how do you know when the solvent is gone and the terpenes start evaporating?

You don’t. The “terpenes” are evaporating along with your solvent no mater how much you want that to be untrue. The extent of that evaporation certainly depends on your solvent of choice, and the conditions under which you’re evaporating.

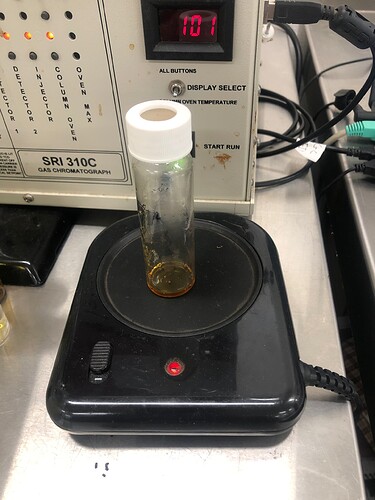

OK, so how do you optimize your purge to hit state mandated residual solvent levels while retaining your desired volatiles?

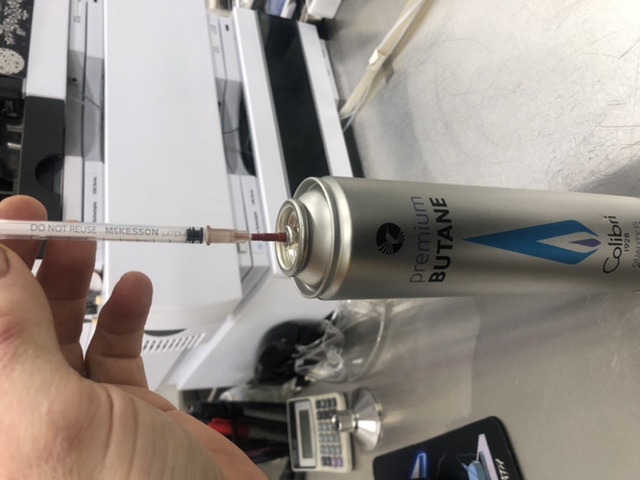

By testing !!! preferably in-house so you don’t have to deal with the cost & lead time, or those pesky “fails” on your record.

In the past I’ve concluded that headspace for terpenes was qualitative at best without a dedicated headspace unit with heated vials and transfer lines. Which the SRI8610C I was using at the time didn’t have.

Now I’ve got an SRI 310MM which has both an MXT-500 and a Hayes-sep D/R packed column. Along with a couple of surplus headspace auto-injectors (salvage auction, sitting in the corner waiting for a new lease on life. Will link thread here when I get to that part).

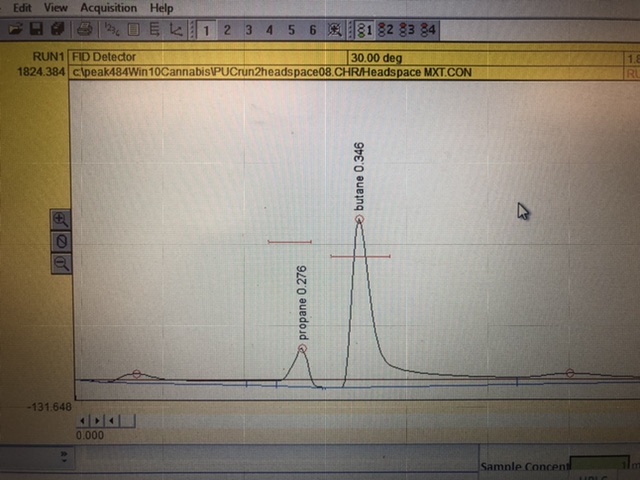

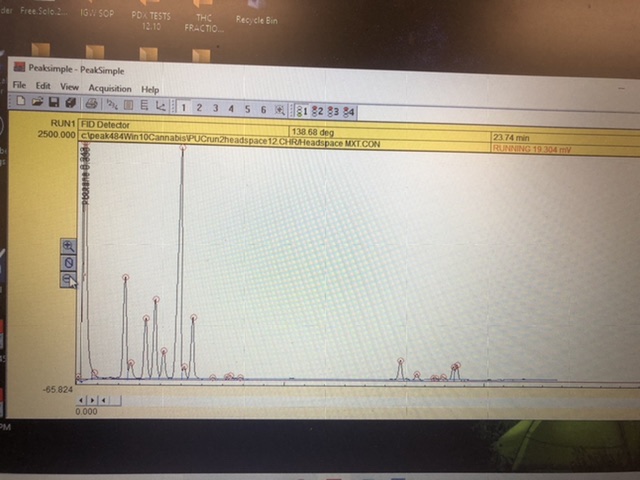

Before taking on the auto-injectors, I’d like to get a handle on separation. And so far I’m not doing too well. Seems like my predominant terpene is running almost right on top of butane on either column with the temp profiles I used so far.

The MXT-500 seems to resolve the (other) volatiles (let’s call them terpenes) considerably better than the Hayes-sep. the Hayes-sep can resolve propane and butane, but doesn’t seem suited to generating a terpene profile.

Has anyone else gotten reliable residual solvent (specifically butane) testing running in house?

How?

I’ll get chromatograms up when I get the chance…