You should definitely go DTF imo. Once you pick inks/colors you can’t change as a fyi.

What do you guys think about the LX610? Built in Die Cutter is pretty cool. https://www.primera.com/lx610-color-printer-cutter-config.html

We have it, its finicky on occasion, but it has a pretty good print quality.

We tricked I into working without proprietary sticker paper, the ink is pricey and it sucks it down

The downside also would be the ink seems to have no UV resistance, so it’s terrible for stickers that see daily wear, or UV.

I haven’t looked into if that’s an ink or paper issue.

Good quality, but you can’t currently get chips to run non oem ink for that model. The LX900 is the only model that I’m aware of that you can get chips for.

The Epson 15000 and Silhouette 4 combo is legit. I got both on eBay for under $500 last month (making offers worked better than I expected) and finally got time to seriously dive in and I’m blown away by the quality, price notwithstanding.

There’s a $30 software alternative if you know how to use Adobe Illustrator or Corral Draw but the free Silhouette software looked fairly robust. I’m able to run significantly thicker paper than the specs (120# cover so far) by carefully manual feeding. The bulk sublimation kits are available on eBay for ~$35 plus ink.

If you’re looking for a budget solution, you can’t go wrong with this combo, even at the $650 it will cost you new. There is no sacrifice on quality either, this printer could output studio quality prints.

Hell yeah agreed 100% a print shop in every lab let’s goooo

Seriously… Once you hit a certain size it obviously dosent make sense anymore, but for the small to medium guys, in house print and creative will save you 4-5 digits a year.

For product labels, we’re using the Epson CM3500. Not the fastest, but great for small production runs. If I continue to grow, going to look at some of the bigger Epson label products.

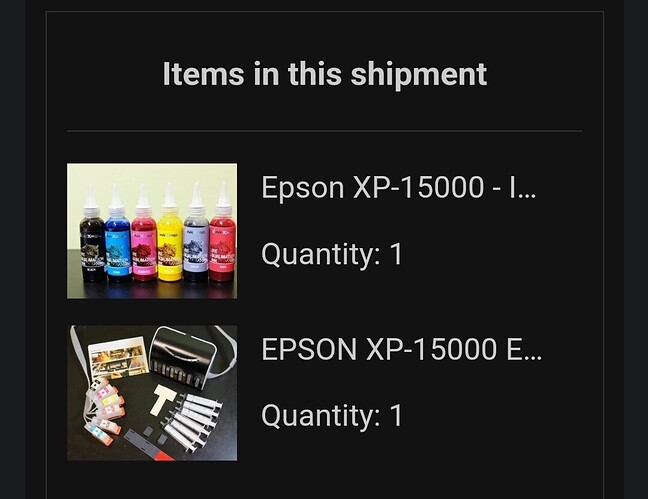

Got my ink kit for my xp15000 today excited to try it

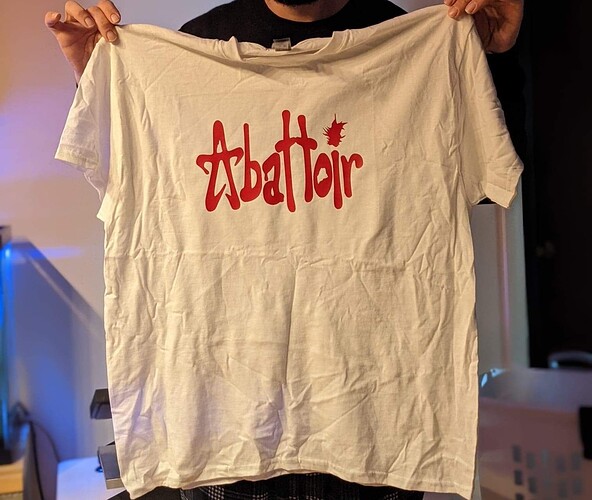

Old printer

New printer

Huge difference

Shoutout @ky_cbd for helping me

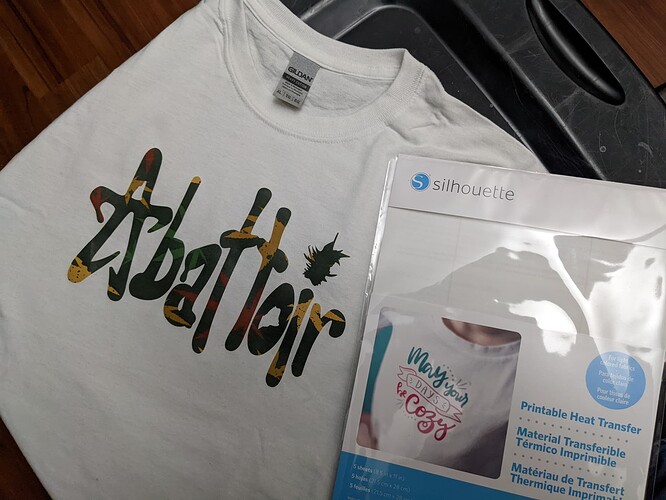

Made some tshirts. Brick vinyl. Came out pretty good. The faint square was just from the heat press and went away. Been through the wash a few times and held up great. Bonus if your cutting with a cameo.

What heat press do you use? I’ve been window shopping them for a while now can’t decide whether it’s worth it to go for the commercial style or just the silly little desktop cricut one

My instincts tell me it’s worth the extra couple bucks for a serious duty one

I was the exact same way… I wound up getting the heat press nation black series 9x12 platen. First ever heat press, so nothing to compare to, but I like it, and it works good, and has even heat.

I bet a rosin press could do breast logos on a polo or hat…

I want to try doing some rolling trays on my rosin press ![]()

Was this sublimation by chance?

Beautiful either way

I’ve been kinda wondering about sublimation for logos on shirts, I just hate that you have to use polyester instead of cotton

If you get DTF ink you can transfer to anything. And your printer is setup for white and varnish. Sublimation is definitely lack luster…

I used heat transfer vinyl. It just has a application layer that you weed your design/cut out of, and a heat activated adhesive. I’m waiting for some printable stuff in the mail.

I honestly really REALLY regret not getting a 15000. Cause I most definitely would have rolled DTF(Direct to Film) first. You can transfer the prints off the film, or just print onto vinyl and laminate it(labels)

That tray is beautiful!

You said the printer can only run 1 ink type correct? I already got the sublimation ink, I haven’t installed it yet though. Can DTF ink be used for regular printing like labels and such or does it only work for things like heat transfering things on to a t shirt?

Considering going dtf if it can do regular print, you might have just saved my ass man

If you really want a media you can laminate your DTF ink into vinyl.

I would just print my labels, apply them, and leave a no media/paper… just ink label. Look up DTF Labels …you can apply them to a jar just like a Tshirt

Shits the hawt tech. Costly at scale too… boutique shit.

Probably the most work I’ve done hacking a logo apart to make it easier to weed. Just cut it and still can’t weed this bitch easily. oh the joys of vinyl and things we do for family ![]() @VoodooExtracts1 I’m tryin bahaha

@VoodooExtracts1 I’m tryin bahaha