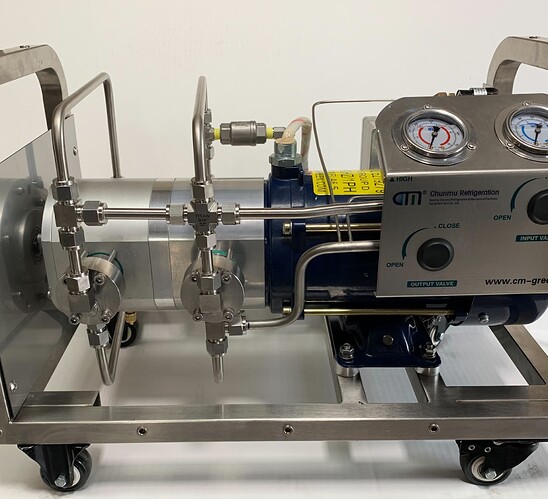

Item Model/Manufacturer:EcoGreen Industries, Dual Pump Conversion Kit for CMEP-OL compressors

Description:Change your CMEP into a 4 cylinder pump

Price/MSRP:

$1200 for kit only

$1800 for EcoGreen to rebuild your current compressor and install the Dual Pump Kit

$2199 for refurbished compressor with Dual Pump Kit

$2699 for new compressor with Dual Pump Kit

Current location of item:In Stock at EcoGreen Industries

Estimated lead time: In Stock

Fulfillment: Ships directly from EcoGreen

User support / Warranty: 30 Day warranty, covering any defective parts or manufacturing

Link: EGI DUAL PUMP CONVERSION KIT

EcoGreen Industries would like to introduce the new EGI Dual Pump Conversion for the CMEP-OL compressor. While developing the EGI Dual Pump Conversion kit, we talked to our customers and listened to their needs. We used actual customers for testing and feedback, not perfect environments, and not ideal conditions. Together, with their feedback, we developed this kit and made a couple improvements for flow and reliability. It doubles the size to 2.5 CFM, features an all-sealed design like the CMEP-OL for safety, and adds a pressure return line with check valve to relieve internal case pressure. The EGI Dual Pump Conversion kit uses all common pump assembly parts from the CMEP-OL, and no specialty tools are required. It also retains the quieter operation of the original CMEP-OL compressor. Increased reliability comes from the all-new non-toxic Tungsten Disulfide grease used in the crank bearings. Included also is the EGI High-Flow Kit. This helps to keep output temps down a little and increase flow to help maximize the pumps potential.

• Almost 1 CFM larger displacement than other conversions on the market.

• More operating time between overhauls than other 4 cylinder compressors on the market.

• Remove choke points in the vapor flow path that other conversions leave.

• Uses less energy than two single compressors.

• “Case Pressure Return Line” or “CPR” Line relieves excess vapor pressure from inside the case of the pump and returns it into the input line via a 1psi pressure check valve.

• Uses the same internal parts as the CMEP-OL, reducing costs to the customer.

• The “All sealed design” of the CMEP-OL is maintained, unlike other conversions and 4cyl pumps.

• Retains a lower operational noise level just like the original CMEP-OL.

• The custom shaft and conversion plate can still be used on a single pump compressor if for any reason it was needed.

• “New” Non-Toxic extreme temperature grease with WS2 additive has a very low coefficient of friction and an extremely high drop point temperature, which means longer run times and a higher grease separation temperature than what the compressor operates at. This is used in all crank bearings for extended life now at EcoGreen.

We aren’t going to throw a bunch of numbers at you that claim any certain recovery speed. We all know that companies typically choose the most ideal conditions to get the best numbers to post to customers. Instead, we actually used customers and did real world testing. And we didn’t use customers that get long run times, instead we used customers that go through pumps quickly and are very hard on them. We wanted to know if they saw a significant difference when using the Dual Pump Conversion, and the answer every time was YES. Like us, their biggest concern was the longevity of the crank bearings, a problem that has always plagued the CMEP-OL. We found that the lubrication itself, the grease, was falling short and needed improving. We researched and tested different grease before finding a combination that actually made a significant difference in performance. We now use a High-Temp Non-Toxic WS2 grease in all the crank bearings. The separation temperature, when the semi-solids separate from the liquids, is over 3 times higher than the working temperature of the bearings themselves. This high working temperature in the grease, along with the extremely low friction amount, makes this grease far superior over others used currently. The WS2, or Tungsten Disulfide, is FDA approved for use in food processing and pharmaceuticals manufacturing. It is inert, non-toxic, and non-corrosive. We tested 10 different Dual Pump Conversion Kits, and already have some out in the field being used. We are now seeing customers that are extremely happy with the faster recovery rate the Dual Pump Conversion Kit gives and are also experiencing extended times between overhauls. We include the EGI High-Flow Kit to help maximize the pumps potential for flow. It also runs about 5%-10% cooler on the output line when using the High-Flow Kit. It was our customers, and the feedback that we read here on Future4200 that really got us thinking about a really good conversion kit and actual fixes to the problems the CMEP-OL had.