Thanks.

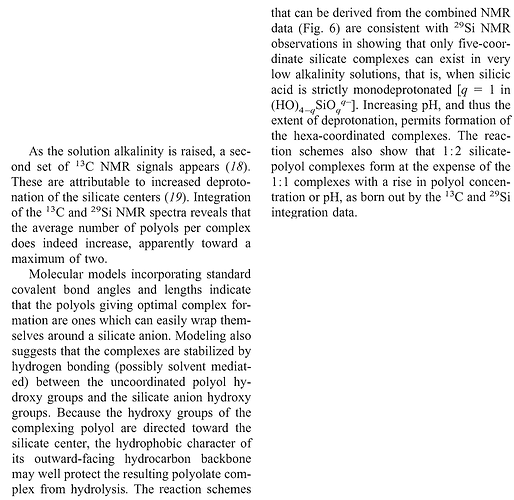

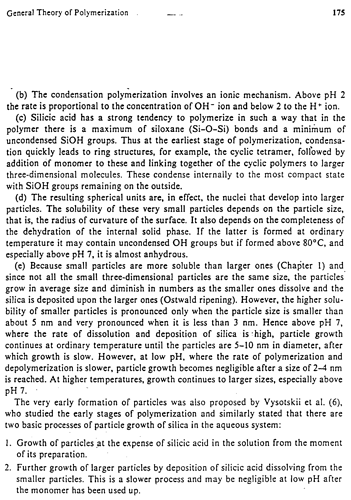

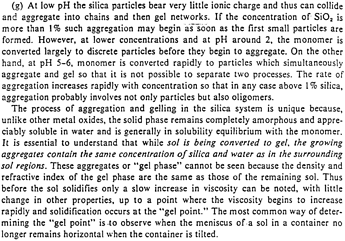

I assumed that adding dilute acid (e.g., 0.01M sulfuric acid or 0.1M phosphoric acid) to the dilute silicate solution (i.e., basic silicate solution into DI H2O), reducing its pH to ~1.5, would convert the silicates in the dilute silicate solution to silicic acid. And then, adding the stabilizer (carnitine HLC or sorbitol) while maintaining a pH of <2 (low alkalinity) would form hypervalent five-coordinate silicate complexes with the silicic acid. With reaction scheme showing a 1:1 silicate(silicic)-carnitine complex (or 1:1 silicate(silicic)-polyol if using sorbitol).

Maybe using a pH of 4 or 5, low enough to convert silicates to silicic acid and reduce the alkalinity, during the mixing process (before adding the complexing stabilizer) would yield a better result than a pH of <2.

In contrast, if we add the stabilizer to the basic silicate solution, which has high alkalinity and increased deprotonation, hexa-coordinated complexes should form, providing increased complexation stability. But in that case, reaction schemes show a 1:2 silicate-stabilizer complex. And I assumed once we drop pH to <2, the hexa-coordinated complexes formed under high pH and alkalinity would reduce to five-coordinate complexes due to silicic acid being fully monodeprotonated at low pH and low alkalinity.

In other words, I assumed adding acid before the complexing stabilizer (converting silicates to silicic acid) and adding acid during the addition of the stabilizer (or pre-acidify the stabilizer solution), would provide a similar result to adding acid after the stabilizer. But, instead of complexing silicates (hexa-coordinated) under high pH, which then convert to five-coordinated silicic acid complexes when we reduce pH, we would form the five-coordinated silicic acid complexes up front. And provide a better end product. Because I assumed when we reduce the pH of the hexa-coordinated silicate complexes (at a 1:2 ratio), the transition to five-coordinated silicic acid complexes (and 1:1 ratio) would result in some incomplete silicic acid complexation and/or incomplete conversion from silicate to silicic acid, along with putting free stabilizer in solution.

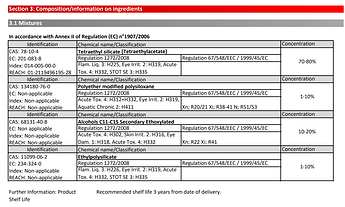

I don’t think it matters if we add the glycerol after the acid and stabilizer, but I could be mistaken. Because from what I read over the past few days, glycerol, PEG, PG, etc., mainly function as humectants; they don’t directly stabilize or improve the silicate complexes.

Please remember that I’m not on the same level as you, you’re a trained chemist, and I’m not. So, some of my assumptions may be comically incorrect. Try not to LOL too much ![]()

![]()