up the process but is not needed.

I would look into jackets and the ½" recovery lines if you want speed.

Too soon?

We are still working on the basics here….