Looking to step into the emulsion world and wondering if anyone knows of a good consultant or is a consultant themselves that would be willing to sell their services or SOP’s. DM me please

High or low energy nano emulsions? Do you have any specific requirements regarding formulation?

Hi there,

We are selling a new machine we have been developing for a few months here.

It comes with basic SOP’s.

I will post the PDF here for it.

sonication.pdf (3.8 MB)

Spray Dryer offered as well, these two products go hand in hand with making water soluble powders.

Please email Rab@ldt-works.com for pricing and detailed information.

We have clients across the US using these machines to make products in tons of retail locations.

Not limited to the cannabis/hemp industry, we have extensive petrochemical/brewery experience, our clients beer is EVERYWHERE including Disneyland lol. ![]()

![]()

Spray Dryer.pdf (1.3 MB)

Low energy, and I forgot to include that the emulsion would be used for flavored drinks and syrups so we wouldn’t need full translucency. We would eventually be moving into edibles as well.

Happy to help if you haven’t found a solution yet. Just sent you a message

Use vesisorb, its oil based (no noisy loud equipment) and its the only nano that’s had legitimate third party lab studies done to prove effectiveness.

Theres no magic in low energy nano emulsions, your surfactant system will have the biggest impact. Ultra pure polysorbate 80 works well, as does TPGS and PEG 400.

In low energy systems, the surfactant ratio is key to low particle sizes, agitation second and heat third. PH affects overall stability.

Here’s a basic low energy nano water soluble SOP for you:

- Heat a volume of water, 80-90% of total solution (rest is surfactant and cannabis oil), to 50c, buffer water to a pH of 3 using citric acid. [example would be, 100ml for 10g of surfactant and oil solution]

- In a beaker on a heated mag plate, combine surfactant and cannabis oil along with a suitably sized stir bar, homogenize at 800 rpm until well combined and also reaching a temperature of 50C

- Once both solutions are to about 50c, begin slowly adding water to the surfactant/oil (organic) mixture under high rpm, use as high as you can remain stable with. Add water as slowly as you can bear, use a programmable peristaltic pump to assist.

- This process seems to be important, although you can simply dump the water into the organic solution, there is reason to believe that interfacial tension occurs when slowly adding water, leading to better droplet size.

- After your water and oil phases are combined stir for ~5 minutes or so or as long as desired. More is not likely to improve particle size as the majority of the action happened when the water hit the organic mixture.

For best long term stability of the nano emulsion, filter solution down to 0.2 microns and store refrigerated.

Thats pretty much it. More surfactant to oil will create better nano emulsions at the cost of poor flavor; for that reason highly recommend ultra pure polysorbates.

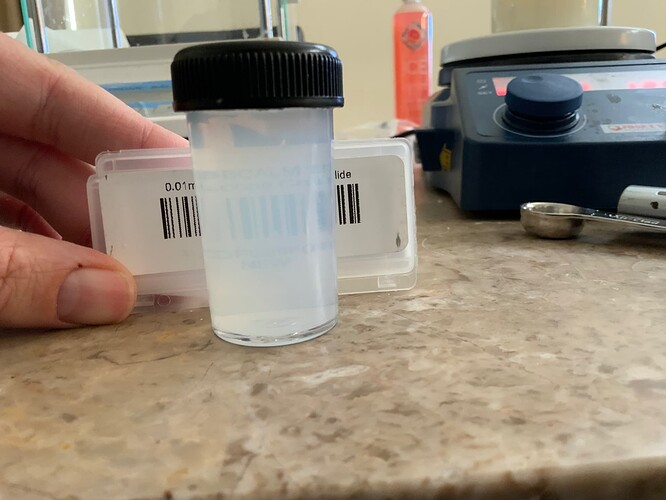

These were done following the basic steps above with poly 80 and TPGS as the surfactant system, surfactant to oil was 2:1.

For grins and giggles, I ran a series of tests while I was bored after finishing up an experiment on low energy, i decided I’d stick some solution in my ultrasonic bath and see what happens.

It would turn out that placement mattered a great deal and the first few sessions through the bath likely had minimal effect due to the spacing of the cavitation of ultrasonic waves @ 24khz. As a result, I do not believe I had my solution in a spot to receive significant energy for completing the emulsion until later on, this was observed by the color changing dramatically around the third session (running 10, 10, 10, 30, minute intervals).

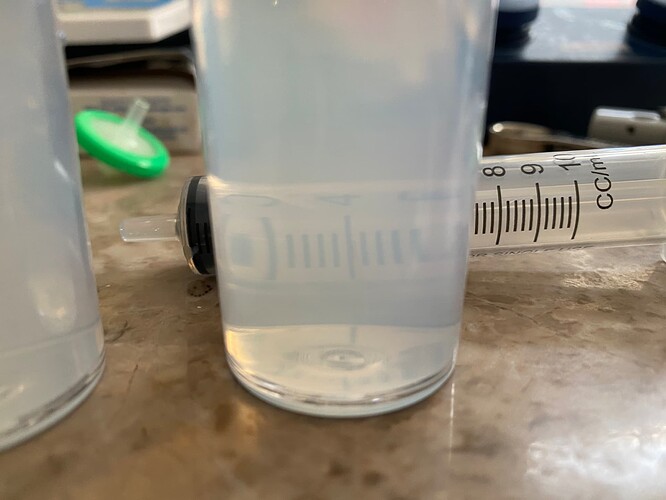

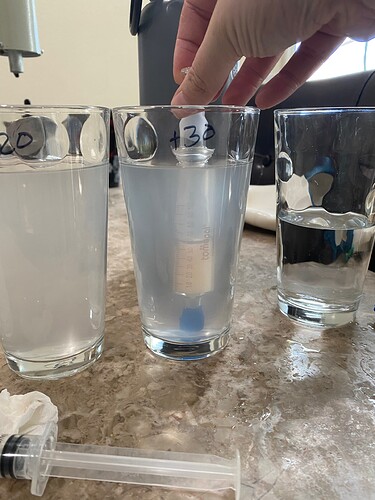

Left: low energy stock solution. Right: same solution after 60 minutes sonication.

20 minutes and 30 minutes in. I believe placement was the biggest factor here, encouraged by this I let the glass syringe roll around the ultrasonic bath for 30 minutes while I did other stuff.

After letting it roll around for another 30 minutes in the ultrasonic bath, the transparency is in full effect.

Each glass contained 1ml of solution (you can see actually going from 30 to 60 minutes, 1ml is removed). Taste is pretty atrocious but you don’t need such a high SOR for ultrasonicating.

I gotta open my mouth wide for that spoon. I know you were using percent and ratios but I’m assuming time mixing and volume are related? What volume would you say those measurements are for and how would you scale time to volume? Or is it more of a visual aspect?

Edit: I do see the 100ml to 10g now my bad

From my understanding of low energy spontaneous nano emulsions, time spent agitating is not so much a factor, as the mechanical action that creates the nano particles happens when the surfactant meets with the aqueous phase creating a kind of intermediate that has a high surface tension, achieving the effect.

Although I can’t recall specifically, my inclination was that the studies I had read showed no significance difference in particle size in those that mixed for 24 hours and those that mixed for 5 minutes. Rather, surfactant system, ratio, and method execution seemed to factor into the success of the method.

Unfortunately I lack the equipment to adequately measure the particle size and distribution to specifically hone the system down (my next lab addition if I can find an affordable solution).

Are these reasonably shelf stable, or just the reasonable agitation before consumption?

The stability of the emulsion in this state will depend largely on storage temperature, colder being more stable. Overall stability, regarding agitation and such, will depend more on the final recipe.

Can this be used for drinks or just edibles? I’ll have to do some research, thanks for pointing this out!

Highly recommend using a sonication device for shelf stable beverage mixtures.

High shear will produce encapsulated cannabinoids down to roughly 0.5 microns to 0.3 microns in size.

Sonication methods produce encapsulated particle sizes down to 0.03 microns

This may not seem drastic, but you WILL notice onset differences in how fast your body can process these compounds in your gut/liver, between the two product particle sizes.

You will also experience much better shelf stability in products with 1/10th the particle size, as the smaller particles must recombine nearly 10 times more before they are even near the size of the particle size of the high shear produced particle size.

How high have you seen your concentrations get with low energy methods prior to introduction of sonication?

I’m curious how maximum solubility compares between high and low energy methods, as my experience is mostly ultrasonication. I’ve done 10-20mg/mL cannabinoid concentration without trouble but I’ve gone up as high as almost 50mg/mL with some extensive sonication and some modifications to the surfactant system and overall formulation with a few other additives, is that similar to what you’ve seen with your low energy experimentation?

Also, I can confirm that low energy methods rely much more on temperature changes or interactions with the surface tension during phase inversion with the addition of the water phase to the oil phase. Your understanding is accurate.

I only bring this up because if @Smblue is going to be dabbling with this for his applications, it’s important to consider the end product and how it will be formulated. I’m not saying one method is better than the other (high vs low energy), but if solubility differences are noted, knowing the amount of excess water that may be added in the final product to hit your target cannabinoid/dose value, this is something to consider.

I also have access to particle size analysis at pretty much no cost, if you’re in Michigan let me know and I’d love to help get some of your stuff analyzed if you’re curious about particle size until you get your own equipment set up.

Can Eric with Soluscience chime in on this subject?

Also Kinematica is a good company if they are on here still, they do this stuff with equipment

smaller particle sizes doesn’t exactly mean its more easily absorbed.

there is a “sweet spot” when it comes down to emulsion particle size.

Any literature you can drop on this point?