This thread is going to be a quick “how to” in regards to pop-up branding and quick labels and sticker for r&d/marketing.

I recommend reading This thread first to give you an idea of what you may need for compliance it’s a pretty good rundown from what I’ve seen doing consumer packaged goods myself in several south eastern states.

Materials needed:

- Good quality photo printer

- vinyl plotter

- high quality sticker paper

- a decent PC setup (the plotter software is a resource slut)

Printer recommendations:

I recommend two printers for this kind of work, the Epson xp 15000 or the Cannon pixma pro 100 they are both medium format printers so they both print on up to 13" paper and they both have 6 ink cartridges instead of the usual 2 or 3. More color is more better. I personally recommend the epson unless you need to save a few pennies, the pixma is all over the second hand market for about $100 b.c. they gave them away with macbooks a few years ago and people don’t know the value of em lol

Plotter recommendations:

There are two main hobby scale vinyl plotters that are popular The cricut or The sillouette I prefer the silhouette b.c. the blade is automatic so you don’t have to manually change the pressure on your blade every material change. The sillouette also has free software that you can save unlimited designs whereas the cricut is like 5 a month or something which would be a pain in the ass. The sillouette also offers bluetooth even though I always hardwire. Also the cricut required internet and the sillouette doesn’t another win in my book for the sillouette.

Sticker paper recommendations:

Paper quality makes a hell of a difference. You can get The elcheapo amazon special which is about 20$ for a 100 pack or you can opt for the better quality Name brand stuff that comes out to almost a buck a sheet. Depending on the application we go back and forth between the cheap stuff and the expensive stuff.

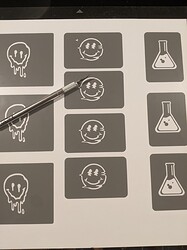

Process flow:

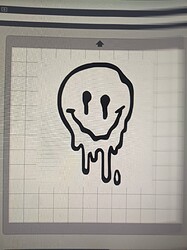

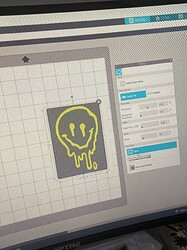

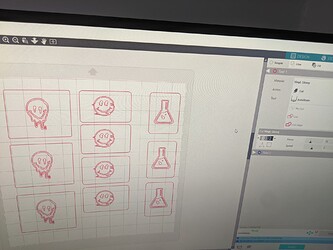

First start up your plotter software. You can design whatever you want in here by uploading any ready done artwork but the design software is intuitive enough for anyone who can use powerpoint to get some light work done.

Once your label design is done (consider the points made in my first link about compliance). Your going to want to Apply registration marks so it can be cut on your plotter. Now that your design is done and you can see your registration marks we can move on to printing and cutting.

Click print and make sure the paper type is correct. Change the print setting to the highest quality and send it. Once your printed you need to stick that paper carefully onto your plotters cutting matt and load it up.

Double check the plotters software to adjust the paper type (sticker paper, printable vinyl, etc) on the sillouette your blade will automatically adjust itself based on your selection here. You will probably want to adjust these setting as you get more familiar with the process but the defaults get you close. (I change my cut pressure down by one almost everytime so it doesn’t cut all the way through my sticker paper)

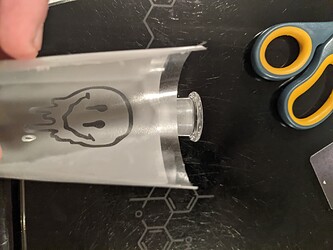

That’s it! It’s pretty easy to crank out a few hundred stickers this way and there’s a variety of paper types available for your packaging needs. If you wanted to really get wild there are tons of free files out there for cutting heavier paper products for things like cart boxes etc. You can also get these plotters in a 14" flavor for about 500$ that would match up wonderfully with your new medium format printer for maximum small scale power ![]()

If anyone wants to drop thier r&d scale packaging tips and tricks here I’ve noticed a lot users that could use a little independence in packaging these days.