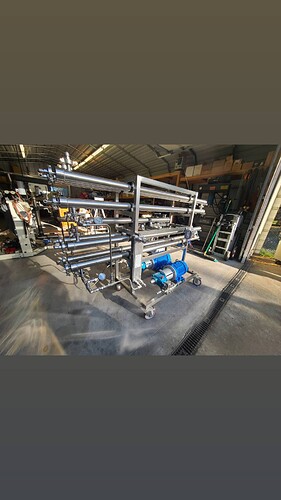

Figured I’d make a post on here to introduce my equipment company and our membrane skids

This is our 60 GPH 2in1 membrane skid for winterization and solvent recovery.

This skid can be used for winterization, terpene seperation, color removal or solvent seperation based on what membranes you put in them.

This setup is currently being peer reviewed by PSI for C1D1 certifications.

These skids will work with ethanol, methanol, ethanol denatured with heptane, hexane, pentane, butane, propane, isobutane, and toluene

Our skids include a heat exchanger for temperature control and a c1d1 remote controller attached on the skid for the control area

PLC and full automation add ons are an option (this is our most basic model)

We will have a 10 gph, 30 gph, 60 gph (this model), 90 gph, 200 gph and 400 gph (we can do custom sized based on customers needs) each of these skids will have up to 4 stages based on customer needs

Live in person demos start 4/19/21

Message me for details!

46 Likes

It’s taken forever but it was all worth it!

Rome wasn’t built in a day

8 Likes

It pumps! Can you do terp strip from heptane with it?

What’s the ballpark cost on one of the smaller skids?

7 Likes

Yes, I think hydro carbons are best for terp strip tbh

I’ve found with my clean up SOP heptane is easier to remove then ethanol from the final terpene product

The 10/15 gph will be around 40k

30 will be around 70

60 will be around 100k

We’re still getting our pricing together on the larger skids

These will all come c1d1, hydro carbon membrane upgrades will run around 2-5k depending on the model you have

The hydro carbon membranes will run any of the solvents I listed

The ethanol ones will only run alcohols

Were also working to develope a membrane CRC stage with a Lenticular carbon filter and inline CRC

8 Likes

That’s a really sexy-looking piece of kit.

How many amps does your 400 GPH skid need?

I assume the GPH numbers are with Ethanol.

What should I multiply those numbers by to get a rough GPH for Heptane?

4 Likes

The 400 single stage would take around 45-50 amps 3 phase 480, when it runs it wouldn’t use anywhere near that amperage though

The heater/chiller you use to keep the system at temp will use more electricity based on what model you choose (we can help you size the right size heater chiller for the job. You need heating for the cleaning before shutdown)

Ballpark how many kW of heat do you need for a 400 gph?

Ditto cold, and at what temp?

I’m saying fuck it and making a huge portion of our equipment custom, so I’ll just build whatever it requires and take the kW off the system loop.

1 Like

There really isn’t much heat generated besides the friction that the high pressure valve creates, id guess 2 or 3 kw would be more then enough to keep your system at temp ill get you some better #s on that soon im working on calculating the heat increase based off the flow and pressure

The heating you shouldn’t need more then 5 - 10kw

Our cleaning and shut down sop has you push clean solvent through the system (room temp) to get any remaining crude out, you close off the membranes then use the heat exchanger bypass with the heater to heat up fresh solvent (you recirculate till you’re to desired temp) to the max temp of the membranes then push that across the membrane to clean them then shut down

Heating requirement really comes down to how long you want to wait to heat up fresh solvent

Our PLC skids will do this automatically and we’re even working on heater chiller control integration with certain heater chiller combos (like julabo and polyscience)

3 Likes

From my trials on heptane it runs around the same speed as ethanol

Heres room temp winterization in heptane with the hydro carbon membrane

6 Likes

Sounds like built in CIP. I like it. That’s a feature that makes life a lot easier.

3 Likes

We offer a 1 year warranty on all our systems

Part of the requirement of the warranty is for you to keep maintenance logs so if you have a problem and we have to come it we have logs to look at

(99% of the time ppl have problems because they don’t keep a proper cleaning schedule)

The PLC system keeps logs of this automatically which makes life 10x easier for you

5 Likes

Do you have data sheets from the manufacturer of those pump heads saying they’re cool for pumping liquid alkanes?

1 Like

These pumps are used in the oil&gas industry and are approved for hydro carbon use

The pump is constructed of a SS 304 body with ceramic pistons and ptfe seals, it cannot spark

PSI is reviewing our skid and has no problem with these pumps as they’re designed to be used in gas industry in C1D1 environments

https://www.catpumps.com/oil-gas

If you’d like to read more about the pumps we use from the manufacturer youre more then welcome to see some of the applications they’re used in at the link above

4 Likes

Whats really cool about Cat is you can call them and tell them your exact application and pressures and they will quote you the exact pump you need

They’re a legit company who stocks 99% of there stuff so if we ever need anything we can get it next day aired from the mid west (obviously you’re in Canada so transit times will be different)

We’re planning on stocking replacement membranes too so we can next day air membranes to ppl who need them

3 Likes

It does not appear that you have the class I div I electrical interface

with motor attached yet. There seems to be about an extra 10K

in explosion proof goodies, the appropriate gas detector 1.5K and another 15K Factory Mutual stamp missing? Controller will need

a NEMA 4x SSbox…like half the job is missing. I’m just pointing this out for your liability which you seem to be aware of. Final end product may be a bit more expensive,

I’d like to see a demo? Location?

Note: (in his latest post-edits KofK addresses all these issues including certification: “reviewed by PSI for C1D1 certifications.” )

2 Likes

Everything we need is there, not sure what you’re talking about

The VFD is mounted outside the control room and you run conduit to the c1d1 Larson controller

We need to finish the wiring, there’s no more c1d1 components required though

This demo unit will be installed outside under an awning which is why we’re not too worried about full c1d1 on this one

Demos will be in Grass Valley, CA or over the internet

1 Like

I got a shitty rep who didn’t like the demon lettuce and told me “no quote” when I asked for an C1D2 pump for heptane or ethanol. Should have tried a different rep

This is how we’re building our entire system. One big set of PLC cabinets on the other side of the wall from the extraction room.

6 Likes

You’d be surprised how expensive c1d1 VFDs are lol

This is how were going to do it too on the big systems with PLC

These smaller systems have a Larson controller that controls the VFD with speed control and an on and off

There’s a way around that though. Inerting is your friend.

4 Likes

![]()