I would like to learn the advantages of grabbing each individual cart to fill. I thought people just held the trays up to fill this style machine

You can do it either way. I’ll send you a video on what’s app later today.

I have the 1000 cart farmer and was looking at your fully automatic and saw this but I honestly would think that this would be slower than my cart farmer.

@calmcbd it is entirely up to the operator, your oil, how hot you want to get it, how big of a needle you are using, how fast you can fill without overflowing the sidewalls, etc. etc.

This is a foot-pedal operated unit, not a hand-operated unit. The pumping force comes from a motor, not the users hand. We use N2 displacement in the reservoir. We use a pharmaceutical grade NIST calibrated pump, which is hands-down the most accurate and consistent dispense out there. We go through a lot of trouble to maintain precise process temp control. Our systems are clean-in-place and don’t require a lot of maintenance.

The @cart.farm is a great damn unit, and if it fills your needs then that is wonderful! @qma is a damn boss and makes a mean setup. We are not trying to compete with them, these are different machines aimed at different market segments, and when customers come to me that are not the right fit due to volume or needs, we often recommend their product.

I appreciate the reply, I am at a volume where id like to upgrade from the cart farmer but I was genuinely wondering if the semi filler would really be that much faster. Definitely think you both have great units ![]()

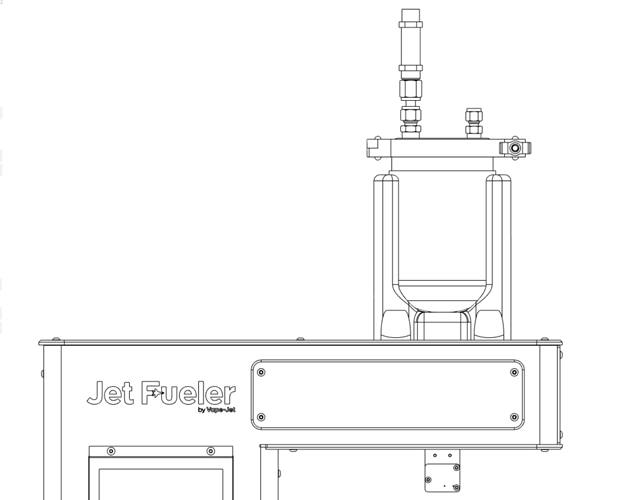

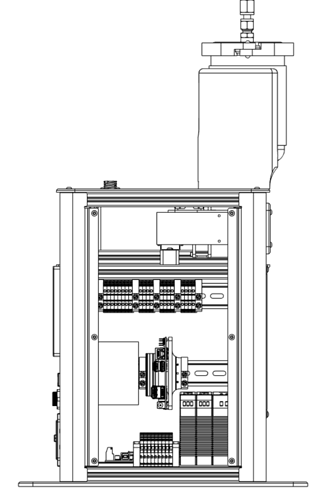

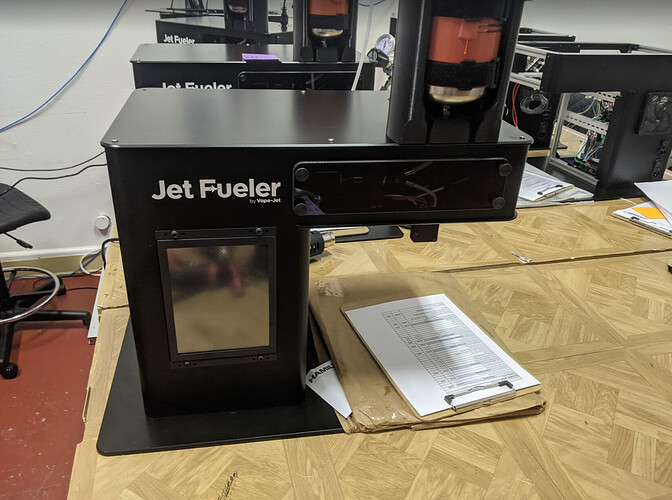

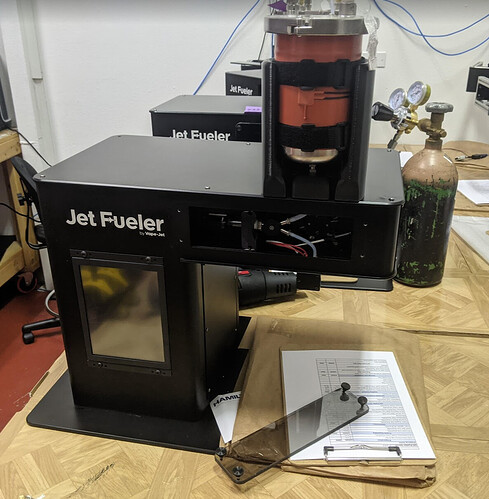

We are finally ready to officially unveil the Jet-Fueler 2.0 Semi-Automatic Cartridge Filler

This unit represents a big jump ahead in overall build quality, as well as the first major upgrade to our fluid path since release. Working with @N.B.OLER we switched to a bowl-reducer style reservoir, eliminating the dip-tube used with the old system, and drastically reduced the feed line length.

This reduced line length reduces the total prime volume needed, as well as the reservoir operating pressure. Another benefit of the bowl reduced reservoir is that the system is designed to be 100% clean-in-place and comes with a self-cleaning cycle. No more 3/16 wrench needed for the compression fittings!

Other than that, the fluid handling system of the Jet-Fueler 2.0 is the same as all of our other platforms. What this means is unparalleled accuracy and repeatability, backed up by NIST traceable unit testing of every pump.

We also upgraded the internal wiring system to help make field repairs quick and easy. Sometimes components fail, and easy servicing with live support is just a call away. We designed 2.0 from the beginning to be both aesthetically pleasing as well as ease of manufacturing & service.

As always, we try to source and manufacture as many components as possible in the US.

- Every unit is hand-assembled in Portland, OR.

- The clear front covers are milled by a local shop in Beaverton, OR.

- The sheet-metal fabrication and screen printing is done in Cornelius, OR

- Reservoirs fabricated by @N.B.OLER of Bend, OR.

- Wiring harnesses hand-assembled in Rainer, OR.

- Aluminum plates milled by a machine shop in Detroit, MI.

- Powder coating by finishing company in Portland, OR.

- Pharmaceutical grade pump made in Reno, NV.

- Silicone heaters fabricated in Cookeville, TN.

- Coil heaters fabricated in Cookeville, TN.

Where we are unable to source US, we make sure to use quality components, such as overrated Meanwell power supplies and fans with self-stabilizing oil pressure bearings. We pay the McMaster tax, because we are low-run and value quality assurance.

And finally what you probably skipped over all of this to see… the pictures.

Taking everything we have learned, along with the support of our customers and partners, we have also drastically improved manufacturing throughput as well as our product unboxing experience.

The first batch machines will be finishing up the end of this week, and are already pre-selling quickly. However we still have units that are free to purchase that can ship by the end of the month.

If you are interested in learning more, drop us a line at sales@vape-jet.com and we will get in touch!

How many units this does an hour?

@Ola see reply above with more details.

I can save you some money on them steel parts. ![]()

![]()

I already told them, they got a lotta shit going on rn

Which steel? Most everything is Aluminum =)

Always open to options as long as they are US based. I don’t have any interest in using overseas machine shops at this time.

That said, I have a metric fuckton of prototyping to do at the moment, and a broken down CNC mill at the shop /w 14+wk lead on the replacement parts.

EDIT: Unless you mean the stainless reservoir / fittings, in which case, it would take a miracle to get me away from N.B. Oler =) Staring at his work is like looking at weld porn =)

it was a joke… no worries… sounds like you have enough on your plate…

I do need a good machinist to work with, or someone in PDX to just let me rent their shop =) I promise I only occasionally crash heads!

Maybe nboler has someone??

I know some good machinists in Oregon.

Subzero scientific if you’re looking for someone oriented in the industry.

Hecker Machine Works se queen rd Milwaukie.

Helped make a lot of rosin press products.

I have a few names for prototyping that sound up your alley but they’re all on the wrong coast for you

TY all for the recommendations!

For the first time ever, we have no lead times on Jet-Fueler machines! Reach out to me here, or contact sales@vape-jet.com to find out more.

We have been using the jet fueler for almost a year now and I would steer clear if possible. Been vary disappointed recently and becomming increasingly frustrated with the device. My main gripe is how long it takes to fill the syringe after it resets (yes, we have decreased viscosity as much as possible). I’m just sitting there after filling each cart for like 10 seconds while the syringe fills back up just dreaming of my seripettor setup which filled 100 in less than 5 min. Then every time you press the pedal there is an error message stating to wait until pressing it again. Then there are the general software errors associated with having a full operating system running the device. It needs to be connected to the internet or it will take 10 min just to boot up. I have tried setting up and loading programs for different cart types, but they don’t work half the time and were not loading volume fill data (dumped a full gram into my half gram cart a few times). If you are looking for a quick, easy cart filler to get started then look elsewhere.