Hoping to have a scientific discussion on Methanol Extraction process. Take a look at this write-up, I’m looking for feedback on the merits of the subject, please dont reply to yell and scream in fear of Methanol. Methanol ACS or Reagent ACS processed correctly could be a cost effective extraction process. Your thoughts? Sorry if this is redundant to other threads.

Lots of polar crap comes out extracting with methanol but no lipids. Makes for a gross extract unless you use another method to remove sugar and chlorophyll like LLE with an alkane

with the still involved, you’re recovering most of the solvent. which makes the “but it’s cheaper” less persuasive. you then blow the remaining solvent off to atmosphere, which is when yelling and screaming about methanol might be appropriate.

190/200 proof food grade ethanol QWET in large glass or stainless container/vessel> single 5 micron filtration > green mixture to RotoVap or other vacuum assisted alcohol distillation unit> take oil obtained decarb until all bubbles gone. RSO.

If you have high grade material the ratio should be 7 grams of bud to 70ml of etoh should make 1gr of rso.

Thank you for all the replies, but I’m looking for a discussion if Methanol can be used safely in an extraction process. Do others here use Methanol washes instead of QWET? Does this leave residuals in the final RSO. Is the third step effective in removing all Methanol if the oil is boiled down to no bubbles?

Not all. We use MeOH in process and even decarb’d we sometimes see upwards of 300ppm residual unless we vac purge. Absence of bubbles isn’t sufficient to indicate res solvent for class II solvents. That being said, the Class II permissible is 3000ppm so if you’re okay with that, you might be alright. We don’t want any fallout so we aim for an ND with an LOD of 60ppm

The best way to be sure all meoh is removed is distillation. I wouldn’t use it as a solvent unless the crude (RSO) was bound for distillation subsequently

I don’t have a big problem with it as long as there is very good validation for the purging procedure and/or it is for oral/topical administration. The USP 467 limits are good enough for me but I never want to be in a position of guessing if my oil is below the limit. Distillation obviously addresses that.

@SidViscous Well isn’t methanol undigestable? Isn’t food grade 190proof ethanol just the safest for rso. Like aren’t we also supposed to have all the chlorophyl and shit left inside of it.

I’m not sure exactly what you mean by undigestible but the word “toxic” comes to mind. Mostly the blindness being the concern. Absolutely, making RSO at home with EtOH or even IPA/acetone are preferable. I was only talking about extracts being made with methanol in the process, which there are many reasons to do. IMHO, solvent cost is not a good reason to opt for methanol. However, its relatively high polarity and immiscibility in alkanes makes it very useful for applications other than RSO. There are also people here who have to distill their own ethanol because it is not available in their countries; it would be a mistake to not discuss the safety considerations of making extracts using methanol in the hope that people would not use it as a solvent, because clearly it would not be a sufficient deterrent.

Hi Sid,

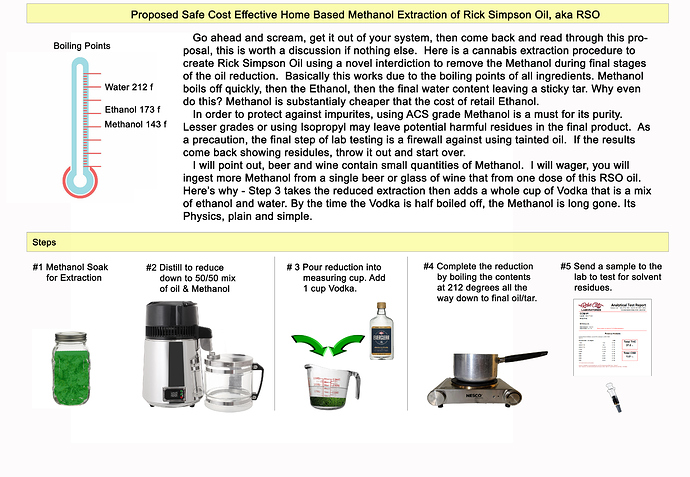

Thaks for great comments. I am an end user and do EtOH all the time, and am happy with that, but the cost of retail 190 proof is unreasonable - $75.00 a gallon. Moonshining would be fine, if it were legal here in the States. Licensing to produce it as ‘fuel’ alcohol is another costly option, but keeps one inside the letter of the law. This leads to the middle ground of using a legal source of certified pure Methanol ACS reagent as a solvent source, thus this discussion on how to devise a process that will create clean extract at the home level. Of course, Methanol is a toxic alcohol and all safety measures should be used in its handling. I’d like to continue this discourse towards that end of creating a home-based refining process without huge investments of gear, such as a vacuum purge system. The goal is to keep this safe and within the means of a home user. What I proposed in the graphic above is close, and you added to this with great input above.

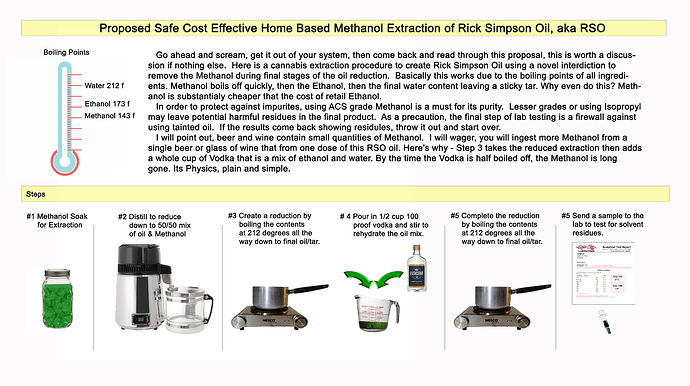

So, for sake of discussion, lets break down step three into multiple steps. The first is to boil down the Methanol wash into non-bubbling oil (very tar-like) . New step, add in a 50/50 water/ethanol mix (100 proof vodka will do) double the volume of the oil, stir to mix into re-hydrated state. Then, boil off this new the mix back down to the non-bubbling oil. Has anyone done anything along these lines?

Also, maybe you could answer this question. Using either EoTh or MeOH, when the solvent frees the cannabiniods from the plant, do they ‘chemically bond’ or is it a true ‘dissolve’ where the two are miscible but separate? I’m afraid of the former, wanting the latter. With no bonds to break, the above second re-hydration and reduction should result it better that 60ppm.

Oh, BTW, last week, I got a quote from a chemical supplier for a 55 gallon poly drum of Methanol ACS for $281.00, less than $6 a gallon!

That’s over complicating everything for the “end user” especially if you’re simply aiming for rso. The “end user” will still need some kind of a heated vaccum chamber to purge the methanol out unless you get testing done to prove all that extra LLE is getting it to acceptable ppm limit.

-Someone correct me if I’m wrong

With food grade etoh based RSO it’s literally safe to ingest after just the decarbing process because it’s etoh not methanol ![]()

![]()

![]()

![]()

I mean maybe you could settle for heptane denatured if the cost is too much. I see “people have success with it” and “customers can’t really tell the difference” a lot on here and I also read “the cost isn’t decent” on here a lot. So that’s soemthing to look into maybe. Idk I never used heptane denatured

Here’s what I’m thinking. I’ve expanded this to have two reductions, first to boil off the Methanol, then the second to boil off the Ethanol/Water mix. This would drive down the Methanol ppm to near zero when the water boils off.

Now you would think this, but it’s not usually the case because the oil if not dissolved any more (which is what happens when all you have is trace solvent and water left) is too viscous to give up the goods easily. At least this has been our experience

Again, you’re over complicating it. Use straight up ethanol or heptane denatured.

You could use a heating mantle with a splatter platter for reduction.Ethanol Diamonds? - #53 by GroovyOctopusLabs

You’re adding another step trying to save money, but it’s going to equal out the same when all is said and done IMO.

Thank you all for the feedback. I’ve got 6.5 oz and a gallon of Methanol ACS ready to go, will share the test results when done. I’ll do step #1, a MeOH wash, then divide the wash into three equal parts. Then do three separate tests from #2 - #6. At #4, First test will be 100% water, 2nd test will use 50/50 water/ethanol, and third test, 100% ethanol. Gonna spend my pandemic unemployment on lab test results! Doncha just luv Scientific Process? ![]() Better than sitting at home on the computer!

Better than sitting at home on the computer!

Some people seem scared off by the heptane, but it’s very hard to end up with a detectable level of heptane in an extract made with 5% heptane denatured.

The heptane is the first thing to boil off via the azeotrope. During R and D I had one test come back with almost 100,000 ppm ethanol, but heptane was below limit of detection.

Good luck, let us know how it goes. I suspect you will have the best luck with the straight ethanol but that will probably defeat your reasoning for using MeOH in the first place.

One option that would probably work well is to boil off the bulk of the methanol and then reflux in EtOH for a long while with the reflux line just at the top of the column. That will keep the oil/alcohol micelle liquid and allow the MeOH to escape without having to dilute a shitload with ethanol.