I figured that not enough head pressure was the issue so I slightly opened my vapor port and kicked on the recovery pump to basically push the gas through it just stalled as soon as it got to the crc column and stayed for hours. I for sure need to switch those out clamps out as to why i don’t use nitro assist and try to keep recovery temps no more than 85f

You need to just get rid of the 20, and pack celite right on the 8um.

First and foremost you need to properly clean the sintered filter or none of what you change will matter

Adding n2 to the mix will change your life

Or end his life with single pin clamps.

For sure not equipped for n2 assist even though i know its a game changer . Those single pin clamps are rated to 500 psi at 70f I’m not even reaching 100 psi during recovery. Still going to change those out thanks for bringing it to light sometimes we just tend to overlook certain things when things are just working as is. Time to sit and evaluate everything and make some changes

Do your filter papers have proper supports? Mine never blow out and I run a ton of nitro to go fast as possible

Stage ur filters above the disk . Several to keep fines out of it. Seat ur papers properly on the supports they should never blow out really

double your filter papers, and if your trying to use without backing support for the papers it’ll tear everytime

I can’t thank you all enough for your openness and willingness to share. So cool to learn something new and have genuine help.

THANK YOU!!!

I was going to post a video but forgot how. Lol

All my concerns were answered in the tips and tricks thread along with everyone’s help here mannn i love this forum so dam awesome!!! next on this list poly filter sheets!!!

@shadownaught Are there any updates with the T41?

I’m sorry to harp on the subject so much but I’ve been dealing with flow issues and inconsistencies with T41 since last August.

I believe I was one of the first people to receive the sub par product way back then. I had a shipment due from you that was late by a week and when I called to ask about it they said they were waiting on a new shipment to arrive and would send my order ASAP.

When I finally got the new clay I noticed right away it was a darker color than usual.

When I tried it I noticed a significant decrease in flow rate. Back then I was using a 4" wide CRC and my time to clear a 6x24 doubled from 8 minutes to around 15 minutes. There was also an increase in yield loss to the clay. Before this point I had gone through about 50 kg of “old” T41 so I was highly familiar with how it performed. I always keep notes and write down how long it takes to flood and clear my columns.

I called customer service right away and let them know. They said they would look into it.

I then spent a few days continuing to experiment and waste runs/material trying to figure out if it was the clay or somehow my SOP that was causing issues. Customer service contacted me and initially thought I was dealing with water logged clay so I baked some and did more trials with no improvement whatsoever, just more lost production and time.

At this time (last August) I sensed trouble on the horizon and was very worried because of the approaching harvest season. Thankfully, I was able to get the very last 30kg of “old” T41 from @Killa12345.

As I worked through that 30kg of good stuff I eventually received a new 25kg replacement batch from Carbon Chem with no explanation whatsoever about what was actually happening.

I finished the 30kg from killa and eventually (about 2 months ago) got to the new box that was sent as replacement. It was still the same darker color as the first box and only flowed marginally better but still noticeably worse than the “old” stuff.

This occurrence now makes sense because you explained earlier in this thread that only 2 out of 10 tons you received were barely at an acceptable level. I’m guessing the first box I got was from the 8 tons that were rejected.

Can you comment on exactly what the issue is/was here? I could tell visually right away that the clay was darker than usual when I got the new stuff in August. This makes me think there is too much carbon in the mix and/or the clay and carbon were not blended properly. The way the new stuff seems to rob more yield and taste seems to reinforce this hypothesis that there’s too much carbon.

Now I have gone through that entire 25Kg of barely acceptable new stuff that was sent to me as replacement. Last week I got the last 5Kg that killa had in stock and it flows like the initial, very bad batch that I initially received in August.

This inconsistency is frustrating to say the least, as I’m sure you’re aware.

Can we expect any improvement back towards to the “old” characteristics in this new batch of T41 or will it remain the same?

For anyone wondering here is a pic of the clays with T5 on the bottom for reference, then the “bad” T41 in the middle and the old “good” T41 from before August on the top. The difference is more noticeable in person than in the pic.

I can tell from the fact that T41 seems to “fly off the shelves” when it’s in stock that plenty of people are using it for CRC but I don’t see anyone discussing this issue on the forum.

I came across this and thought I was an interesting reading. Not relevant to extractions. The beneficial uses of bentonite clay for our health. Lot of misinformation out there these days. Always have to do our own research. Thought this would be worth sharing.

did anyone get a plug on the opaline silica?

For the guys coming on the thread 7500 posts in and not reading the first 3k. In the beginning we didn’t have the sintered filters and just ran paper filters. @Killa12345 saw first hand what happens when a paper filter blows and it ruins 2kg of extract. After this I personally started running a stack with 4 filter plates each with a paper reducing in um. The sintered filter was/is meant to be a lifesaver if your filter paper gives. If you just run 1 or two papers, say an 11 then a 5um with the 5 on top of your sintered disc you won’t have to worry about cleaning the disc.

Each green line is a filter paper.

You can ask @Killa12345 how I begged for sintered filters.

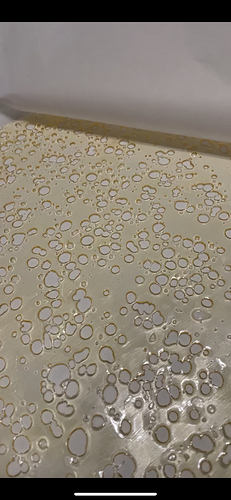

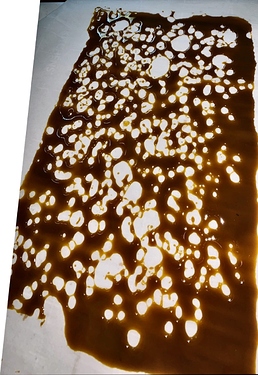

yo yo waddup fellas, been keeping up with thos post for sometime now, appreciate everybody dropping some knowledge, wanted to share my work!

I am pretty consistent in getting water clear/super bright results, my crc consists of

Silica

T5

T-41

Im still a newbie (4 months in) and just started but i am happy with my results for the most part!

i use about 1100g media for every 12lbs of material and run about a 5/1 solvent ratio, i pack all media through a vac and do not prerun with solvent or bake my media. i would say my only issue is clogging every now and than even with the use of n2 i get to about 100psi and my flow will just stop, resulting in losses. any idea what i can do to prevent this?

appreciate the feedback!

Makes sense the sintered being used as a fail safe for paper filter blowouts. I’m getting the poly felt filter sheets and see if that helps with depth filtering. I have 3 filter plates going to try the 10, 5 , then 5 sintered I saw they have 1u but im thinking thats too much. By the way I have the same L brackets holding up my columns so dope!!! Those sight glasses makes me think of creating a bypass for the crc in case it’s already a nice color no need to pass through the media but I guess you could predict quality/color based on how the starting material was kept. Thanks for the info!!!

if you look a few post up you will see I post a clogging issue , seems my filters are the issue mainly the 5u sintered disc the culprit of being clogged. Going to switch up on the filters to see if that helps.

@FicklePickle had a good suggestion:

I pack celite onto an 11um filter paper in a stack, 6um paper in a stack then a 5um sintered filter stack and another stack with 2.5um filter paper. Never seen a single blow by, clog, or even reduced flow

That’s the idea and why I have the filter stack isolated.

I might of missed a mention of this in previous comments but has anyone tried this with loose adsorbent in a larger vessel like a jacketed honey pot prior to final collection? It seems like two of the biggest issues (clogs and filter blowouts) could be mitigated this way… Agitation could be aided by bleeding in gas from underneath or using a overhead stirrer with a motion translation gasket that is rated for high psi…

Just a thought

It’s mainly the hardware. Cheapo stacks with compression rings. Running fairly warm too so I don’t want it to go through too quick!

I found I was freezing my crc column by running my recovery pumps hard and not enough nitrogen I found the solution was to make sure the n2 is pushing the butane thru the crc before you turn your recovery pump on and always make sure you have enough n2 pressure 35-50 pounds seems like the magic number for me