Solvent 1: 10

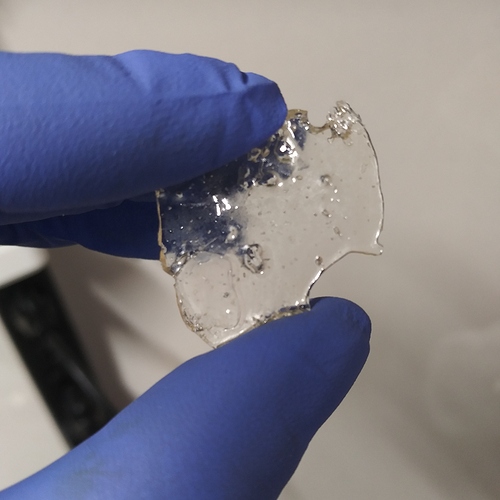

Almost there! Water clear when thin. But when over 3-4mm thick has a slight yellow hue to it.

Used a 10:1 pentane solute with a buchner and baked B80 & Silica 60.

@CalyxKid I know you said you got it fixed but replace these cotton balls with the poly filter sheets and you should have no issues! Cheers bro!

I am trying to find a good deal on bulk t5 and silica 60 can you help me out? And thank you for all of the info I have learned a lot just reading your comments!!

Have you tried b80?

It’s only $1 a lb

No I have not yet I read a few comments people were having a hard time getting clear with out t5 but I am open to any thing that is cheaper and still works I’ll have to try it

Wow!!!

And no t5 that’s crazy!!!

How often would you recommend cleaning the filters

I clean at end of day. Run about 10# of material through. 2# at a time. Replace b80 between runs.

I have great results with only B80. And have also had good results running only supreme 55

Wow, that took a while but was well worth it. Thank you to all who took the time to share the info. Now it’s time to get to work!

So I finally got to toying around with media filtration, and after getting a few runs in dialing in the process, and finally feel as though I have 2 cents I can add.

I started with

100g Silica 200-400 mesh

300g T-5

28g celite 545

First run I had troubles, filter media permeated just beyond the last filter in my filter stack, which is as follows.

Column

26um filter

Filter cake

2x 26um filter

2x 11um filter

2x 6 um filter

Sintered

And yielded something looking like this:

I have since added as many filters as I can fit in the filter plate between it and the ring, and adjusted filter media content in hope of reducing movement of media powders.

Silica 150g

T-5 450g

Celite 56g

And filter stack as follows.

Column

4x 26um filter

4x 11um filter

3x 6um filter

2x 6um filter (on top of sintered)

With this I have seen complete reduction of disruption of media, and don’t find content past the first set of filters. And over all the polishing really does wonders on this material, I haven’t quite gotten that glassy color, but I believe I am on the right trail.

My biggest pickle that I’m trying to break is the silica seems to want to move upward with the vapor path when I’m vaccing down the column, even with filters on top of media powders I can’t seem to keep it from flowing with the air current, and has gotten me considering removing the silica altogether since its nature kind of bugs me. Any sly suggestions would be appreciated on this.

Thank you @Killa12345 for the hardware and quick reference knowledge, you really helped me wrap my head around things and gave me a baseline to work from, and a thank you to everyone on this thread as well who put in their two cents, I hope to continue to grow and learn here.

Vac from the bottom . How much are you running at a time @TheGooMan

@710enigmatic 1000g per run through 4x24 column. Usually run 2-3 runs through until I see slow color shift from degradation of media’s absorptive capacity.

Use a celite or d.e pancake on top the silica to hold it down maybe?

@StoneD you just nailed what I have been considering, my vac seems to struggle pulling air through the media, and through the material, so I have to pull from up top, i just need a denser material to hold it in place i suppose, will continue to finagle with it.

I’m confused as to why you’re pulling vac from above, that will destroy your celite cake and create blow by. I’m beyond meticulous about this. As long as you never destroy the celite. You can use the cake all day long.

And you really seem to be over doing the filters.

Am I reading that correctly that you’re using 4 of each filter paper?