sooo…

I didn’t get to play with my current set of centrifuges on Friday, because the chiller had quit…but it had quit in a manner we’ve seen before, and one that points to a problem with our 3-phase power if I’m reading it correctly.

Chiller states it will draw max 26A, yet repeatedly (three times in the last few months) according the the tech I talked to, we’ve had them burn out one leg AT the (30A 250V twistlock) wall socket/plug interface.

to me this says one leg is low voltage…but I’m a biologist and the only formal electrickery I’ve had was back in high school.

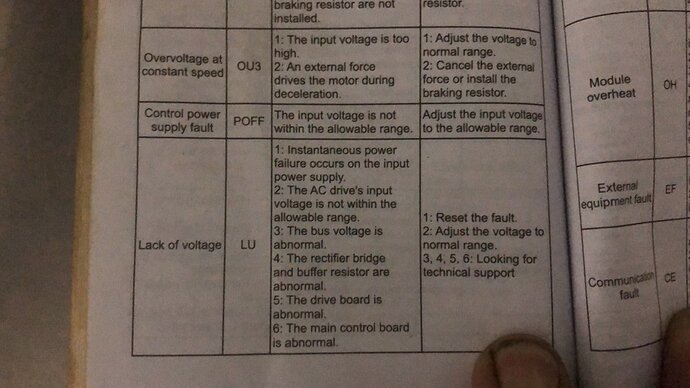

I tried playing with one of the fuges anyway, because I don’t need cold to figure out spray patterns or appropriate spin speeds (ok, I do, but I can get close)…and the thing kept throwing LU.

quick check of the fine manual reveals LU == Low Voltage! (why U not V?!?)

yes, there are other excuses for that particular error, but combined with the chiller on the same sub-panel pulling too many amps on one leg, I’m not sure there is a whole lot of point chasing those down.

not sure what it is about my whirled, but it seems that I’m plagued by “I can nay get the power” wherever I go…

Anyone able to suggest other options? How hard is this gonna be to track down?

Rumor has it the pro’s will be in tomorrow to at least address the wall socket the chiller took out…will I have any trouble convincing them it’s a low voltage problem? (Nah dude, it’s the POS chiller!)

seems like sag under load to me…is that gonna make it harder to solve?