Oh you’re gonna love the pour spout

Exactly! The more surface area allows more evaporation instead of creating a bottleneck of not being able to use your pumps to the highest efficiency. Once I’m into the bulk or recovery the pressure in my base and recovery tank is usually only 10psi with my TRS running to my high pressure tank and 1 K&F running venting back from the recovery tank. If I add my second K&F it will drop it down only a couple of pounds more and only speed the overall recovery time to maybe 2.25 hours with only 12" of surface area of evaporation available. I did tilt my pot at a slight angle (25 degrees or so) one time to see if increasing the surface area for evap would help and it did speed it up slightly, but I couldn’t get enough of an angle to add much more surface area. . . . but with bizzybee and precision both going vertical could also have had to do with the fact that getting certifications are a lot easier with smaller diameters for pressures, and it makes a much smaller footprint!

Like this?

he only runs a lb material at time and don’t recover though,

I thought maybe he runs to much gas? ![]()

I swear man I thought this was a reply from @Soxhlet cause he’d pull that kind of smart ass reply too.

I was being serious in way 12lbs solvent to 1lb material seems a lil much to me

I do run up to 12 lbs of solvent on a fire pack, ballpark yeilds in the high 20’s

Ah, the good old square-cube law:

“When an object undergoes a proportional increase in size, its new surface area is proportional to the square of the multiplier and its new volume is proportional to the cube of the multiplier.”

What this means is if you take a shape like a collection pot and double its size, the new surface area will be 2^2 or 4 times the original and the volume will be 2^3 or 12 times the original shape. This has substantial consequences for heat transfer applications in industry and the biomechanics of life (large animals/jacketed process vessels have a much harder time cooling down vs small).

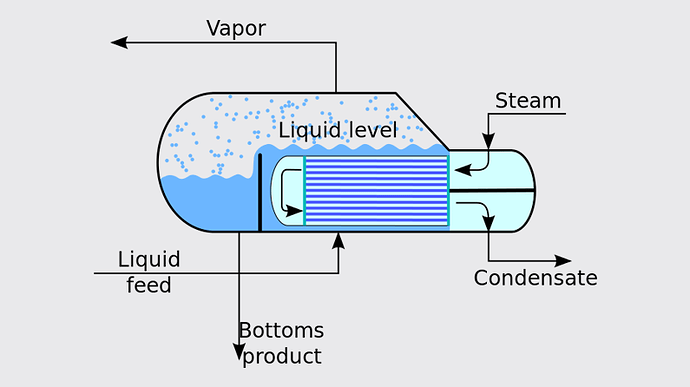

I think Xersist and Homesteader hit the nail on the head. Applications that have a large need for vapor, like an entire house or a gas-fired water heater (or a large extraction system) all use a horizontal tank because it has a larger evaporative surface area than the same sized tank oriented vertically and therefore can supply more vapor.

Does anyone remember when Future was testing his V1 FFE and he was trying to run the tankless water heater from a skinny, vertical tank? I believe he ran into vapor supply problems due to lack of evaporative surface area, just like Xersist describes. For a large application like that, even if you crank the heat way up on the skinny tank you will still have vapor supply problems due to lack of evaporative surface area. That small circle of exposed LPG at the top of the liquid pool can only release so many molecules per unit time.

Another way to look at this is if you’re recovering butane from a 12" pot and your heater is sufficient strength so it doesn’t lose temp during recovery but then you change to a skinnier pot which has a higher surface area-to-volume ratio due to the square-cube relationship and use the same heater/temp to attempt to recover the same volume of butane and it goes faster, that means you were too inefficient at getting heat into the 12" pot to fully take advantage of its evaporative surface area. I’m a big fan of internal heat exchangers, especially with larger vessels made from thicker steel required for ASME.

In extraction, I think an issue that most of us face is that we are typically trying to heat/vaporize LPG that is already at or below it’s boiling point due to the low temps used for extraction. Assuming someone extracts at -40C, they are already right at the BP of propane @ STP (standard temp and press.) and well below the BP of butane (0C). Depending on what gas you’re extracting with and how your system is setup, that large difference in BP can dictate collection pot size/shape. With subzero butane you are often trying to add sensible heat to raise the temp of the solution and also trying to stay ahead of the latent heat demands which makes things slightly more difficult than propane which has a much lower BP.

I see most people who are making extracts for dabbing using around 80-90F on their collection pot to preserve terps. Keep in mind that the temperature of the LPG/oil solution will be dependent on the vapor pressure inside the vessel and the chance for degradation really only exists towards the end of recovery. With a significant mass of LPG boiling in the pot, I think the heat on the collection pot and any internal heat exchangers could be significantly raised to around 110-120F or maybe higher (150F?) to increase boiling rate and then lowered to our accepted 80-90F towards the end of recovery. This may require a source of cool water that is separate from the hot source in order to cool everything down quick enough to avoid degradation.

I’m also planning to experiment with some different preheater configurations, probably using a tube-in-tube exchanger similar to what the Bizzy team uses on their FFE’s and for the exact same reason: boost enthalpy before vaporization.

this post is full of good information.

you’re on the right track.

I use a jacketed coil before my crc to attempt to bring the solvent up in temperature before filtering to make the powders more effective, I did notice an increase in efficiency when recovering and I am sure if I had another or possible tube in shell exchanger that the effectiveness would be increased

I know that you are a fan of the hydrocarbon falling film evaporator and I’m guessing that’s what you are hinting at by saying I’m on the right track.

I agree that for the fastest throughput, a tube-in-shell evaporator would reign supreme.

For making crude with hydrocarbons, whether active or passive, I definitely think that a tube-in-shell evaporator makes much more sense than a giant collection pot like BHogart or Purge labs use.

I mostly make dabbing oil and live resin. I also usually have multiple different batches of varying size to get through in a work day. Some batches are really small others large. Would it make sense to run a 3lb batch through a FFE sized to handle the 70lb batch coming up next?

IMO, it is much easier to have multiple collection pots on hand than multiple FFE’s to facilitate my needs and I’m willing to sacrifice a little recovery speed for that perceived ease-of-use.

I was also a little unsure about how CIP would work out with a FFE. For running multiple flavors of live resin I would need to be sure the evaporator is completely cleaned out. I can’t have even .5g of that gassy GMO contaminating the fruity zkittles batch coming up next. I understand the CIP procedure would be to cool the evaporator and flood with clean solvent. This would take time and also the solvent that was flushed through the evaporator would need to be recovered from the jacketed receiver like a standard collection pot. That would also take time. I’m thinking I can open a collection pot and clean it out in a comparable time to getting a FFE cleaned and ready to go again.

I wouldn’t be surprised if someone who is well versed in FFE operation, like yourself, has these issues all sorted out. I am used to batch, pot-style recovery so I decided to stick to that for my system upgrade mostly because it’s what I know and it didn’t make sense to spend a bunch of money switching FFE which may present other unforeseen issues.

Like I said, for large scale crude where there aren’t multiple batches that need to be separated I would be on team FFE all day.

you can attach as many collection pots as you want to a falling film evaporator. batch separation is trivial.

cip just run hot pressurized solvent. this is multiple floods or a quick rinse, depending on system design.

Right I dont understand why you would cool it down to clean it

Now that the Bizzybee999 IG account is active again, thankfully, I’m looking at his butane FFE posts and it looks pretty clearly that both the upper sight glass and the area around the spray nozzle/distribution system gets coated with oil. I would imagine flashing/splashing is happening much easier in these areas with butane versus ethanol no matter what type of distribution system is used.

It also appears that the lower sight glass and I’m guessing the lower 1/3 of the evaporator tubes become completely coated in thick oil as well.

It really looks like it would need to be taken apart and have certain areas hand cleaned between batches to get everything spotless. Either that or the volume of liquid solvent that would need to be flushed into the collection and then recovered in the traditional batch style would be excessive.

For live resin it really needs to be spotless between runs.

@Apothecary36 I was thinking the evaporator would need to be cooled somewhat before/during cleaning to avoid need to flush too much liquid through, which would need to be recovered batch-style. You would still need to keep it somewhat warm so oil didn’t full solidify on the inside. I would really hate to have to clean each tube in a tube-in-shell by hand.

any residue stuck in an ffe is due to geometry issues in the design.

warm solvent vapor keeps it very clean internally.

or make your ports long enough to pour/clean/reset. without ever removing them.

Good point but line might hang up or come loose. To risky for me

I’m trying to get away from larger diameter clamps / ports.

Anyone using smaller diameter tube(s) positioned horizontally as a collection, like 4" - 10"dia?

Why are the tall skinny mfg like bizzy not positioning their collection horizontally?

The evaporative surface area gains are immense.

I am small scale I think. but I use a 12 x 12 collection and run a full 20 lbs butane per run on 2 - 4 lbs biomass. When people run the 6 incher is it used with a pump actively so that you can run 20 lbs tane through the column? Ive had this jacketed 6 incher but never used it because its more clamps and hemi reducers to buy. it does fit nice in an igloo cooler and its jacketed too so it could simplify things. I have a trs 21 too so i could do recovery and extraction at the same time i think? Im homeless but maybe i should post a craigslist ad in michigan to extract?

I like mine proportional to the size of the storage tank .

More for safety reasons

I tried asking this same question and making this same point earlier in the thread. I don’t believe I got a real answer from anyone.

The efficiency of the collection pot (evaporator) is usually the limiting component of recovery speed IMO even though lots of people think it’s active vs. passive. I think it really boils down to evaporative surface area and how well you can get heat into the solution. They have dealt with this same issue in industrial distillation applications.

I think some people tried increasing the evap. surface area but suffered from decreased proportional heat flow into the solution (square cube law comes into play big time if you’re only using a jacket) so they ended up with worse overall recovery speed. This led some people to falsely conclude that skinnier pots with less surface area are more efficient and faster.

I take it you’re aware of Bhogart’s horizontal vessel design, correct?

It would seem to fit the description of what you’re trying to do. There should be some used ones out there somewhere for cheap.

That’s one thing I do give that company credit for is that horizontal evaporator design.

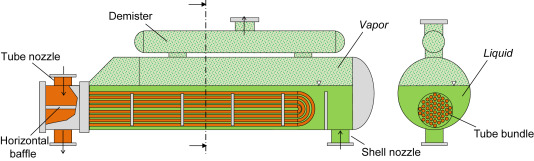

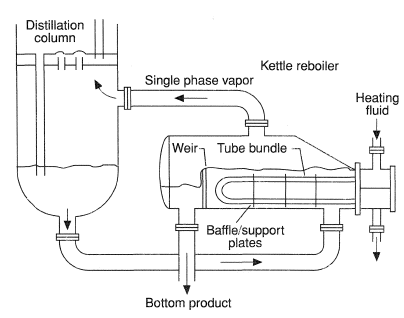

If they would have taken it one step further and made them into kettle reboilers I think they would have hit new levels of recovery speed. The half jacket on the bottom is ok but very far from the best way to get heat into the solution IMO.

Kettle reboilers pretty much just have a U-tube sheet jammed into the bottom of the horizontal vessel. They are used in industrial distillation setups to reheat the bottoms product and send the vapor back to the column.