Decarb and vape tips. (Cool down method) Scroll down to the video part if you know the basics.

![]() You dont need a bunch of fancy expensive equipment to make high quality vapes! Just good full melt sho or some good live or cured resin! Mason jar,(or small glass jar w lid) heat source and some good vape hardware.

You dont need a bunch of fancy expensive equipment to make high quality vapes! Just good full melt sho or some good live or cured resin! Mason jar,(or small glass jar w lid) heat source and some good vape hardware.

(I’ll post hardware info soon)

Ea batch is different! not all rosin/resin decarbs and finishes at the same time. (Multiple variables)

Viscosity plays a big factor in efficiency, weather it vaporizes well or not…We can alter viscosity through decarboxylation and/or adding terps. CDT/HTE (full spec terps best imo, the fraction)

thca % presence plays a big factor as well.

Many don’t decarb long enough, the oil re-nucleates/ re solidifies and won’t vaporize efficiently.

Decarb too long… Large volume loss, sedative buzz, degradation etc…

Too high temp… burn terps and other noids. (If any present) Creates too much pressure from CO2 gassin off

Too low… won’t decarb.

Terps act as a catalyst

thcA on its own takes a long time or high temps… you want a catalyst, preferably hte, terp fraction…but 100% CDT works also…contrary to popular belief they can withstand 200f+ when paired with thca and/or other noids.

Volume loss does occur (8%-20% volume loss in my exp. And science says about 12% is avg, many variables though)

Keep it at a min. by checking ea batch w the cool down method…

I start checking every 1-2 hrs after 4-6 hrs …you’ll become familiar after some experience.

Cool down to room temp then stir it up! If it bubbles/foams needs to go longer. Keep repeating the process until no bubbles form after a good mixing at room temp. (See vids)

Viscosity should be like a thick warm honey. (There’s a scale but I’m not familiar)

What it looks like when needs more time ![]()

What it looks like when it’s done ![]()

Those are all full melt hash rosin, same applies to live and cured resin as well.

Viscosity - not too thin / low…burns fast. Not too thick/high where it won’t vaporize either. Sweet spot like warm honey at room temp.

Hardware-

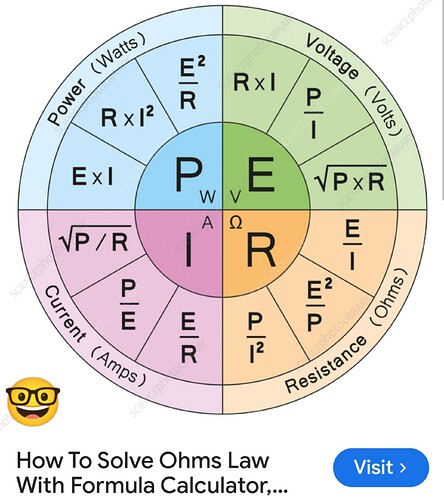

Postless wickless is best imo. But good specifications most important. (Learn ohms law) High coil temps ruins tasty oil. (I’ll make another post about vape hardware)

In my best cholo accent

“watts happening homes”… learn watts. Ppl been saying “I like mine at 3 volts, I like my vape at 2.4 volts” - volts alone doesn’t tell us enough info. See an ohms calculator. You need both volts and ohms to know watts.

Decarbed rosin & resin is more potent b/c it’s more bioavailable.

I do

Hash rosin @- 190f-210f , 4-6 hrs up to 48 hrs (many variables, thca and terp % the biggest, longest ive gone was 30 some hrs) after 4-6 hours I let cool to room temp then stir it up to see if it’s done or how much longer it needs.

I repeat this process every 1-2 hours after bubbles start getting smaller… After your familiar you can tell how the bubbles form about how much longer you need to go.

(Usually finish 6hrs-20hrs rare to go over 20…maybe ppl adding thca to the rosin? ![]() You can learn a lot by decarbing, ppl def been adding CDT to rosin, many aren’t aware)

You can learn a lot by decarbing, ppl def been adding CDT to rosin, many aren’t aware)

*Edit after @SubstituteCreature comment. I’ve gone 160f-170f @ 24hrs -100+ hrs didn’t notice much of a difference. But hes def got more experience than I do.

200f-225f for cured/live resin. 6hrs -48hrs same method as full melt.

Let it cool down and stir it up before you load. If it bubbles it needs to go longer! Be patient keep going until no bubbles form.

I use an air fryer, small glass jars, mason jars, and postless vapes. If you have good quality rosin/resin you can make good quality vapes. It’s important to get all that CO2 out! If you don’t have a vacuum system be sure no bubbles form at all when you stir it up. Stir well.

This is more for the newbs…I’ll make another post w/o all the newbish details