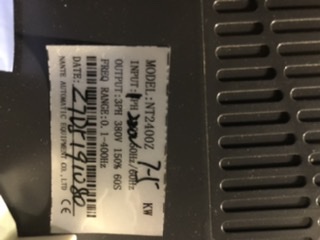

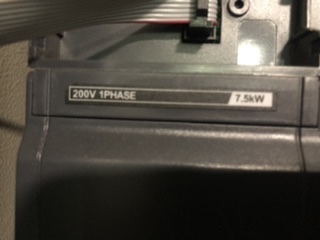

Voltage imbalance is not a concern on single phase circuits. Your voltage is a little low but the drop is not unacceptable. This type of installation is uncommon. Typically a drive fed with 2 hots would come from a split phase system and the voltage would be in the 240v range. For a temporary set up you would be fine to lower the low voltage setting on the drive. If it will be more long term I would look into getting the 3rd phase into the drive and reprogramming it.

Yeah, that’s where I went too.

I’ve got three wires heading into the VFD. Red, black, green. 116V to ground for red & black. 202 betwixt them.

As @SidViscous mentions there is probably somewhere I can twiddle a setting to relax the voltage requirements, and as you pointed out the 3-phase chillers eating a pin on the twistlock plugs might well be a flaw there not with our power in general.

I’ll make sure to catch the electricians tomorrow…

Doh!

Yep, I was actually surprised when I found the supply voltage was single phase this morning…

Feeding it three phase usually increases the amount of power I can get out too right?

I certainly remember having to derate by 50% when feeding single phase on at least one occasion.

Probably might be overstating it. I know Lenze drives are fairly particular, Hitachi and yaskawa less so, siemens are pretty flexible

Pdf warning fine manual is big!

There will BE no three phase input!

I’ll try and arrange actual 208, and see if I can find the “it’s ok sweetness, 190V is plenty” check box.

Might just have to stay below 40Hz until I can throw more parts at the problem.

…but the 1-400hz on the sticker has not gone unnoticed ![]()

I’m not sure why running low speed would help. If it’s throwing an error for low voltage that has to do more with sag during starting draw and it will likely still error out. I’ll peruse that fine manual for the appropriate parameter.

Is the transformer that you’re powering it with your own equipment? You could check to see if you can bump the taps depending on the type to get a few more volts.

I’ve got 7 of these. The only one throwing LU so far is the one I turned up to 11 (ran it up to 70hz to hear her sing). I’ve since turned the max allowable to 65, and at 40Hz it doesn’t error out. At 50 it does.

Mind you, that could be the 60 sec at 150%…it gets to 40Hz and stops accelerating before it times out…

Bearings don’t sound great in this unit, but are currently better than the one next to it (documented elsewhere).

Goal is to get them as efficient as possible with essentially parts on hand, to convince the boss they’ve been doing it wrong, then leverage that for more parts to get it working right

If that means longer slower spins, it’s what it means…for now.

Really appreciate the help y’all!!

I’ve seen this somewhere before…

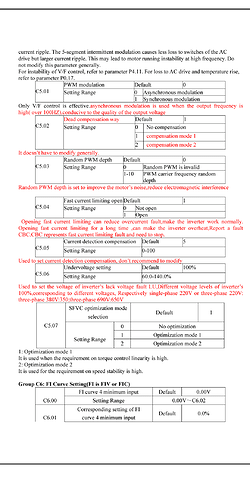

Check P2.02 - I’m scrolling through now but it could plausibly run off of the motor voltage parameter.

As far as tripping on one and not the other, if you’re right on the edge it’s not too surprising. Hell, an extra 20 feet of wire could do that. I could also just be totally wrong with this diagnosis lol

It was NOT throwing errors before the chiller in the next room (chilling 4 fuges) got pissy with its power plug…I got it up to 75(?)hz unloaded and had it at 65hz loaded when the bags got too tall and hit the lid…with no complaints.

Next day, chiller was fried and fuge wasn’t willing to hit 60 or even 50.

I’ll bring my own meter and check out the other boxes tomorrow. Set two more up to hit the high notes & see if they complain or not.

Then beg the electricians to find the transformer and up the voltage. It’s not like we’ve got anything that actually expects 208V…

You should definitely try to get the system voltage up but keep an eye on the hot to neutral volts at the first beaker down from the transformer. I wouldn’t push it much over 125 v especially if you are loaded up pretty good.

You could always make up a 10% boost transformer cord assembly and put before the drive.

You would just need to size it to the load.

Yes your luck with chiller compressors may even improve if you get lucky with adjusting the taps. Regardless, changing that parameter will hopefully make that pesky LU go away

This is also a good idea although 7 of them is gonna get expensive

Set C5.06 to 0.85 and give it a swing!!

Sounds like a plan…

That was the CURRENT limit they recommend not changing… C5.05

Ahhh. Yes. Maybe leave that one alone…

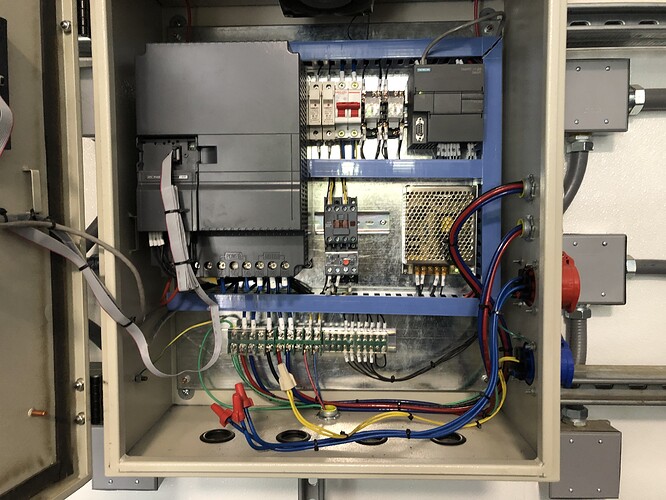

Just curious. Does this control panel come with the line and load reactors installed as indicated on page 10 of the manual?

Doesn’t look like it…at least in this picture from last week.

Had to go look up “AC Reactor”.

I’ll take another look tomorrow

Edit: nope, don’t see either…in either version of controller!

Looks like we’ve got 2500A service coming in at 203V. Not our transformer. Hoping we can get the power company to solve that…

Fuge that was quitting at 199V was doing exactly what it was told (C5.06 set to 90%).

Now that I’ve told it

It does what it’s told when asked to go 60Hz

You’re probably SOL unfortunately. Usually their transformers are wet type and built to spec so there’s no taps adjustment