you guys are backed up… I need something now… too bad… I am spending money and time is money… maybe the next time around

The time fixing/troubleshooting a sub par machine will be money too ![]()

then I won’t buy a subpar machine… I have done my research… there are solutions that will work just fine. I appreciate the chime in.

Yeah, but there are some great solutions out there.

Thompson Dukes are proven and time tested. ATG has a super awesome machine shop and versatile platform. @qma knows his shit and holds so many hands. (Can’t wait to see the US farmer!) There is one big player in the space I flat out don’t like, and that’s because I get to hear stories of person after person getting shafted by them.

100% and we understand that. Hope you get what you need, and keep us in mind for future expansion or if you just want to chat.

We are hoping to speed up production soon, but until then we only require a 15% deposit to hold your place for anybody without immediate need.

I totally will. I have watched all your videos and I feel you have a good system. 710 Shark is the one that is awful and the one you’re talking about, but I respect your candor about it.

Have you ever heard about the A-10 Hot Shot 1500… it seems pretty solid. Seen a few reviews about it and it looks good. Thanks so much… I will be buying new machines in the future. So, trust … we will be working together one day.

Thanks for your insight.

Heard of it yes. I’ve never played around with one personally. However I do have a customer who uses our fully-auto system, as well as the A-10 semi-auto system and he is happy with the performance of it.

Thanks for the link, it is a solid machine with only a few hours of time on it, and a nice and big air compressor to go with.

I fully understand and it’s no rush, only great things to come from here man! I was more teasing then anything ![]()

Super stoked on the pid heater, that thing will make life so easy!!

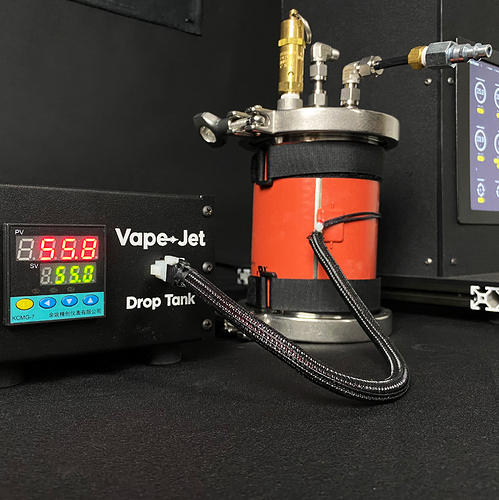

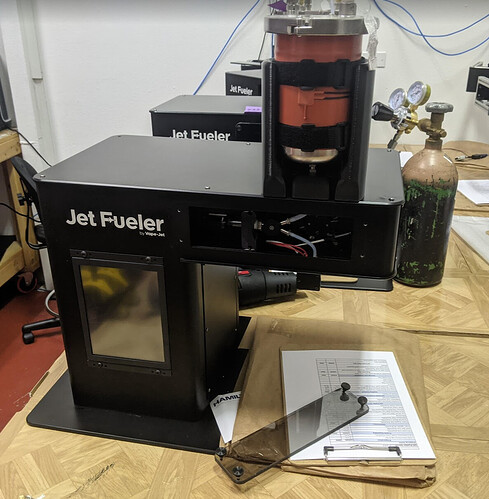

Speaking of the external heater =) It is now available.

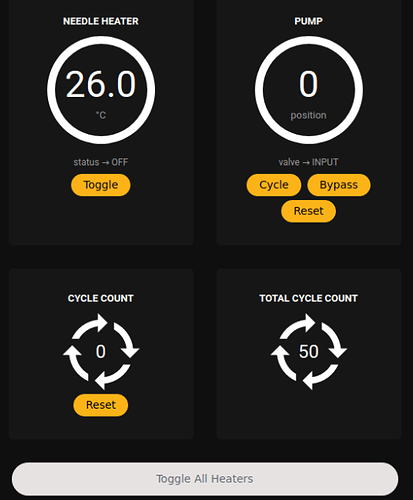

Also did some basic software updates:

Added Cycle Counters (Track how fast your employees fill.)

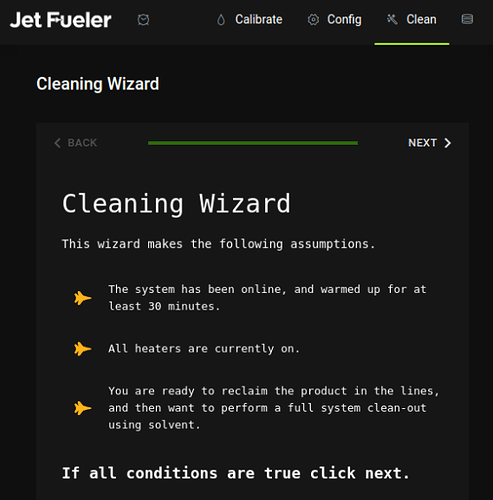

Also added a cleaning wizard, which walks you through the clean-out process.

Wait so you press the pedal and grab each individual cart hand by hand to fill like in the end of the video?

Yes. There are many advantages to this. Capping packaging can get started right away. Also with a good operator is as fast if not faster than having a robot do it.

I would like to learn the advantages of grabbing each individual cart to fill. I thought people just held the trays up to fill this style machine

You can do it either way. I’ll send you a video on what’s app later today.

I have the 1000 cart farmer and was looking at your fully automatic and saw this but I honestly would think that this would be slower than my cart farmer.

@calmcbd it is entirely up to the operator, your oil, how hot you want to get it, how big of a needle you are using, how fast you can fill without overflowing the sidewalls, etc. etc.

This is a foot-pedal operated unit, not a hand-operated unit. The pumping force comes from a motor, not the users hand. We use N2 displacement in the reservoir. We use a pharmaceutical grade NIST calibrated pump, which is hands-down the most accurate and consistent dispense out there. We go through a lot of trouble to maintain precise process temp control. Our systems are clean-in-place and don’t require a lot of maintenance.

The @cart.farm is a great damn unit, and if it fills your needs then that is wonderful! @qma is a damn boss and makes a mean setup. We are not trying to compete with them, these are different machines aimed at different market segments, and when customers come to me that are not the right fit due to volume or needs, we often recommend their product.

I appreciate the reply, I am at a volume where id like to upgrade from the cart farmer but I was genuinely wondering if the semi filler would really be that much faster. Definitely think you both have great units ![]()

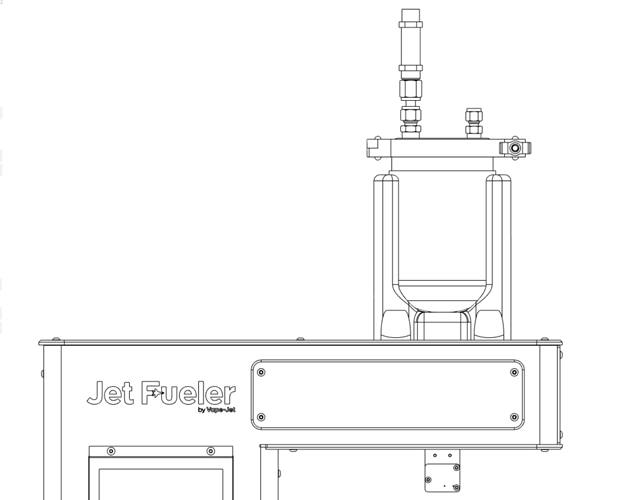

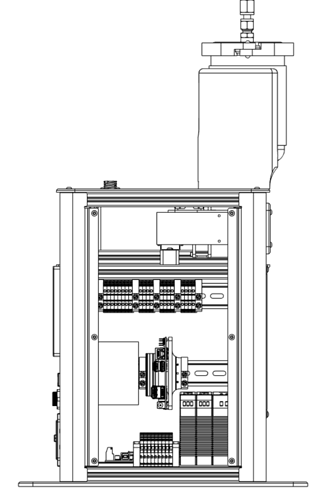

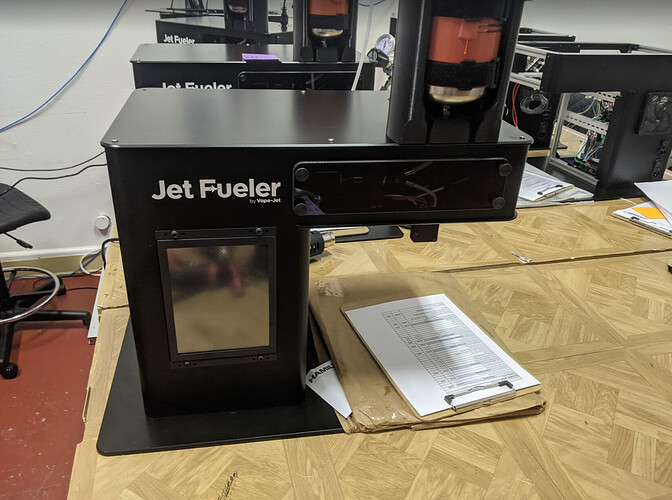

We are finally ready to officially unveil the Jet-Fueler 2.0 Semi-Automatic Cartridge Filler

This unit represents a big jump ahead in overall build quality, as well as the first major upgrade to our fluid path since release. Working with @N.B.OLER we switched to a bowl-reducer style reservoir, eliminating the dip-tube used with the old system, and drastically reduced the feed line length.

This reduced line length reduces the total prime volume needed, as well as the reservoir operating pressure. Another benefit of the bowl reduced reservoir is that the system is designed to be 100% clean-in-place and comes with a self-cleaning cycle. No more 3/16 wrench needed for the compression fittings!

Other than that, the fluid handling system of the Jet-Fueler 2.0 is the same as all of our other platforms. What this means is unparalleled accuracy and repeatability, backed up by NIST traceable unit testing of every pump.

We also upgraded the internal wiring system to help make field repairs quick and easy. Sometimes components fail, and easy servicing with live support is just a call away. We designed 2.0 from the beginning to be both aesthetically pleasing as well as ease of manufacturing & service.

As always, we try to source and manufacture as many components as possible in the US.

- Every unit is hand-assembled in Portland, OR.

- The clear front covers are milled by a local shop in Beaverton, OR.

- The sheet-metal fabrication and screen printing is done in Cornelius, OR

- Reservoirs fabricated by @N.B.OLER of Bend, OR.

- Wiring harnesses hand-assembled in Rainer, OR.

- Aluminum plates milled by a machine shop in Detroit, MI.

- Powder coating by finishing company in Portland, OR.

- Pharmaceutical grade pump made in Reno, NV.

- Silicone heaters fabricated in Cookeville, TN.

- Coil heaters fabricated in Cookeville, TN.

Where we are unable to source US, we make sure to use quality components, such as overrated Meanwell power supplies and fans with self-stabilizing oil pressure bearings. We pay the McMaster tax, because we are low-run and value quality assurance.

And finally what you probably skipped over all of this to see… the pictures.

Taking everything we have learned, along with the support of our customers and partners, we have also drastically improved manufacturing throughput as well as our product unboxing experience.

The first batch machines will be finishing up the end of this week, and are already pre-selling quickly. However we still have units that are free to purchase that can ship by the end of the month.

If you are interested in learning more, drop us a line at sales@vape-jet.com and we will get in touch!

How many units this does an hour?