Soaking in iso wont remove fine particles. It will only dissolve any remaining oil

Im going to bake the media and see if that helps with the flow as I have gone through 2kg+ of each powder with the same procedure and no issues ,no stall. This is the first time I’ve actually had any issue at all. What do you recommend? I usually have acetone around but only iso today plus I clean every run columns,base,crc column so it’s hard to point the finger towards particles in the filters idk could be though.

I use an ultrasonic cleaner. Alcohol first followed by distilled water

I also keep collection on dry ice to avoid vapor lock

Baking won’t have any effect on what your experiencing. You either have a clog or a vapor lock. Your collection base wasn’t hot was it?

Vapor lock as in vapor pressure not allowing the gas to come through to the collection base ? My collection base stayed in negative pressure so I don’t see how that is even possible. And yes the collection base was kept cold as why it stayed in negative pressure.

You can have a hot collection base under vacuum…

Filter blowout and your trying to filter the powders out?

Im very aware of hot collection in vac, I know its something with the crc column because when I remove the feed line from the material column to crc and put it to the collection base it all started flowing like normal so that’s why I don’t see how its vapor lock from the collection base.

Your sintered disc is clogged with media

No filter blowout in fact I would rather that happen then what im experiencing now. Its just not coming through the crc like usual

Clog.

20um ss screen holding back celite seems like a major oversite on your part.

I pack celite onto an 11um filter paper in a stack, 6um paper in a stack then a 5um sintered filter stack and another stack with 2.5um filter paper. Never seen a single blow by, clog, or even reduced flow

Are you packing the celite?

I pack mine with a wooden puck cut to fit inside the 3” stack. Then I press a 1” thick puck of celite with all my body weight. Then the rest of the media is tossed in loose above that

I guess it’s a matter of doing a process of elimination. Media is being baked if that doesn’t work then I will change the filters. Its just crazy that i’ve done numerous runs with same micron screens and same procedures with no issues then I run into to this problem I don’t see what changed… anyhow I appreciate the responses will take all advice in to consideration

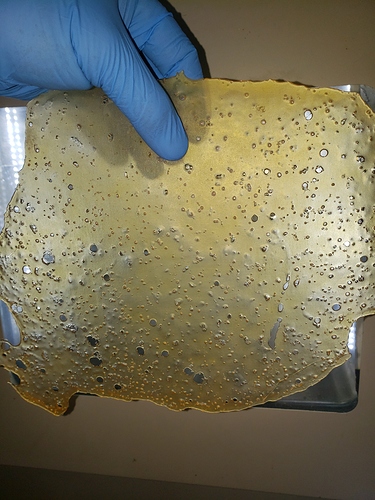

here is some pics of successful runs with the same micron screens and media

Yea I have been wanting to change to a smaller size um to hold the celite also using a paper filter. Being that I used a bigger size um one could assume that it would flow faster. yes im packing it for sure same as you using all body weight. I even considered I was packing to tight which may have caused it to clog but people are using mechanical presses with success so i’m not sure if that is even the issue.

get a bigger crc

Have you tried running less No2 pressure ?

I had filters blow constantly. Was able to stop it by switching the 1u with 5u. ( some people will prob disagree as some particulate May find way through 5u)

I would leave No2 pressure very low. Gradually increasing and checking honeypot for action.

Every time I pressurized and tried to open valve on reducer to honeypot the paper would blow. My taxtractor Depot ball valves are shitty but I’ve started to throttle them. I usually start reclaim slightly open then gradually increase as column drains.

Just realized you’re using a coil in between your solvent tank and column. You probably didn’t have enough head pressure to keep the flow going. You state you could only get 8# of solvent in… Your problem ( if not a clog ) is you don’t have sufficient pressure in your tank to flow properly/dry ice coil stalled you. Try it without cooling your injection. Majority of people will need n2 to push through a media bed, which I absolutely don’t recommend considering you’re using single pin hinge clamps on your collection base. Change those out ASAP.

God this is silly. You clogged it.

One would not assume that a higher um is going to help you with flow. The higher the um the easier all the powder can slip by. Thus clogging your sintered filter.

Sorry if it sounds silly or if I came off condescending just trying to narrow down the issue, I based it off the earlier readings and recommendation for micron sizes 20,8 , then 1 even Bvv crc filter recommends 20,8,2.5. Im doing a 20 , 20, 5 sintered ,1.5 and then 50 mesh gasket. I will adjust the micron sizes and see it that works just thought it was a matter of excess moisture in the filter medias more then the micron filter sizes. Thanks for the input ill try the 11,6,5 like you suggested